Beyond Connection: Partnering with a Wire Harness Factory for Innovative Cable Assembly Solutions

2025-11-05 10:24Introduction: Redefining the Partnership

In today's rapidly evolving fields of IoT, new energy, robotics, and high-end equipment manufacturing, simple wire connections are far from sufficient. Modern advanced equipment urgently requires highly integrated, environmentally resistant, intelligent, and highly reliable Custom Wire Harness Cable Assembly. This is not just about transmitting power or signals; it is about ensuring the stable operation of the entire system's "neural network." Now, we must reflect: Is your current Cable Assembly supplier merely passively executing design drawings, or are they a strategic partner that can proactively participate in design optimization, provide value engineering analysis, and jointly tackle technical challenges with you?

Since its establishment in 2015, Xiamen Evershine Electronic Technology Co., Ltd. has been determined to transcend the role of a traditional supplier. We are an enterprise professionally engaged in the R&D, production, and sales of wires, cables, and Wire Harness products, widely used in critical fields such as communications, home appliances, power automation, aerospace vehicles, ships, and automobiles. We firmly believe that the core value of a truly modern Wire Harness manufacturer lies not in simple processing and manufacturing, but in its profound engineering wisdom, forward-looking problem-solving capabilities, and steadfast willingness to innovate together with its clients.

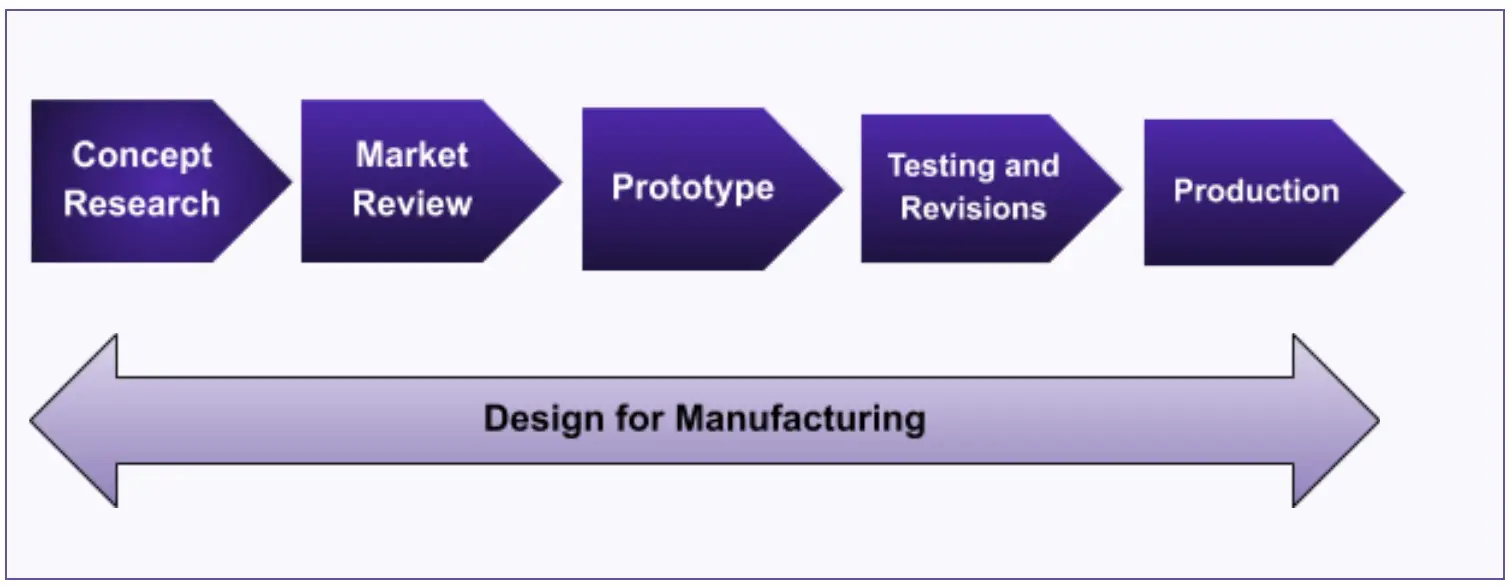

Part 1: Design Support from Concept to Mass Production – Accelerating Ideas to Reality

Introducing an engineering-capable partner at the initial project stage offers value far beyond cost savings. It fundamentally avoids design flaws and accelerates time-to-market.

Co-Design and Value Engineering: At Evershine Electronic, our collaboration begins at the blueprint stage. When you approach us with a concept for an Electrical Cable Assembly, our seasoned engineering team immediately engages, becoming an extension of your R&D force. We provide far more than just production; we offer deep design optimization support:

Connector Optimization: Based on your electrical requirements and budget, we leverage our extensive database and supplier network to recommend the most cost-effective and reliable connection solutions, avoiding both "over-engineering" and "under-engineering."

Harness Layout and Design for Assembly: Our engineers optimize the 3D routing of your Wire Harness from production and usability perspectives, ensuring easy installation and maintenance within the final equipment, and effectively preventing wear and interference.

Materials Science Advice: For different application environments (e.g., high temperature, humidity, oil, chemical corrosion), we recommend the most suitable wire, insulation, and sheathing materials. For instance, our Customized PVC Insulated Cable Assembly series can be tailored by adjusting the PVC formulation to meet specific temperature ratings, flame-retardant grades, or flexibility requirements, significantly enhancing product lifespan and reliability.

Rapid Prototyping and Agile Iteration: Speed is a critical competitive advantage in today's market. We understand that a functional prototype is crucial for project decisions and funding. Evershine Electronic is equipped with a professional rapid prototyping center, capable of delivering fully functional, well-crafted prototypes of Custom Wire Harness Cable Assembly within 2-3 working days after receiving your design data. This not only drastically accelerates your product development cycle but also provides a valuable opportunity for both parties to verify the design and perform iterative optimizations before mass production.

Part 2: Technical Expertise for Complex Applications – Conquering Harsh Environments

Our technical capabilities, honed over nearly a decade, have evolved into specialized Electrical Cable Assembly solutions for multiple high-growth industries.

In-Depth Look at Specific Industry Solutions:

High-Speed Data Harness Solutions: With the proliferation of 5G and AIoT devices, demands on data transmission rates and integrity are increasingly stringent. We specialize in producing data Cable Assembly for high-speed protocols like USB-C, HDMI, and Ethernet. Through precise impedance control, multi-layer shielding, and high-quality connectors, we ensure signals maintain low loss and low crosstalk over long distances, meeting the needs of high-definition video and data center applications.

High-Power Harness Solutions: For new energy fields like electric vehicles, charging piles, and energy storage systems, we provide specialized high-power Wire Harness. We focus critically on conductor current capacity, connection reliability, and overall high-temperature resistance and safety. Using high-specification copper, premium insulation materials, and crimping processes, we ensure stability even under high current flow, eliminating overheating risks.

Environmentally Resistant Special Harness Solutions: For applications in aerospace, ships, and outdoor industrial equipment, harnesses must withstand extreme challenges. Our specialized Customized PVC Insulated Cable Assembly and higher-performance product lines offer excellent resistance to water (IP67/IP68 ratings), oil, UV light, vibration, and extreme high and low temperatures (-55°C to 150°C). Whether facing salt spray in ship hulls or severe vibration in construction machinery, our harnesses perform reliably.

Advanced Processes and Full-Process Quality Verification:

Precision Manufacturing Processes: Our factory utilizes fully automatic terminal crimping machines, ultrasonic welders, waterproof overmolding equipment, and laser marking systems. These ensure consistency and reliability at every connection point, and clear, permanent cable identification.

Comprehensive Testing System: Quality is the foundation of Evershine Electronic's survival. Beyond basic continuity and hipot tests, we offer:

Automated Optical Inspection (AOI): Uses high-definition cameras to automatically inspect terminal crimp quality, wire sequence/color, and assembly correctness, eliminating human error.

Electrical Performance Testing: Performs TDR impedance testing, insertion/return loss testing for high-speed cables.

Environmental Reliability Testing: Simulates vibration, temperature cycling, salt spray, and other harsh conditions to verify the long-term durability of the Electrical Cable Assembly. All this is underpinned by our ISO9001 Quality Management System certification and adherence to relevant international product certification standards, safeguarding your products for global distribution.

Conclusion: An Invitation to Co-create the Future

Choosing Xiamen Evershine Electronic Technology Co., Ltd. means you will receive more than just a high-quality Custom Wire Harness Cable Assembly or a competitive quotation. You will gain a trusted engineering partner, a strategic ally committed to using its expertise to clear technical obstacles, reduce your total cost of ownership, and accelerate product innovation. We look forward to partnering with you to transform the next great product concept into a market-reality.

Take action now and start the conversation! Please leave your contact information. Our senior application engineer will promptly connect with you to provide a专属 technical solution and detailed quotation tailored for your large-scale project.

【Frequently Asked Questions】

Q1: How does Evershine Electronic typically engage during the co-design phase, and what information is required from the client?

A1: We recommend involving us during your product conceptual or detailed design phase. You need only provide basic electrical parameters (voltage, current, signal type), connector preferences, approximate layout space, and environmental requirements. Based on this, our engineers will provide a preliminary Wire Harness design sketch, connector selection advice, and cost analysis. This early collaboration maximizes the value of our expertise as a Cable Assembly specialist.

Q2: Can you support R&D projects with small volumes and high mix? What is the Minimum Order Quantity (MOQ)?

A2: We highly value collaboration with startups and R&D teams. For small-volume Custom Wire Harness Cable Assembly orders during the R&D phase, we offer highly flexible support without a mandatory high MOQ. We understand the importance of samples and pilot production and are committed to growing together through fast, high-quality small-batch services, laying the groundwork for future mass production cooperation.

Q3: What specific IP rating can your environmentally resistant harnesses, particularly for "waterproofing," achieve, and how is it validated?

A3: Our environmentally resistant Electrical Cable Assembly, especially types with waterproof connectors or waterproof overmolding, can be designed to achieve IP67 or IP68 ratings. This means they can be completely protected against water ingress under specified conditions (e.g., IP68: 1.5 meters underwater for 30 minutes). We rigorously validate this performance using internal waterproof test chambers and third-party testing institutions, providing corresponding test reports.

Q4: As a company founded in 2015, how do you ensure technical reliability for high-end sectors like aerospace and automotive?

A4: The year of establishment is not the sole measure of technical depth. Since our inception, we have established the core culture of "surviving by quality, developing by integrity," and systematically built our technical capabilities. We are certified to the ISO9001 International Quality Management System, the cornerstone of our process standardization and quality stability. Furthermore, our core engineering team possesses profound experience in relevant industries, and the Customized PVC Insulated Cable Assembly and special harnesses we produce for high-end sectors are selected, manufactured, and tested in strict compliance with the most stringent international industry standards, ensuring they meet or exceed reliability requirements.

【Global Custom Wire Harness & Cable Assembly Market Data Analysis & Outlook (2024-2029)】

The table below consolidates key data analysis and forecasts from authoritative sources on the global custom wire harness and cable assembly market, providing data-driven insights for your strategic planning and procurement decisions.

| Parameter | 2024 Status/Data | 2029 Forecast | CAGR | Implication for OEMs/Buyers |

|---|---|---|---|---|

| Global Market Size | $185.2 Billion | Projected ~$258.0 Billion | ~6.8% | Market is in a high-growth phase; securing a quality supply chain partner early is crucial. |

| Electric Vehicle Segment Share | ~22% | Projected to reach ~30% | ~12.5% | Exploding demand for high-power, high-voltage Electrical Cable Assembly; find factories with relevant technical expertise. |

| Data Communication Segment Share | ~18% | Projected to reach ~23% | ~9.5% | High-speed data Cable Assembly is another major growth driver; demands high signal integrity design capability from factories. |

| Customization Demand Ratio | Over 60% of orders are custom | Projected to exceed 75% | ~7.0% | Standard product space is shrinking; partnering with factories capable of providing Custom Wire Harness Cable Assembly is the norm. |

| Asia-Pacific Production Share | Over 70% | Projected to remain >72% | - | China remains the world's most important Wire Harness manufacturing base, offering significant supply chain advantages. |

| Technology Integration Trend | Lightweight, Modular Design | Smart Harnesses (with sensing/diagnostics), Sustainable Materials | - | Choosing R&D-focused manufacturers ensures ongoing access to innovative solutions like advanced Customized PVC Insulated Cable Assembly. |

Source: Synthesis and forecasts based on reports from multiple international market research firms (e.g., MarketsandMarkets, Grand View Research).

Conclusion: The data clearly depicts a vibrant and rapidly evolving market landscape. Future success will belong to those Custom Wire Harness Cable Assembly manufacturers that can integrate deep customization, cross-industry technical expertise, rigorous quality assurance, and agile service. Xiamen Evershine Electronic Technology Co., Ltd. is precisely such an ideal partner, ready to work alongside you and scale new heights.