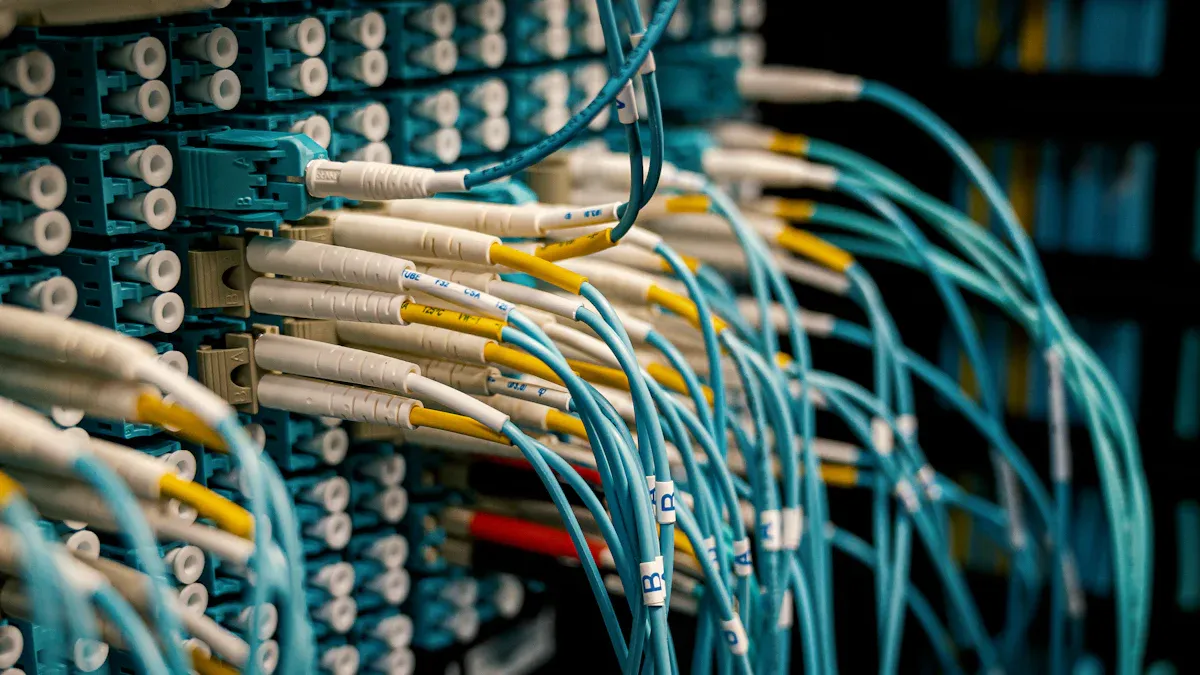

How to simplify cable assembly? Mastering these 3 tips is enough.

2026-02-18 10:22You can make cable assembly simple. Just try a few practical tips and watch the stress melt away. These methods work for anyone. Want a smoother process? Keep reading for easy solutions you can use today.

Key Takeaways

Putting cable assembly in one spot helps stop confusion and mistakes. Keep all materials together to track them better and check quality.

Using tools like Velcro ties and cable spines keeps cables neat and safe. This makes your workspace tidy and helps with easy maintenance. It also cuts down on downtime.

Use a step-by-step process for cable assembly to avoid mistakes and work faster. Test connections as you go to find problems early.

1. Centralize Cable Assembly

One Point of Contact

Making cable assembly easier is simple if you have one main place or person for all your cable needs. This helps stop confusion and lowers mistakes. When you keep everything in one spot, you get updates right away about what is happening, what materials you have, and what you need next. You also make fewer mistakes because you do not have to type in data by hand. If a problem comes up, you can find it and fix it quickly.

Tip: If you centralize cable assembly, you always know who to ask and where to find answers.

Here’s how centralizing helps:

| Benefit | Description |

|---|---|

| Real-time information | You get fast updates on process times and materials, so you stay on track. |

| Fewer manual errors | Using automation means you make fewer mistakes when entering data. |

| Better quality control | You can check and manage quality for better results. |

Unified Cable Grouping

If you put cables together in one group, it is much easier to install and take care of them. You save time, do less work, and keep your space safe and tidy. Grouped cables are easy to upgrade and do not break as often.

Maintenance is easier and upgrades are faster

There are fewer outages and less downtime

Workspaces are safer and cleaner

Simplified Management

You can centralize cable assembly by doing a few easy things:

Let trusted partners do the hard prep work.

Use digital tools to order and track parts.

Keep extra tasks in one place with pre-assembled parts.

If you keep things neat and in one spot, you will spend less time looking for things and more time working.

2. Organize and Secure Cables

Use Cable Ties and Spines

You need to keep cables neat and safe. Simple tools help a lot. Try using cable ties, Velcro straps, and cable spines. Each tool works best for different jobs.

Velcro ties can be used again. They are good for cables you move a lot. You can put them on and take them off fast.

Cable ties hold cables together tightly. They stop cables from getting tangled.

Cable spines and sleeves cover cables. This makes your setup look clean and protects the cables.

You can also use cable trays, conduits, clamps, and markers. These keep cables in place. Reusable ties are good for the planet. You use them many times, so there is less trash.

Tip: Velcro ties let you change your cable setup anytime. You do not need to cut or replace anything.

Built-In Channels

Many desks and workstations have built-in channels. These channels hide cables and make your workspace look nice. You lower safety risks like tripping and fires. You save money because cables last longer and stay safe.

| Benefit | Why It Matters |

|---|---|

| Neat appearance | Clients and coworkers will be impressed |

| Safety | Fewer trips and less cable damage |

| Efficiency | Find cables fast and work without distractions |

Neat Workspace

A clean workspace helps you focus better. Start by unplugging and removing old cables. Coil extra cable into loose loops so it does not get damaged. Use floor covers to keep cords along walls. Label both ends of each cable to help with troubleshooting. Try color coding for different types of cables. Keep extra labels nearby for quick fixes.

Note: Organizing cables cuts down on mess and makes cable assembly easier.

3. Follow Simple Cable Assembly Steps

Step-by-Step Process

You can make cable assembly much easier if you break it down into simple steps. When you follow a clear process, you avoid confusion and finish faster. Here’s a basic order you can use:

Cable Preprocessing: Cut wires, treat cables, remove foil, braid, strip, and tin the ends.

Terminal and Connector Processing: Crimp terminals, solder wires, and check each joint.

Assembly and Protection: Add shields, overmold, and use heat-shrink tubes.

Quality Control and Testing: Test for electrical problems and inspect the finished product.

Packaging and Shipping: Pack, label, and protect your cables for delivery.

Tip: Breaking the job into small parts helps you spot mistakes early and makes the whole process smoother.

Test as You Go

Testing at every stage keeps your cables working right. You should check insulation, solder joints, and connections as you build. Try these steps:

Test samples before you start.

Check connections during assembly.

Do a final test before shipping.

Use tools like continuity testers and resistance meters. Make sure your test gear works well. This way, you catch problems before they get bigger.

Fix Issues Early

If you find a problem, fix it right away. Common issues include open circuits, short circuits, and bad connectors. Early repairs save time and money. You avoid downtime and keep your cables reliable.

| Fault Type | What to Do |

|---|---|

| Open Circuit | Replace or re-terminate the cable |

| Short Circuit | Cut out and splice new section |

| Ground Fault | Seal with waterproof tape or tubing |

Note: Quick fixes during cable assembly lead to better results and fewer headaches later.

Bonus Tips & Mistakes to Avoid

Quick Wins

Want to make your next project even smoother? Try these quick wins from the pros:

Use Velcro straps for sensitive cables. They hold things together without crushing wires.

Invest in high-quality cable ties. Velcro ties work best because you can reuse them and avoid damage.

Keep cables off the floor. This stops tripping and keeps cables safe from shoes and carts.

Leave a little extra cable in a loop, called a service loop. This makes future changes easy.

Color-code your cables. You can spot the right one fast and avoid mix-ups.

Label both ends of every cable. Use heat-shrink labels or adhesive markers for a clean look.

Plan your layout before you start. Think about where each cable will go and how long it needs to be.

Use a cable stripper to remove the outer jacket without hurting the wires inside.

Try a label maker for neat, easy-to-read tags.

Tip: Always use the right tool for the job. A punch down tool or fish tape can save you time and effort.

Common Pitfalls

Many people make the same mistakes. Here’s what to watch out for:

Picking the wrong wire or cutting it too short.

Skipping the assembly drawing or not following instructions.

Crimping connectors the wrong way.

Soldering too hot or too cold, which can damage wires.

Forgetting wires or using the wrong hardware.

Tying cables too tight or too loose.

Note: Take your time and double-check each step. Careful work means fewer problems later.

You can make your job easier if you keep things together, stay organized, and follow easy steps. People get better results and do not need to fix things as much when they use these ideas. Look at the table below to see how it helps:

| Feature | Benefit |

|---|---|

| Service life | Lasts longer |

| Maintenance needs | Needs less work |

Try these tips now and see how easy cable assembly can be!

FAQ

What tools do I need for cable assembly?

You need cable ties, a wire stripper, a label maker, and a tester. These tools help you keep cables neat and working right.

How do I avoid tangled cables?

You can use Velcro straps or cable spines. Coil extra cable into loose loops. Label both ends so you always know which cable goes where.

Can I reuse cable ties?

Yes, you can reuse Velcro ties. They are easy to open and close. Plastic ties are not reusable, so choose Velcro for easy changes.