Step by Step Guide to the Wire Harness Manufacturing Process

2026-04-05 12:17You start the wire harness manufacturing process by following clear steps like design, prototyping, wire cutting, stripping, assembly, and testing. A wire harness, sometimes called a cable harness, keeps electrical systems organized and safe in cars, electronics, and industrial machines. The cable harness market keeps growing, reaching over $93 billion in 2023, with the automotive industry leading the way. Xiamen Evershine Electronic Technology Co., Ltd. stands out for delivering cable harness solutions with top quality, fast turnaround, and custom designs. They use advanced tools and strong quality control to make sure every cable harness meets your needs. Close teamwork with you helps create the right cable harness for each project.

The table below shows key facts about the cable harness industry:

Key Takeaways

Wire harnesses organize and protect electrical systems in many industries, especially automotive.

The manufacturing process includes design, prototyping, material sourcing, assembly, testing, and shipping.

Good design and clear schematics help avoid mistakes and save time during production.

Using the right materials and connectors improves safety, durability, and performance.

Precise wire cutting, stripping, and labeling ensure reliable and easy-to-assemble harnesses.

Strong connections use crimping, soldering, or injection molding to suit different needs.

Organized assembly with proper layout, bundling, securing, and labeling speeds up production and reduces errors.

Thorough testing and quality control catch defects early and guarantee safe, long-lasting products.

Wire Harness Overview

What Is a Wire Harness

You can think of a wire harness as the main electrical system in many machines. In cars, a wire harness acts like the nerves and blood vessels in your body. It carries power and information to every part that needs it. A cable harness is a group of wires, cables, and connectors bundled together. This bundle keeps everything organized and safe from damage. You find wire harnesses in cars, computers, and even home appliances. As technology grows, wire harness manufacturing becomes more important. Modern vehicles use up to 8,000 meters of wiring and about 40 electronic control units. These systems help run safety features like airbags and anti-lock brakes. Without a cable harness, these features would not work well. Wire harnesses make sure power and signals move quickly and safely.

Note: Xiamen Evershine Electronic Technology Co., Ltd. leads the way in wire harness manufacturing. Their products use high-quality materials and advanced technology to meet the needs of today’s electronics and automotive industries.

Cable Harness Applications

You see cable harnesses in many industries. In the automotive world, a cable harness connects parts like lights, engines, and entertainment systems. In aerospace, cable harnesses help drones, satellites, and planes send power and data. Medical devices use cable harnesses to keep wires safe and organized in equipment like X-ray machines and surgical tools. In telecommunications, cable harnesses make sure routers and cell towers work without problems. Factories use cable harnesses in robots and CNC machines to keep wires neat and protected. Even in construction, cable harnesses help organize wiring inside buildings.

Automotive: Connects airbags, lights, engines, and more.

Aerospace: Powers and controls aircraft and satellites.

Medical: Keeps wires safe in diagnostic and imaging devices.

Telecommunications: Organizes wiring in routers and towers.

Manufacturing: Routes wires in machines and robots.

Construction: Bundles and protects building wiring.

Cable harnesses play a key role in every industry that uses electronics. As new technology appears, cable harness design and materials keep improving.

Key Components

When you look at a cable harness, you find several important parts. Each part has a job in making sure the system works well:

Wires and Cables: Carry power and signals.

Connectors: Join wires to devices or other cables.

Terminals: Attach wires to connectors or equipment.

Insulation: Protects wires from heat, moisture, and damage.

Sheaths and Sleeves: Bundle wires together for safety and order.

Labels and Markers: Help you identify each wire or cable.

Wire harness manufacturing uses these parts to build strong, reliable cable harnesses. Xiamen Evershine offers a wide range of cable harness products, from simple wire harnesses for home electronics to complex systems for cars and airplanes. Their team works with you to design cable harnesses that fit your needs, using the best materials and the latest technology.

Wire Harness Manufacturing Process

The wire harness manufacturing process includes several important steps. You start with design, move to prototyping, and then select the right materials. Each step helps you build reliable wire harnesses for many uses.

Design

Wire harness design is the first step in the manufacturing process. You work with engineers to create a plan that fits your needs. Xiamen Evershine uses advanced software and digital tools to make this step fast and accurate. You can see how your wire harness will look and work before building it.

Requirements

You begin by listing all the requirements for your wire harness. You decide how many wires you need, what type of connectors to use, and what the harness must do. You also think about the space where the harness will fit and the environment it will face. For example, a harness in a car engine needs to resist heat and vibration. Xiamen Evershine’s team works with you to understand every detail. This close teamwork helps avoid mistakes and saves time later.

Schematics

Next, you create schematics. These are drawings that show how each wire connects to other parts. Schematics help you see the path of electricity and signals. You use these drawings to check for errors and make sure everything matches your requirements. Digital tools let you change the design quickly if you find a problem. This step makes the wire harness manufacturing process more efficient and reduces the risk of costly mistakes.

Bill of Materials

After the schematics, you make a bill of materials (BOM). The BOM lists every part you need, such as wires, connectors, terminals, and labels. You use the BOM to order the right materials and keep track of costs. Xiamen Evershine uses the BOM to plan production and make sure nothing is missing. This careful planning helps you avoid delays and keeps the manufacturing process on schedule.

Tip: A clear BOM helps you control costs and makes it easier to build the wire harness correctly.

Prototyping

Prototyping is the next step in the wire harness manufacturing process. You build a sample harness, called a wire harness prototype, to test your design. This step lets you find and fix problems before making many harnesses.

Sample Build

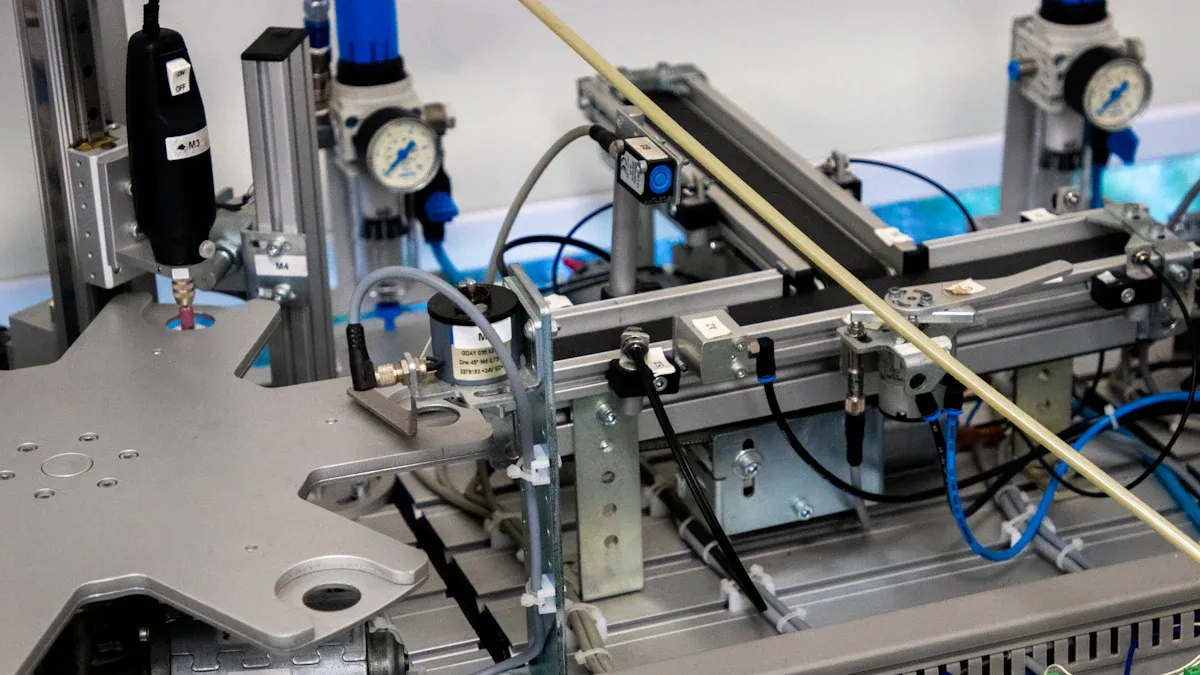

You use the design and BOM to build a sample harness. Xiamen Evershine uses both manual skills and automated machines for this step. For example, automatic cutting and stripping machines make wire processing fast and precise. Ergonomic workbenches help workers build long harnesses with high accuracy. In one project for an amphibious aircraft, the team simplified the design during prototyping. This change made the harness lighter, easier to assemble, and less expensive to produce.

Testing

After building the prototype, you test it to make sure it works. You check for electrical problems, such as short circuits or broken connections. You also test the harness in real-world conditions, like heat, cold, or vibration. Xiamen Evershine uses advanced testing equipment to speed up this step. For example, testing time for aircraft harnesses dropped from weeks to just a few days by using better tools and fewer workers. This fast testing helps you get your product to market sooner.

Industry trends show that rapid prototyping is growing fast. You can now make and test new designs quickly, which helps you stay ahead of competitors. The market for rapid prototyping materials is growing at over 7% each year. This growth comes from the need for faster product development and more custom parts.

Material Sourcing

Choosing the right materials is a key part of the wire harness manufacturing process. You need wires and connectors that match your design and work well in your application. Xiamen Evershine uses high-quality materials to make sure your wire harnesses last a long time.

Wire Selection

You select wires based on size, insulation, and how much power they must carry. Some wires need to resist heat, moisture, or chemicals. You also choose colors to help identify each wire. Xiamen Evershine helps you pick the best wires for your needs. Using the right wires improves safety and performance.

Connector Selection

Connectors join wires to devices or other harnesses. You choose connectors based on size, shape, and how much current they must handle. Some connectors need to be waterproof or easy to disconnect. Xiamen Evershine offers many connector options for custom wire harness projects. Good connectors make assembly easier and reduce the risk of failure.

Note: Material customization is important in custom wiring harness manufacturing. You can choose special wires or connectors for unique jobs. This flexibility helps you solve tough problems and meet strict standards.

Advanced manufacturing uses digital tools to plan and track every step. You get better quality and faster delivery. Xiamen Evershine combines automation with skilled workers to give you the best results. This approach helps you get your wire harnesses quickly and at a good price.

The wire harness manufacturing process at Xiamen Evershine focuses on customization, speed, and quality. You work with experts who use the latest technology and high-quality materials. This teamwork helps you get reliable wire harnesses for any job, from cars to data centers.

Wire Preparation

Wire preparation is a key step in Wire Harness manufacturing. You need to make sure every wire is the right length, has clean ends, and is easy to identify. This step sets the stage for a safe and reliable wire harness.

Cutting

You start by cutting wires to the correct length. Precision matters here. If a wire is too short, it will not reach its destination. If it is too long, it can cause clutter and even safety risks. In Wire Harness manufacturing, you can use both manual and automated cutting methods.

Manual cutting uses hand tools. This method works well for small batches or special wires. It gives you flexibility but takes more time. Automated cutting machines use programmed settings. These machines cut wires quickly and with high accuracy. You get uniform pieces every time. Automated cutting is best for large orders and helps you keep up with tight deadlines.

Automated cutting helps you achieve the consistency needed for quality Wire Harness manufacturing. Manual cutting still plays a role when you need flexibility or have unique requirements.

Stripping

After cutting, you need to strip the insulation from the ends of each wire. This step exposes the metal core so you can attach connectors or terminals. In Wire Harness manufacturing, you can choose from several stripping methods.

Manual stripping uses simple hand tools. This method works well for thicker wires or when you need to be careful. It costs less but takes more time. Mechanical stripping uses machines to remove insulation. These machines handle many wires at once and keep the process fast and uniform. For very high volumes, advanced machines like shredders or granulators can process wires quickly and with great precision.

Despite the rise of automation, up to 90% of wire harness work still uses manual methods. Manual stripping gives you control and adaptability. Automation, however, brings speed and repeatable quality. Both methods are important in Wire Harness manufacturing.

Labeling

Labeling is the final step in wire preparation. You add labels or markers to each wire. This step helps you track every wire during assembly and later maintenance. Clear labeling reduces errors and saves time.

You can use printed labels, color codes, or even barcodes. Automated labeling machines can print and apply labels quickly. Manual labeling lets you handle special cases or custom requests. In Wire Harness manufacturing, good labeling supports traceability and quality control.

Tip: Always double-check your labels before moving to the next step. Accurate labeling prevents mix-ups and ensures your wire harness works as planned.

Wire preparation combines careful cutting, precise stripping, and clear labeling. These steps help you build safe, reliable, and high-quality wire harnesses. Xiamen Evershine uses both manual skill and advanced machines to give you the best results in every project.

Terminal and Connector Attachment

Attaching terminals and connectors is a key step in Wire Harness manufacturing. You need strong, reliable connections to make sure your wire harness works well in any environment. Xiamen Evershine uses advanced methods to give you durable and water-resistant connections. Let’s look at the main ways you can attach terminals and connectors.

Crimping

Crimping is the most common way to attach terminals in Wire Harness manufacturing. You use a special tool to press the terminal onto the wire. This creates a tight bond without heat. Crimping works well for high-volume production and gives you fast, repeatable results.

You should always follow crimping standards. Use the right terminal, wire size, crimping die, and tool. This helps you get safe and reliable connections. Before crimping, make sure you strip the wire correctly. Good preparation is important for a strong crimp.

You can check your crimped connections by looking at them and by testing them. Here are some ways you make sure your crimps are strong and safe:

Visual inspection helps you spot defects right away.

Pull testing checks if the terminal stays attached under force.

Electrical testing measures resistance to make sure the connection is solid.

Using quality materials and following standards gives you consistent results.

Crimped terminals pass tough reliability tests. They meet pull-out force requirements of at least 450 N, even after heat or moisture exposure. Electrical resistance stays below 0.15 mOhms, which means your connection stays stable. Lubricants used in crimping stay stable up to 150°C, so your harness works in hot places. Even with different environments, crimped connections keep their strength.

Tip: Crimping is fast, cost-effective, and gives you a reliable connection for most wire harnesses.

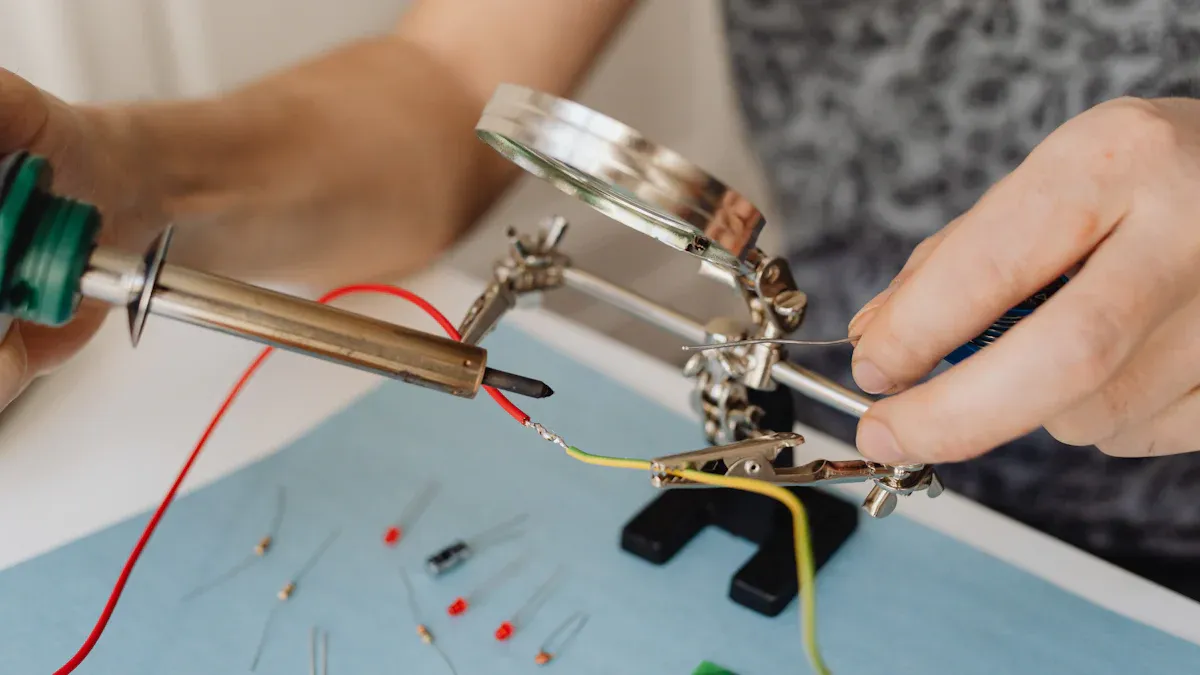

Soldering

Soldering is another way you can attach terminals and connectors in Wire Harness manufacturing. You use heat to melt a metal alloy called solder. The solder flows around the wire and terminal, then cools to form a solid joint. Soldering works well for small batches, repairs, or when you need a very secure connection.

You should use soldering when you need extra strength or when the connection will face vibration. Soldering takes more time than crimping, but it gives you a strong bond. Xiamen Evershine uses skilled workers and quality solder to make sure every joint is clean and reliable.

Injection Molding

Injection molding adds another layer of protection to your wire harness. You cover the terminal or connector with a molded plastic shell. This shell keeps out water, dust, and chemicals. Injection molding is perfect for automotive, outdoor, or harsh environments.

You get a custom fit and extra durability with this method. Xiamen Evershine uses advanced injection molding machines to make sure every harness meets strict standards. This process helps your wire harness last longer and work better in tough conditions.

Note: Choosing the right attachment method depends on your needs. Crimping is best for speed and cost. Soldering gives you extra strength. Injection molding protects your connections from the environment. Xiamen Evershine combines these methods to give you the best results in Wire Harness manufacturing.

Wire Harness Assembly Process

Layout

You start the wire harness assembly process by setting up the layout. This step helps you organize all the wires, connectors, and terminals before you begin putting them together. You use an assembly board, which is a flat surface with pegs or guides that show you where each wire should go. This board acts like a map for your cable and wire harness assembly.

A good layout makes the wire harness assembly process faster and more accurate. You can spot mistakes early and fix them before moving on. Many factories use the 5S method—organization, orderliness, cleanliness, standardize, and discipline—to keep the workspace neat. This method helps you find tools quickly and reduces wasted movement. When you follow a clear layout, you lower the chance of errors and make it easier to check your work.

Tip: Mistake-proofing designs, such as self-aligning parts and clear labels, help you avoid errors and speed up the assembly of the wiring harness.

You see that a well-planned layout not only saves time but also improves quality in the wire harness assembly process.

Bundling

Once you finish the layout, you move to bundling. Bundling means grouping wires together in neat, organized bunches. You use zip ties, tape, or sleeves to hold the wires in place. This step keeps the wire harnesses tidy and prevents tangling.

Bundling makes the wire harness assembly process smoother. It helps you handle the harness more easily and reduces the risk of damage. When you bundle wires, you also make the electrical harness assembly safer and more reliable. Mistake-proofing, like using color-coded ties or labels, helps you spot errors quickly.

Bundling reduces the number of parts you need to handle.

It makes the assembly of the wiring harness faster.

You can check for missing or extra wires at a glance.

A study from a packaging plant showed that using a kanban rack for bundling cut lead time by 7.1%. This means you can finish more wire harness assembly jobs in less time.

Securing

After bundling, you secure the wires to make sure they stay in place. You use clips, clamps, or brackets to attach the harness to the assembly board or the final product. Proper securing is key in the wire harness assembly process because it keeps everything stable during shipping and use.

Securing wires the right way improves both quality and speed. When you use the best securing techniques, you see fewer defects and less rework. You also keep production moving quickly. Key performance metrics, such as yield and first pass yield, show how well your securing methods work. High yield means most wire harnesses pass inspection the first time. This saves you time and money.

When you secure the harness well, you also reduce downtime and increase on-time delivery. Xiamen Evershine focuses on these steps to give you high-quality wire harnesses with fast turnaround. Their streamlined wire harness assembly process ensures every product meets strict standards.

Labeling

Labeling is a key step in the wire harness assembly process. You use labels to identify each wire, connector, and branch in your wire harness assembly. Good labeling helps you avoid mistakes and makes repairs easier later. When you follow the right labeling steps, you improve the quality of your cable and wire harness assembly.

You start labeling right after you finish securing the wires. You can use printed labels, color codes, or even barcodes. Each method has its own benefits. Printed labels give you clear text. Color codes help you spot wires quickly. Barcodes let you track parts with a scanner.

Here are some reasons why labeling matters in the wire harness assembly process:

You reduce the risk of connecting wires to the wrong place.

You make it easier to check your work during inspections.

You help future technicians fix or upgrade the harness.

You support traceability, which is important in Wire Harness manufacturing.

You can use different tools for labeling. Some companies use automatic label printers. These machines print and stick labels fast. Others use manual methods for custom jobs. Xiamen Evershine uses both, depending on the project size and customer needs.

Tip: Always double-check your labels before moving to the next step in the wire harness assembly process. A small mistake can cause big problems later.

The wire harness assembly process at Xiamen Evershine includes strict labeling rules. You follow a clear system so every wire and connector has the right label. This system helps you keep the wire harness assembly organized from start to finish.

Labeling is not just about putting a sticker on a wire. You need to follow the plan from the design stage. Each label matches the schematic and the bill of materials. This way, you keep the wire harness assembly process smooth and error-free.

When you use good labeling practices, you save time during the final inspection. You also make sure your wire harness assembly meets industry standards. Xiamen Evershine’s focus on quality means every step, including labeling, gets careful attention. This approach helps you deliver reliable products in every Wire Harness manufacturing project.

Testing and Quality Control

In-Process Inspection

You need strong in-process quality control of wire harness to catch problems early. During Wire Harness manufacturing, you check each step as you build the harness. This helps you find mistakes before they become bigger issues. You use visual checks, measurements, and sometimes automated tools like AOI (Automated Optical Inspection) or X-ray machines. These tools help you spot defects that are hard to see with your eyes.

In-process quality control of wire harness gives you many benefits:

You lower defect rates and improve yield.

You reduce scrap and save on labor costs.

You keep your supply chain accurate by catching errors early.

You build a quality-focused team through regular training.

You use data to improve your process and prevent future problems.

You track key metrics like defect rates and customer satisfaction. This helps you see how well your quality inspection works. When you use in-process quality control of wire harness, you make sure only good products move to the next step.

Tip: Early detection of defects saves time and money in Wire Harness manufacturing.

Electrical Testing

Electrical testing checks if your wire harness works as it should. You use special machines to test for short circuits, open circuits, and correct wiring. This step is important in electrical harness assembly because it makes sure every wire carries power and signals the right way.

You connect the harness to a test board or use automated testers. These tools send signals through the wires and check for problems. If a wire fails, you fix it before moving on. Electrical testing helps you meet industry standards and keeps your customers safe.

Here are some reasons why electrical testing matters:

It finds hidden wiring errors that visual checks might miss.

It ensures your harness meets performance standards.

It reduces the risk of product recalls and customer complaints.

It supports continuous improvement by collecting test data.

You use electrical testing in every Wire Harness manufacturing project to guarantee quality and reliability.

Mechanical Testing

Mechanical testing checks the strength and durability of your wire harness. You want to know if the harness can handle bending, pulling, and vibration. This step is key for products used in cars, planes, or machines that face tough conditions.

You perform tests like pull tests, flex tests, and vibration tests. These tests show if the terminals and connectors stay attached under stress. Mechanical testing also checks if the insulation and sheaths protect the wires from damage.

Mechanical testing gives you these benefits:

It proves your harness can survive real-world use.

It lowers the chance of failures after shipping.

It helps you improve your design for future projects.

It supports your brand reputation by delivering reliable products.

Note: Combining electrical and mechanical testing in Wire Harness manufacturing reduces defects and boosts customer satisfaction.

Final Inspection

You reach the last step in Wire Harness manufacturing when you perform the final inspection. This step is where you make sure every harness meets the highest standards before it leaves the factory. The final quality control of the finished wiring harness is your last chance to catch any problems. You want to deliver only the best products to your customers.

During the final quality control of the finished wiring harness, you check every detail. You look for visual defects like scratches, missing labels, or loose connectors. You also confirm that each wire is in the right place and that all labels match the design. You use checklists to guide your inspection. These lists help you remember every point you need to check.

You also test the harness one more time. You use electrical testers to make sure there are no short circuits or open wires. You check that every connection works as planned. If you find a problem, you fix it right away. This step in Wire Harness manufacturing helps you avoid costly returns or unhappy customers.

The final quality control of the finished wiring harness includes mechanical checks. You bend and twist the harness to see if it holds up under stress. You make sure the insulation stays in place and that connectors do not come loose. These tests show that your harness can survive real-world use.

You document every result from the final quality control of the finished wiring harness. You keep records of each test and inspection. This documentation helps you trace any issues back to their source. It also proves to your customers that you follow strict quality standards.

At Xiamen Evershine, you see a strong focus on the final quality control of the finished wiring harness. Their team uses advanced tools and follows detailed procedures. They make sure every product meets or exceeds industry standards. This commitment to quality sets them apart in Wire Harness manufacturing.

Tip: Always take your time during the final quality control of the finished wiring harness. Careful inspection now saves time and money later.

A good final inspection process helps you build trust with your customers. You show them that you care about quality in every step of Wire Harness manufacturing. When you follow these steps, you deliver safe, reliable, and long-lasting wire harnesses every time.

Packaging and Shipping

Protective Packaging

You want your wire harnesses to arrive in perfect condition. In Wire Harness manufacturing, protective packaging plays a big role in keeping products safe during shipping. You use strong boxes, foam inserts, bubble wrap, and anti-static bags to protect each harness. These materials cushion the harnesses and prevent scratches, bending, or electrical damage.

To make sure your packaging works, you rely on several tests:

Compression testing checks how much weight a box can handle before it gets crushed.

Drop and impact testing simulates what happens if a package falls or gets bumped.

Vibration testing uses special tables to shake the package, just like it would move in a truck or plane.

These tests follow strict standards, such as ASTM methods. They give you real numbers, like how much force a box can take or how well it absorbs shocks. You use this data to improve your packaging and reduce product damage. When you choose the right packaging, you help ensure every wire harness reaches your customer safely.

Tip: Always match your packaging to the size and shape of your wire harness. Custom packaging reduces movement and keeps each harness secure.

Shipping Labels

Clear shipping labels help you track every order from the factory to your customer. In Wire Harness manufacturing, you print labels with important details, such as part numbers, order codes, and destination addresses. You may also use barcodes or QR codes for easy scanning.

Good labeling prevents mix-ups and speeds up sorting at warehouses. You can quickly find the right package and check its status. Labels also help with traceability. If you ever need to recall a batch or check a shipment, you can do it fast.

Note: Double-check your labels before shipping. Accurate labels mean fewer delays and happier customers.

Logistics

Fast and reliable logistics set Xiamen Evershine apart in Wire Harness manufacturing. You benefit from advanced systems that track inventory in real time. This means you always know what is in stock and where your order is.

You see several ways logistics improve your experience:

Inventory visibility lets you plan better and avoid delays.

Demand forecasting helps keep the right products ready for shipping.

Route optimization finds the quickest delivery paths, so your harnesses arrive sooner.

Real-time tracking with SMS updates keeps you informed every step of the way.

Carrier performance checks ensure your packages go with the most reliable shippers.

These practices lead to fewer shipping problems and faster turnaround. For example, real-time tracking has reduced delivery-related support calls by 23%. When you order from Xiamen Evershine, you get your wire harnesses quickly and can trust they will arrive on time.

Xiamen Evershine’s focus on logistics and packaging means you receive high-quality wire harnesses, safely and on schedule, every time.

After-Sales Support

Customer Service

You deserve support that goes beyond the sale. Xiamen Evershine offers customer service that helps you at every stage of your Wire Harness manufacturing project. When you have questions or need help, you can reach out to a dedicated team. They respond quickly and work hard to solve your problems. This approach builds trust and keeps your project on track.

Customer service surveys help Xiamen Evershine learn what you like and what you need. These surveys ask for your feedback after each support call or product delivery. The company uses this information to improve its service and make sure you stay satisfied. Fast response times and friendly support help you feel confident in your choice.

Good customer service in Wire Harness manufacturing means you get answers fast and feel supported every step of the way.

Technical Guidance

You may face technical questions during installation or use. Xiamen Evershine provides expert guidance to help you solve these challenges. Their team explains how to install, connect, and test your wire harnesses. You get clear instructions and practical tips that make your job easier.

Technical support does more than answer questions. It helps you avoid mistakes and keeps your equipment running smoothly. When you need advice, you can count on experienced engineers who know the details of Wire Harness manufacturing. This support helps you finish projects on time and avoid costly delays.

Customer feedback shows that strong technical guidance leads to better results. Companies that offer this help see higher repeat purchase rates and stronger customer loyalty. You benefit from a partner who cares about your success, not just the sale.

Quick answers to technical questions prevent project delays.

Ongoing support helps you adapt to new technologies.

Clear instructions reduce installation errors.

Maintenance Tips

Taking care of your wire harnesses helps them last longer and work better. Xiamen Evershine shares maintenance tips to help you protect your investment. You learn how to check for wear, clean connectors, and spot early signs of trouble.

Here are some simple tips for keeping your wire harnesses in top shape:

Inspect harnesses regularly for signs of damage or loose connections.

Keep connectors clean and dry to prevent corrosion.

Use proper tools when making repairs or adjustments.

Store spare harnesses in a cool, dry place.

Regular maintenance reduces downtime and helps you avoid unexpected costs in Wire Harness manufacturing.

Xiamen Evershine’s after-sales support gives you more than just products. You get a partner who helps you succeed, from the first order to long-term use. This commitment to service and guidance builds strong, lasting relationships in the Wire Harness manufacturing industry.

Continuous Improvement

Feedback

You play a key role in continuous improvement for Wire Harness manufacturing. Your feedback helps identify what works well and what needs change. Many companies use feedback loops and key performance indicators (KPIs) to track progress. When you share your ideas, you help improve quality, reduce waste, and boost customer satisfaction.

Regular feedback leads to real results. For example, employees in top manufacturing companies suggest 10-15 improvements each year. About 60-70% of these ideas get put into action. This high rate of implementation shows that your voice matters.

Reliable feedback depends on good data. Companies use standardized methods to collect and check information. They use audits and digital tools to make sure the data is accurate. This approach helps you spot problems early and fix them before they grow.

Process Optimization

Process optimization means making every step in Wire Harness manufacturing better. You use lean manufacturing tools like value stream mapping and 5S to find and remove waste. These methods help you save time, cut costs, and improve product quality.

Here is a table showing how lean manufacturing can change results:

You can see that process optimization brings big benefits. Companies like Toyota and Boeing have used these methods to speed up production and cut waste. Six Sigma and Kaizen help you reach high quality and steady improvement. When you use these tools in Wire Harness manufacturing, you deliver better products and keep customers happy.

Tip: Use visual management and digital tracking to spot issues quickly and keep your process running smoothly.

Training

Training helps you and your team stay sharp in Wire Harness manufacturing. You learn new skills, practice with modern tools, and keep up with the latest technology. Training covers technical skills, digital systems, and soft skills like teamwork and communication.

Here are some ways training makes a difference:

Technical programs teach you how to use equipment and follow quality standards.

Ongoing lessons help you master robotics, automation, and digital tools.

Soft skills training builds strong teams and improves problem-solving.

Mentorship pairs new workers with experts for faster learning.

Cross-training lets you work in different roles, making the team more flexible.

Companies that invest in training see big gains. For example, plants with strong training programs report 24% higher profit margins and 21% lower employee turnover. At Siemens, training led to a 140% jump in productivity and a 75% drop in defects.

Continuous training supports a culture of improvement. You help your company grow, and you build your own career in Wire Harness manufacturing.

You now understand each step in the cable harness journey, from design to shipping. A cable harness keeps your electronics safe and organized. Xiamen Evershine gives you cable harness solutions with precision, speed, and custom support. You can trust their cable harness expertise for any project. Use these cable harness best practices to improve your own cable harness results. For more cable harness details or to order, contact Xiamen Evershine. Your cable harness success starts here! 🚗

FAQ

What is a cable harness?

A cable harness is a group of wires or cables bundled together. You use it to organize and protect electrical connections. Cable harnesses help you keep systems safe and make installation easier in many industries.

Why is cable harness important in Wire Harness manufacturing?

Cable harnesses help you reduce errors and save time during assembly. In Wire Harness manufacturing, you use them to keep wires organized. This makes your products safer and more reliable.

Where do you use a cable harness?

You find cable harnesses in cars, computers, and home appliances. You also use them in medical devices and industrial machines. Cable harnesses help you manage complex wiring in many applications.

How do you test a cable harness?

You test a cable harness by checking for electrical problems. You use machines to look for short circuits or broken wires. In Wire Harness manufacturing, you also check the strength and durability of each harness.

Can you customize a cable harness?

Yes, you can customize a cable harness for your project. You choose the wire type, length, and connectors. Wire Harness manufacturing companies like Xiamen Evershine help you design cable harnesses that fit your needs.

How does Wire Harness manufacturing ensure quality?

You follow strict steps in Wire Harness manufacturing. You inspect each cable harness during and after assembly. You use electrical and mechanical tests to make sure every harness meets high standards.

What materials do you use in a cable harness?

You use copper or aluminum wires, plastic insulation, and strong connectors. In Wire Harness manufacturing, you select materials that match your application. This helps your cable harness last longer and work better.