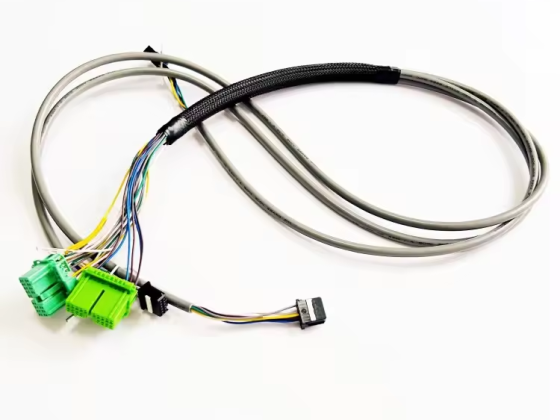

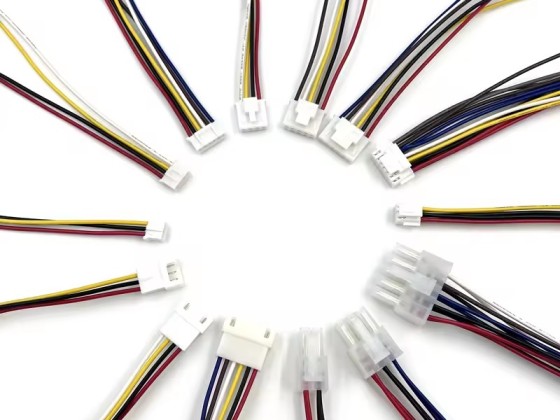

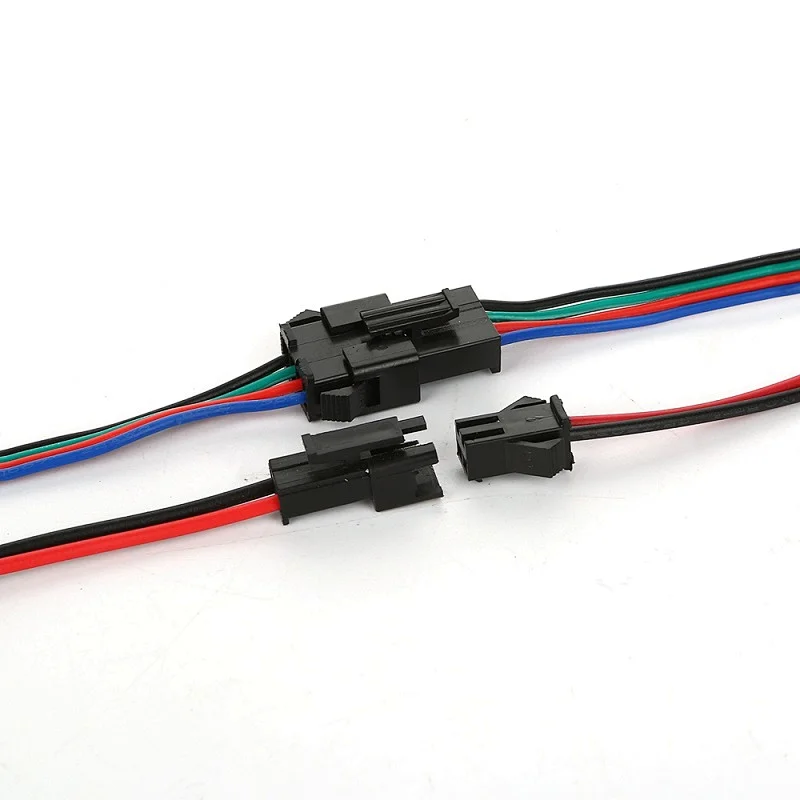

Factory 2.54mm Connector wire stripper Led Wire Harness

Factory 2.54mm Connector wire stripper Led Wire Harness. Our wholesale LED cable assemblies feature JST/Molex LVDS 2.54mm pitch connectors with a versatile 2-20 pin range, designed for use in LCD display wire harnesses. These high-quality cable assemblies ensure reliable and efficient data transmission, perfect for enhancing the performance of your display systems.

- Evershine

- Xiamen

- 7~15 days

- 100000pcs/month

- Information

What is cable harness?

A cable harness, also known as a wire harness, wiring harness, cable assembly, wiring assembly or wiring loom, is an assembly of electrical cables or wires which transmit signals or electrical power.

Otherwise referred to as a cable assembly, wire harness, wiring loom, or wiring assembly, a cable harness is an assembly of electrical wires or cables that conveys electrical power or signals. The cables are tied together with one or more of the following: cable ties, straps, electrical tape, cable lacing, conduit, a weave of extruded string, or sleeves.

Cable assemblies are groups of cables which are arranged into a single unit for a particular purpose. Cable assemblies are also referred to as cable harnesses or wiring looms.

How is a wiring harness created?

The electronic contents inside an automobile are increasing day by day and posing newer challenges in terms of managing the wiring harnesses that connect them.

A wire harness is a specially designed system that keeps numerous wires or cables organized. It is a systematic and integrated arrangement of cables within an insulating material.

The purpose of the wiring assembly is to transmit a signal or electrical power. Cables are bound together with straps, cable ties, cable lacing, sleeves, electrical tape, conduit, or a combination thereof.

What is the Wire Harness Assembly Process?

1.Wire Preparation. Cut the wires to the required lengths based on the design specifications.

2.Crimping or Soldering.

3.Terminal Assembly.

4.Harness Routing and Bundling.

5.Testing and Inspection.

6.Protective Covering

7.Labeling and Marking.

8.Final Quality Check and Packaging.

painless performance wire harness

wire harness manufacturing

custom wire harness

melted cause by fire wire harness

n20 high pressure fuel pump wire harness

power acoustik wire harness for pd-454b

wire harness connector

wire harness wrap