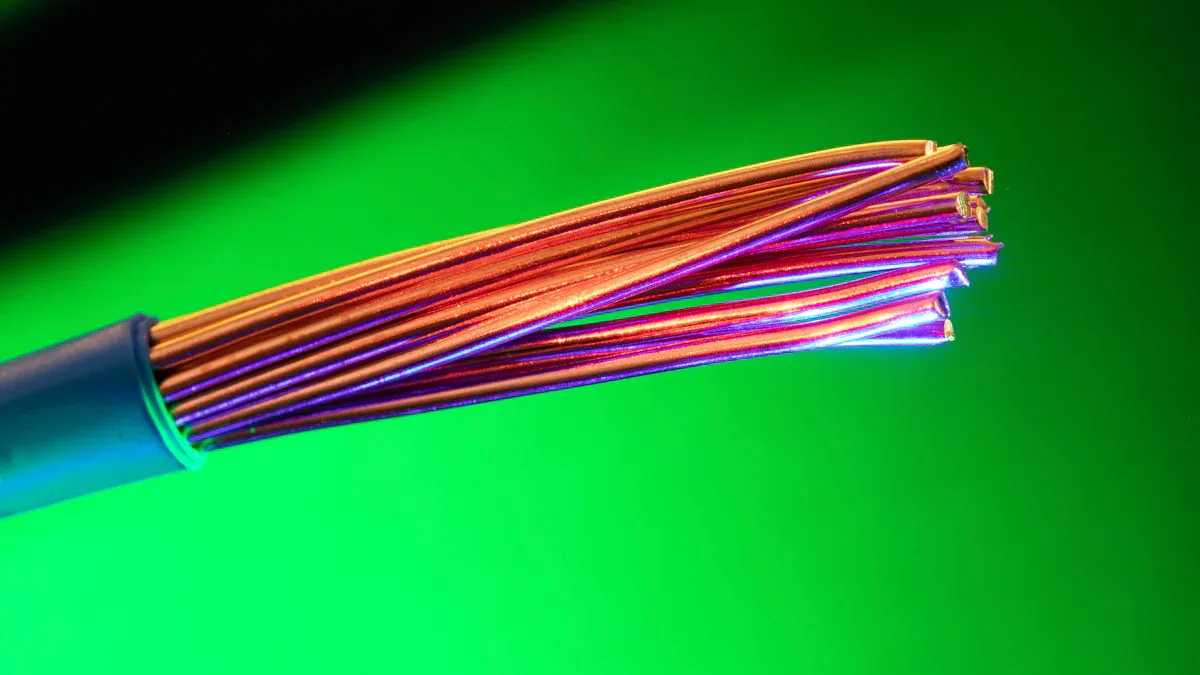

Looking to purchase copper wire harnesses? Not knowing these three facts could cost you dearly.

2026-02-25 10:42You can lose money and face safety problems if you choose Copper Wire Harness Assembly without knowing enough. Even a tiny error can cause things to break. This happens a lot with manual crimping, where mistakes happen up to 1.2% of the time. Automated crimping has fewer mistakes, only 0.08%. This helps you avoid spending extra money and wasting time. To stay safe, you should learn three important facts before you buy.

Key Takeaways

Always look for certifications like ISO 9001 and UL. These show the wire harnesses are safe and good quality.

Make your wire harness fit your project needs. Think about wire gauge, insulation, and how strong it is.

Pick suppliers who help you after you buy. Good service lets you fix problems fast and keeps your project moving.

Make sure your suppliers deliver on time. If they are late, your work can stop and you might lose money.

Know the rules and standards for wire harnesses. Following them helps you avoid mistakes and keeps things safe.

1. Copper Wire Harness Assembly Standards

Certifications & Compliance

You should make sure your supplier follows the right rules. Certifications prove a company cares about safety and quality. The most trusted certifications for Copper Wire Harness Assembly are below:

| Certification/Standard | Description |

|---|---|

| ISO 9001:2015 | Makes sure a company uses a quality system. |

| UL Approval | Checks safety and performance with outside tests. |

| IPC Standards | Sets rules for how electronics are made. |

| RoHS Compliance | Limits dangerous stuff to protect the environment. |

| REACH Compliance | Makes cable assemblies safer by controlling chemicals. |

| Conflict Minerals Compliance | Makes sure materials are gathered in a fair way. |

ISO 9001 and UL are the most used. ISO 9001 is about quality. UL checks safety and performance. Always ask to see proof of these certifications.

Manufacturing Quality

Good manufacturing means fewer problems and safer products. Companies like Star Engineering Inc., Kato Cable, and OneMonroe are known for quality.

"Kato Cable always gives high-quality products and meets tough rules. Their customer service is great—fast, smart, and very helpful."

OneMonroe follows ISO 9001:2015 and AS9100. They make sure every Copper Wire Harness Assembly is what customers need.

If a supplier does not follow strict rules, you could have electrical failures, safety risks, and expensive recalls. Bad design, weak materials, or poor assembly can cause big trouble.

Safety & Reliability

You want your wire harnesses to work safely every time. Good standards help you avoid common problems, such as:

Heat damage from high temperatures.

Damage from movement or shaking.

Rust from water.

Harm from chemicals.

Bad design or building.

Connectors wearing out.

Materials breaking down.

A good harness lowers the chance of electrical problems and keeps things working well. If you ignore standards, you could face recalls, downtime, or even legal issues. Always pick suppliers who follow the rules for Copper Wire Harness Assembly.

2. Customization & Specification Fit

Technical Requirements

Every wire harness must fit your project. If you pick the wrong wire gauge or insulation, your system might not work. You need to check some things before buying:

Durability: Choose harnesses that last in hard places. Copper is strong and lasts a long time.

Temperature Resistance: Some machines get very hot. Use harnesses that can take high heat.

Specific Use Cases: Each project is not the same. You may need heat resistance, chemical resistance, or both.

Many suppliers, like Copper & Optic, Y.C. Cable, and MJM Industries, make custom harnesses. They help you pick the right wire, insulation, and connectors for your job. Some companies also focus on custom designs and quick service.

| Manufacturer | Services Offered |

|---|---|

| Cables Unlimited | Custom cable design, rapid prototyping, all volume manufacturing |

| Meridian Cable | Custom wiring and harnesses, expert engineering |

| Conwire | Tailored harness solutions, over 100 years of experience |

| FCL | Cable and wire assemblies for many industries, strong logistics |

Regulatory Needs

You have to follow rules for every Copper Wire Harness Assembly. These rules change often. They tell you how to sort, check, and accept harnesses. Some important standards are IPC/WHMA-A-620, UL, SAE, and IATF 16949. Each industry, like cars or planes, has its own rules.

| Key Area | Impact of Regulatory Changes |

|---|---|

| Classification | Shows the newest industry agreement |

| Inspection Methodology | Makes checking better |

| Process Control | Gives more control in making things |

| Acceptance Criteria | New rules for what is good or bad |

Avoiding Mismatches

If you use the wrong harness, your system can break. You could have safety problems or pay a lot to fix things. Always check the specs and ask for custom choices. More companies want eco-friendly materials, smaller harnesses, and smart ways to make them. You can avoid mistakes by working with suppliers who know your needs and keep up with new ideas.

Tip: Always tell your supplier about your project. This helps them make the right harness for you.

3. Support & Delivery Reliability

After-Sales Service

When you buy a Copper Wire Harness Assembly, you need more than just the product. You want a supplier who helps you after you buy. Many buyers like extra services such as help with shipping and fixing problems. These services help you solve issues fast and keep things working. Top suppliers like Galaxy Wire & Cable and Custom Wire Industries give strong support and good warranties. They answer questions quickly and help you fix problems. Some companies, like SAISONIC and QL-Custom, have support all day and night. They also help in many languages and can track defects.

| Supplier | After-Sales Support Features |

|---|---|

| SAISONIC | Great customer service team, focus on happiness |

| QL-Custom | Help any time, many languages, fast answers, tracking |

Tip: Pick a supplier who gives clear warranties and quick help. This keeps your project moving.

On-Time Delivery

You need your wire harnesses to arrive when you expect. If they are late, your work can stop and you lose money. Problems like not enough copper or insulation, not enough workers, and higher costs can slow things down. You can use smart ideas to avoid these problems:

| Strategy | Benefits |

|---|---|

| Supplier Consolidation | Easier to manage, better planning |

| Just-in-Time Fulfillment | Less storage needed, track orders easily |

| Predictive Analytics | Warnings for delays, spot trends |

Good suppliers keep records and change plans when needed. They work with you to plan ahead and stop problems before they happen.

Operational Impact

If your supplier does not deliver or help you, your business can have trouble. You might have:

Delays in making things

Problems in the field

Expensive recalls

Hurt reputation

You can lower these risks by choosing suppliers with safe records, good shipping skills, and who can handle last-minute changes. Good partners help you make better products and avoid mistakes early. This saves you time and money.

Note: Always check a supplier’s past and ask about their help and delivery before you buy.

You should know three important things before buying copper wire harnesses. First, look at the wire gauge and material to keep things safe. Second, check if the insulation works for your project. Third, choose suppliers who have good quality systems and the right certifications. If you do not do these things, you could make expensive mistakes or get unsafe products. Always check if your suppliers have experience, give support, and are reliable. Making smart choices keeps your business safe and saves you money.

FAQ

What certifications should you check before buying copper wire harnesses?

You should look for ISO 9001, UL, and IPC standards. These show the supplier cares about safety and quality. Always ask for proof before you buy.

How do you know if a harness fits your project?

You must match the wire gauge, insulation, and connectors to your needs. Share your project details with the supplier. They can help you choose the right harness.

Why does on-time delivery matter for your business?

Late deliveries can stop your work and cost you money. Reliable suppliers ship on time. This keeps your project on track.

Can you get custom wire harnesses for special projects?

Yes! Many suppliers offer custom designs. You can ask for special materials, sizes, or features. Custom harnesses help your system work better.

What support should you expect after buying?

You should get clear warranties, fast answers, and help with any problems. Good suppliers offer strong after-sales service. This support keeps your business running smoothly.