What Is the Difference Between Cable Assembly and Wire Harness?

2025-11-12 10:10In today’s fast-evolving manufacturing and electronics industries, the terms “cable assembly” and “wire harness assembly”are often used interchangeably. However, as systems become more complex and automation advances, the subtle but significant differences between these two have become increasingly important.

For any company dealing with electrical connectivity, signal transmission, or power distribution, understanding the distinction is not just a matter of terminology—it’s a question of performance, reliability, and competitiveness.

1. Understanding the Difference: Cable Assembly vs. Wire Harness Assembly

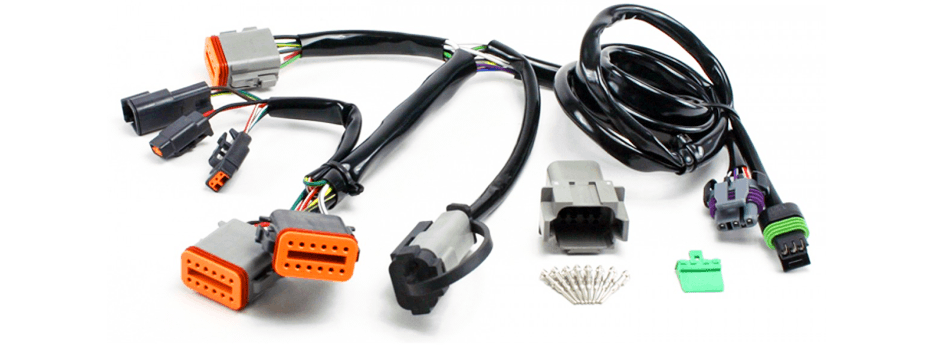

A cable assembly generally refers to one or multiple insulated cables that are bundled together and protected by an external sheath, often with pre-installed connectors. It emphasizes signal integrity, power transmission efficiency, and environmental protection, making it ideal for harsh or high-performance environments such as telecommunications, industrial automation, aerospace, and marine applications.

In contrast, a wire harness assembly is a structured bundle of individual wires, each organized, grouped, and routed according to a specific electrical or mechanical layout. The focus here is on organization and system integration, ensuring neat arrangement, easy maintenance, and reliable operation within complex electrical systems—commonly used in automobiles, home appliances, and mechanical equipment.

In short,

👉 Cable assembly focuses on “performance,”

👉 Wire harness assembly focuses on “structure.”

2. Evershine’s Perspective: From R&D to Smart Manufacturing

Founded in 2015, Xiamen Evershine Electronic Technology Co., Ltd. has become a trusted high-tech enterprise specializing in wire and cable, wire harness assembly, and related connectivity solutions.

With years of R&D and production experience, Evershine has built a solid reputation for providing custom cable assembly and custom wire harness solutions for a wide range of industries, including telecommunications, home appliances, power automation, aerospace, automotive, and marine systems.

Evershine’s strength lies in three core areas:

R&D Innovation – The company’s dedicated engineering team continuously develops advanced cable harness assembly technologies that combine high-density design with multi-functionality to meet specific customer requirements.

Automated Manufacturing – Certified by the ISO9001 quality management system, Evershine’s factory integrates automated cutting, crimping, and testing equipment, ensuring that every product passes strict inspection before delivery.

Global Certification – All products comply with international standards such as UL, RoHS, and CE, meeting the stringent requirements of the European and North American markets.

Guided by the philosophy “Quality is our culture. Survive by quality, develop by integrity,” Evershine continues to set a high standard in both cable assembly and wire harness assembly manufacturing.

3. Market Analysis: Global Trends in Cable and Wire Harness Assemblies

| Parameter | Industry Overview | 2024 Data | Forecast (2025–2030) |

|---|---|---|---|

| Global Market Size | Steady growth | Cable assembly: USD 7.9 billion; Wire harness assembly: USD 10.1 billion | CAGR of 6.5% |

| Main Applications | Automotive, telecom, home appliances, aerospace, industrial automation | Automotive accounts for 42% | Rapid growth in automation & renewable sectors |

| Technology Trends | High-density design, lightweight materials, modular assembly | Hybrid electro-optical solutions gaining traction | Custom cable assembly becomes mainstream |

| Regional Distribution | Asia leads in manufacturing; North America & Europe lead in demand | China, Vietnam, Mexico are key production bases | North America shows rising demand for custom wire harness |

| Challenges & Opportunities | Rising material costs and supply chain uncertainty | Raw material costs up by 8% | Smart manufacturing and digital inspection as key breakthroughs |

As the table indicates, demand for customized connectivity systems is growing rapidly. Emerging industries such as new energy vehicles, 5G communication, and smart homes are driving the market for high-performance cable harness assembly solutions.

4. From Standardization to Customization: The New Industrial Shift

In the past, most wire and cable products followed standardized designs. Today, customers increasingly seek functional integration and modular compatibility. In response, Evershine has adopted a “design-driven customization” strategy to deliver more flexible and application-oriented solutions.

For example:

In an electric vehicle project, Evershine optimized conductor cross-sections and routing design, improving current efficiency by 12% and reducing overall weight by 15%.

In an industrial automation project, the modular cable harness assembly reduced assembly time by 30%, greatly enhancing production efficiency.

By focusing on real-world applications rather than one-size-fits-all products, Evershine has strengthened its global competitiveness and built long-term customer partnerships.

5. Quality First: Every Step Ensures Reliability

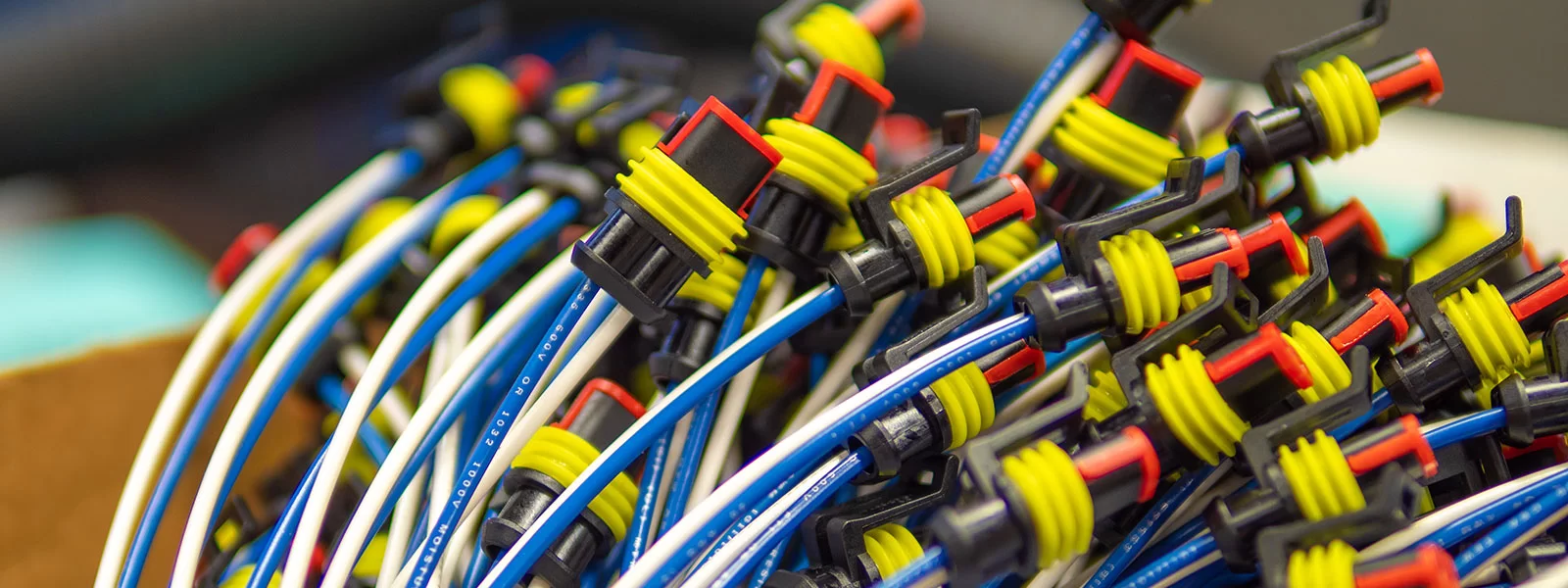

At Evershine, every wire counts. From raw material inspection, cutting, stripping, and terminal crimping to final assembly, all processes are carefully monitored using smart detection and automation systems.

The company also employs a comprehensive quality verification framework that includes:

Electrical Performance Testing – Ensuring signal integrity and EMI resistance

Pull and Durability Testing – Confirming mechanical strength

Environmental Simulation – Testing performance under extreme heat, humidity, and vibration

Full Traceability System – Creating a digital record for every custom wire harness produced

Through these rigorous controls, Evershine doesn’t just deliver products—it delivers confidence and reliability.

6. FAQ: Frequently Asked Questions

Q1: What’s the main difference between cable assembly and wire harness assembly?

A1: Cable assembly is designed for power or signal transmission with protective sheathing, suitable for high-performance environments. Wire harness assembly organizes multiple wires into bundles for system-level connections and internal wiring.

Q2: What’s the process for a custom cable assembly project?

A2: It typically includes requirement analysis, schematic design, prototype testing, small-batch production, and full-scale manufacturing—Evershine provides full engineering support throughout.

Q3: Where are custom wire harnesses commonly used?

A3: They are used in automotive systems, home appliances, industrial machinery, and medical devices requiring complex circuit layouts.

Q4: How does Evershine ensure the reliability of its cable harness assembly?

A4: By using internationally certified components, automatic testing systems, and environmental stress testing to guarantee durability and stable performance.

Q5: Why choose Evershine as your supplier?

A5: Evershine offers over 10 years of experience, international certifications, fast delivery, and competitive pricing for both custom cable assembly and custom wire harness solutions.

7. Looking Ahead: Evershine’s Future Vision

Over the next five years, the cable and wire harness industry will undergo a major transformation driven by smart manufacturing, eco-friendly materials, and digital traceability.

Evershine plans to fully integrate smart inspection and MES systems by 2026, creating a digitalized factory where design, production, and quality management are connected in real-time. The company is also expanding partnerships in Europe and North America to provide advanced cable harness assembly solutions for the new energy, medical, and aerospace sectors.

8. Conclusion: Connecting the Future with Quality and Integrity

In a world defined by connectivity, every cable and every harness serves as the lifeline of energy and information flow. The evolution of cable assembly and wire harness assembly reflects the continuous refinement of modern industry.

Evershine understands that what truly connects systems is not just copper and insulation—it’s trust, precision, and innovation.

With a deep commitment to excellence, Xiamen Evershine Electronic Technology Co., Ltd.will continue to develop world-class custom cable assembly and custom wire harness solutions that empower customers to build safer, smarter, and more efficient electrical systems.

Choosing Evershine means choosing quality, reliability, and a long-term partnership for success.