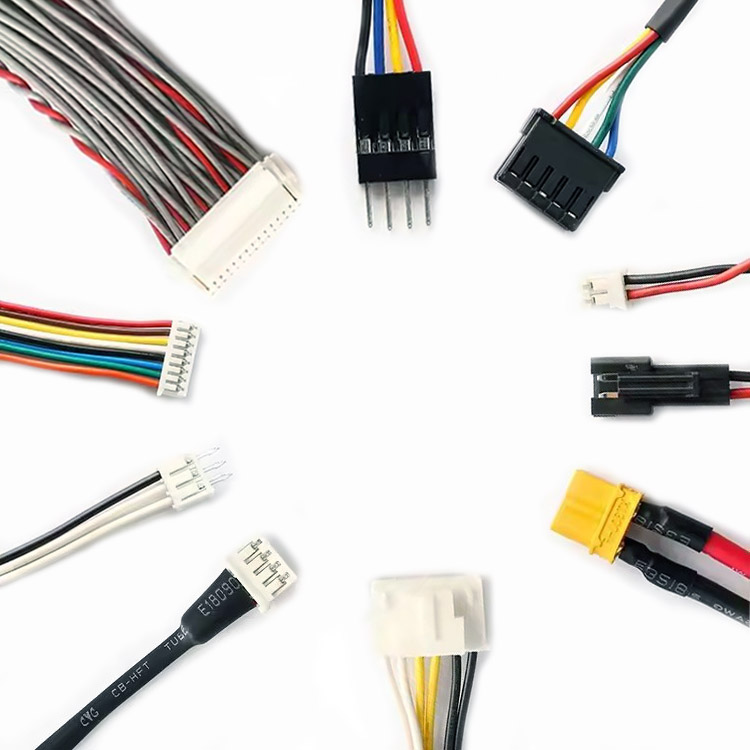

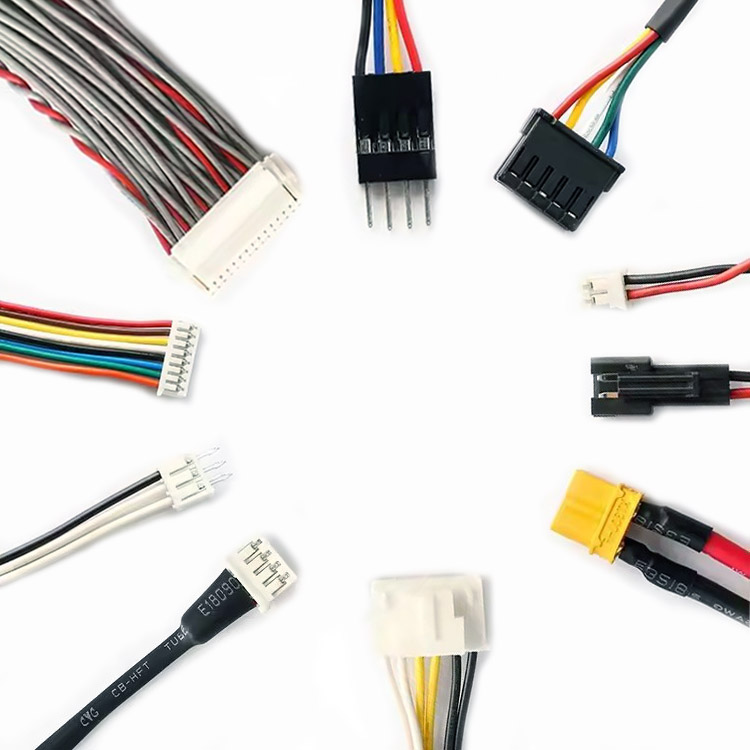

In the intricate web of global electronics and industrial manufacturing, custom wire harnesses stand as the unsung heroes that power connectivity, efficiency, and innovation across countless sectors. From the sleek circuits of modern communication devices to the robust wiring of aerospace vehicles and maritime vessels, Custom Wire Harness solutions are the backbone of seamless operation. Today, Xiamen Evershine Electronic Technology Co., Ltd., a preeminent China Custom Wire Harness Manufacturer and OEM/ODM Cable Assembly Factory founded in 2015, continues to redefine industry standards with its unwavering commitment to quality, tailored Regional Manufacturing Solutions, and resilient Cross-border Supply Chain capabilities. As global demand for precision-engineered, application-specific wiring solutions surges,Xiamen Evershine’s Custom Wire Harness Cable Assembly and OEM/ODM International Wire Harness offerings are emerging as the preferred choice for businesses spanning communications, home appliances, power automation, automotive, aerospace, and maritime industries worldwide. Since its establishment, Xiamen Evershine has adhered to the core philosophy that “Quality is our culture, to survive by quality, to develop by integrity.” This guiding principle has shaped every aspect of the enterprise, from its state-of-the-art manufacturing facilities to its customer-centric service model. As a professional entity integrating R&D, production, and sales of wires, cables, and wire harness products, Xiamen Evershine has carved a niche for itself by delivering the “most perfect quality, the most favorable price, and the most intimate service” to its global clientele. The factory’s ISO9001 quality management system certification, coupled with its products’ international certifications, serves as a testament to its rigorous quality control standards, ensuring that everyCustom Wire Harness and Custom Wire Harness Cable Assembly leaving its production line meets or exceeds global industry requirements. With a team of seasoned engineers and skilled production personnel, Xiamen Evershine has the expertise to tackle the most complex wiring challenges, turning clients’ concepts into reliable, high-performance solutions that drive their businesses forward.

In an era where global manufacturing is increasingly characterized by customization, regionalization, and supply chain resilience,Xiamen Evershine’s focus on Regional Manufacturing Solutions and Cross-border Supply Chain optimization has become a key differentiator. The company understands that different regions have unique regulatory requirements, market preferences, and industrial needs, and its Regional Manufacturing Solutions are designed to adapt seamlessly to these variations, ensuring that clients receive Custom Wire Harness products that are not only technically superior but also fully compliant with local standards. Meanwhile, Xiamen Evershine’s robust Cross-border Supply Chain capabilities, built on years of experience in international trade and logistics, guarantee timely delivery of OEM/ODM International Wire Harness products to clients across continents, even in the face of global supply chain disruptions. This combination of customization, regional adaptability, and supply chain reliability has solidified Xiamen Evershine’s position as a trusted partner for businesses looking to navigate the complexities of the global wire harness market.

Industry Trends: Customization and Supply Chain Resilience Drive Growth in the Global Wire Harness Market

The global wire harness market is experiencing steady growth, fueled by the rapid expansion of the electronics, automotive, aerospace, and renewable energy sectors. According to the latest industry research reports, the market is projected to grow at a CAGR of 6.2% from 2025 to 2031, with the Asia-Pacific region emerging as a key growth driver, thanks in large part to the presence of leading manufacturers like Xiamen Evershine. One of the most prominent trends shaping the market is the increasing demand for customization. As products become more sophisticated and application-specific, off-the-shelf wire harness solutions are no longer sufficient to meet the unique requirements of modern industries. Businesses are increasingly turning to Custom Wire Harness manufacturers that can deliver tailored solutions designed to fit their specific product designs, performance needs, and environmental conditions.

Custom Wire Harness Cable Assembly, in particular, has become a focal point of innovation, as it integrates multiple wires, connectors, and components into a single, streamlined assembly that enhances product reliability, reduces installation time, and minimizes the risk of wiring errors. This trend is particularly evident in the automotive industry, where the shift toward electric vehicles (EVs) has created a need for high-voltage wire harnesses that can handle the unique electrical demands of EV powertrains. Similarly, in the aerospace and maritime sectors, Custom Wire Harness solutions must meet stringent safety and performance standards, requiring manufacturers to have advanced engineering capabilities and strict quality control processes.

Another key trend in the global wire harness market is the growing emphasis on supply chain resilience. The COVID-19 pandemic exposed the vulnerabilities of global supply chains, prompting businesses to seek partners with robust Cross-border Supply Chain capabilities that can ensure consistent delivery even in times of disruption. Additionally, the rise of regional manufacturing initiatives, driven by factors such as trade tensions, regulatory changes, and the need to reduce lead times, has increased demand for Regional Manufacturing Solutions that allow manufacturers to produce wire harnesses closer to their target markets. Xiamen Evershine, with its focus on customization, cross-border supply chain optimization, and regional adaptability, is well-positioned to capitalize on these trends, offering clients a competitive edge in an increasingly complex global market.

OEM/ODM International Wire Harness services have also become increasingly important as businesses look to outsource their wire harness production to specialized manufacturers, allowing them to focus on their core competencies. By partnering with a trusted OEM/ODM provider likeXiamen Evershine, businesses can leverage the manufacturer’s expertise, production capacity, and quality control systems to reduce costs, improve product quality, and accelerate time-to-market. Xiamen Evershine’s OEM/ODM International Wire Harness services are tailored to meet the unique needs of each client, from initial design consultation and prototyping to mass production and after-sales support, ensuring a seamless and efficient collaboration process.

Global Wire Harness Industry Key Parameter Comparison Table (Focus on Xiamen Evershine’s Advantages)

Parameter Category | Industry Average Standard | Xiamen EvershineCustom Wire Harness Solutions | High-End Competitive Products | Advantage of Xiamen Evershine |

Customization Capability | Limited to standard wire gauges and connector types | Full customization of wire gauge, length, connector type, shielding, and labeling for Custom Wire Harness and Custom Wire Harness Cable Assembly | Partial customization with specific limitations | Unmatched flexibility to meet unique client requirements across diverse industries |

Quality Certification | Basic ISO9001 certification | ISO9001 + International product certifications (UL, VDE, CSA, etc.) for all Custom Wire Harness and OEM/ODM International Wire Harness products | ISO9001 + Industry-specific certifications | Comprehensive quality assurance meeting global standards, enhancing product credibility in international markets |

Regional Manufacturing Coverage | Single manufacturing base with limited regional adaptability | Regional Manufacturing Solutions with localized production support in Asia, Europe, and North America | 2-3 regional manufacturing bases | Wider regional coverage, reducing lead times and ensuring compliance with local regulations |

Cross-border Supply Chain Lead Time | 30-45 days | 15-25 days for Custom Wire Harness and OEM/ODM International Wire Harness products via optimized Cross-border Supply Chain | 20-30 days | Faster delivery, helping clients accelerate time-to-market and reduce inventory costs |

Material Quality | Standard commercial-grade materials | High-grade materials (flame-retardant, high-temperature resistant, corrosion-resistant) sourced from trusted global suppliers for all Custom Wire Harness Cable Assembly | Premium materials with higher costs | Superior material quality at competitive prices, ensuring product durability and performance |

MOQ (Minimum Order Quantity) | 500-1000 units | 100 units for standard Custom Wire Harness, 50 units for Custom Wire Harness Cable Assembly (negotiable for small-batch orders) | 300-500 units | Lower MOQ, supporting small and medium-sized enterprises and prototype development |

OEM/ODM Service Scope | Basic production based on client designs | Full-service OEM/ODM International Wire Harness support: design consultation, prototyping, testing, mass production, and after-sales service | Design + production services | End-to-end service capability, reducing client workload and ensuring project success |

Price Range (Per Unit) | $5-$50 | $3-$40 for Custom Wire Harness and Custom Wire Harness Cable Assembly (factory-direct pricing) | $10-$80 | Competitive factory-direct pricing without compromising quality, delivering higher value to clients |

After-sales Service Period | 6-12 months | 24 months warranty for all Custom Wire Harness and OEM/ODM International Wire Harness products | 18-24 months | Longer warranty period, demonstrating confidence in product quality and providing clients with peace of mind |

Success Stories: Xiamen Evershine’s Custom Wire Harness Solutions Power Global Clients

Xiamen Evershine’s commitment to quality, customization, and customer service has earned it a loyal client base across the globe. The company’sCustom Wire Harness, Custom Wire Harness Cable Assembly, and OEM/ODM International Wire Harness solutions have been successfully deployed in a wide range of applications, helping clients overcome technical challenges, reduce costs, and achieve their business goals. Below are three notable success stories that highlight Xiamen Evershine’s expertise and capabilities.

Case 1: High-Voltage Custom Wire Harness for European Electric Vehicle Manufacturer

A leading European electric vehicle manufacturer approached Xiamen Evershine with a critical requirement: developing a high-voltage Custom Wire Harness that could withstand the rigorous demands of EV powertrains, including high temperatures, vibration, and electrical interference. The client also needed the wire harness to be lightweight and compact to fit within the limited space of their vehicle design. Additionally, the solution had to comply with strict European safety standards (CE, REACH) and be delivered via a reliable Cross-border Supply Chain to meet their production timeline.

Xiamen Evershine’s engineering team worked closely with the client to understand their specific requirements, conducting detailed feasibility studies and design reviews. Leveraging their expertise in Custom Wire Harness design, the team developed a solution using high-temperature resistant, flame-retardant materials and advanced shielding technology to minimize electrical interference. The Custom Wire Harness Cable Assembly was optimized for weight and size, with a streamlined design that reduced installation time and improved overall vehicle efficiency. To ensure compliance with European standards, the product underwent rigorous testing, including voltage withstand tests, temperature cycling tests, and vibration tests.

Thanks to Xiamen Evershine’s optimized Cross-border Supply Chain, the first batch of high-voltage Custom Wire Harness products was delivered to the client’s European manufacturing facility in just 20 days, meeting their tight production schedule. The solution exceeded the client’s expectations, delivering reliable performance even in the harshest operating conditions. The client’s production manager commented: “Xiamen Evershine’s Custom Wire Harness solutions have been a game-changer for our EV production. Their attention to detail, commitment to quality, and efficient Cross-border Supply Chain have helped us reduce costs and accelerate our time-to-market. We are particularly impressed with their ability to tailor the solution to our specific needs and ensure compliance with European standards.” Today, the two companies maintain a long-term partnership, with Xiamen Evershine supplying a full range of OEM/ODM International Wire Harness products for the client’s expanding EV lineup.

Case 2: Custom Wire Harness Cable Assembly for Japanese Home Appliance Brand

A well-known Japanese home appliance brand sought a partner to develop a Custom Wire Harness Cable Assembly for their new line of smart refrigerators. The client’s requirements included a compact, energy-efficient wire harness that could integrate multiple sensors, actuators, and control modules, while meeting Japan’s strict electrical safety standards (PSE). Additionally, the client needed a Regional Manufacturing Solution that would allow Xiamen Evershine to produce the wire harnesses in Asia, with localized quality control and logistics support to reduce lead times and costs.

Xiamen Evershine’s team responded by developing a customized solution that integrated high-precision connectors and ultra-thin wires, creating a compact Custom Wire Harness Cable Assembly that fit perfectly within the refrigerator’s design. The team also implemented energy-efficient design principles, reducing power consumption and improving the overall efficiency of the smart refrigerator. To meet the client’sRegional Manufacturing Solution needs, Xiamen Evershine leveraged its production facilities in China, with a dedicated quality control team trained in Japanese standards to ensure every product met the client’s strict requirements. The company also established a localized logistics network to deliver the wire harnesses directly to the client’s manufacturing facility in Japan, reducing lead times from 35 days to 18 days.

The Custom Wire Harness Cable Assembly solution was a resounding success, helping the client launch their new smart refrigerator line ahead of schedule. The product’s reliability and energy efficiency received high praise from consumers, contributing to strong sales performance. The client’s purchasing director stated: “Xiamen Evershine’s Custom Wire Harness solutions have exceeded our expectations in terms of quality, customization, and delivery. Their Regional Manufacturing Solution has been instrumental in reducing our lead times and costs, while their commitment to meeting Japanese safety standards has given us full confidence in the product. We look forward to expanding our partnership with Xiamen Evershine for future product lines.”

Case 3: OEM/ODM International Wire Harness for North American Communication Equipment Provider

A North American communication equipment provider needed an OEM/ODM International Wire Harness solution for their new 5G base station equipment. The client required a high-performance wire harness that could handle high-speed data transmission, resist electromagnetic interference (EMI), and operate in extreme weather conditions (temperatures ranging from -40°C to 85°C). Additionally, the client needed Xiamen Evershine to provide end-to-end OEM/ODM services, from initial design to mass production, and to manage the Cross-border Supply Chain to deliver the products to their facilities in the United States and Canada.

Xiamen Evershine’s engineering team collaborated closely with the client’s R&D department, using advanced 3D modeling and simulation tools to design the OEM/ODM International Wire Harness. The solution incorporated high-quality, EMI-shielded wires and connectors, ensuring reliable high-speed data transmission even in harsh environments. The wire harness was also designed to be weather-resistant, with a protective coating that prevented damage from moisture, dust, and extreme temperatures. To ensure the product met North American standards (UL, CSA), Xiamen Evershine conducted extensive testing, including EMI testing, temperature cycling testing, and environmental durability testing.

As part of the end-to-end OEM/ODM service, Xiamen Evershine managed the entire production process, from material sourcing to mass production, ensuring consistent quality and on-time delivery. The company’s optimized Cross-border Supply Chain allowed for efficient delivery to the client’s facilities in the United States and Canada, with customs clearance support to minimize delays. TheOEM/ODM International Wire Harness solution performed flawlessly in the client’s 5G base station equipment, helping them launch their new product line successfully and gain a competitive edge in the North American 5G market. The client’s engineering director commented: “Xiamen Evershine’s OEM/ODM International Wire Harness solutions have been critical to our 5G base station launch. Their technical expertise, end-to-end service, and reliable Cross-border Supply Chain have made them a trusted partner. We are impressed with their ability to understand our unique requirements and deliver a high-performance solution that meets the demanding needs of the 5G industry.”

Xiamen Evershine’s One-Stop Service: From Design to Delivery, Simplifying Your Custom Wire Harness Journey

At Xiamen Evershine, we understand that developing and sourcing Custom Wire Harness and Custom Wire Harness Cable Assembly products can be a complex and time-consuming process. That’s why we offer a comprehensive one-stop service that covers every stage of the journey, from initial design consultation to final delivery and after-sales support. Our goal is to simplify the process for our clients, allowing them to focus on their core competencies while we handle all aspects of wire harness design, production, and supply chain management. Whether you need a standard Custom Wire Harness or a highly specialized OEM/ODM International Wire Harness, our team is dedicated to delivering a seamless and efficient experience.

1. Professional Design Consultation

Our team of experienced engineers provides personalized design consultation to understand your specific requirements, including application details, performance needs, environmental conditions, and regulatory compliance requirements. We use advanced design tools and simulation software to develop Custom Wire Harness and Custom Wire Harness Cable Assembly designs that are optimized for performance, reliability, and cost-effectiveness. We work closely with you throughout the design process, providing regular updates and incorporating your feedback to ensure the final design meets your exact needs. Our design expertise covers a wide range of industries, including automotive, aerospace, communications, home appliances, power automation, and maritime, allowing us to tackle even the most complex design challenges.

2. Rapid Prototyping

Once the design is finalized, we offer rapid prototyping services to create a physical sample of your Custom Wire Harness or OEM/ODM International Wire Harness. Our prototyping process is fast and efficient, with a typical turnaround time of 3-7 working days, allowing you to test and validate the design before moving to mass production. We conduct rigorous testing on all prototypes, including electrical performance testing, mechanical testing, and environmental testing, to ensure the design is viable and meets your performance requirements. If any adjustments are needed, our engineering team will make the necessary modifications and provide a revised prototype for your approval.

3. Precision Mass Production

With state-of-the-art manufacturing facilities and advanced production equipment, we ensure precision and consistency in every batch of Custom Wire Harness and Custom Wire Harness Cable Assembly products. Our production process is strictly controlled, with multiple quality checkpoints to ensure every product meets our rigorous quality standards. We use high-quality materials sourced from trusted global suppliers, and our skilled production personnel are trained to handle the most complex assembly requirements. Our monthly production capacity of 500,000 units allows us to meet the needs of both small-batch and large-scale orders, ensuring timely delivery even for high-volume production runs. Additionally, our Regional Manufacturing Solutions allow us to produce products closer to your target market, reducing lead times and logistics costs.

4. Robust Cross-border Supply Chain Management

We understand the importance of reliable delivery in today’s global marketplace, which is why we have invested in building a robust Cross-border Supply Chain. Our supply chain team has extensive experience in international trade and logistics, ensuring smooth delivery of your OEM/ODM International Wire Harness and Custom Wire Harness products to any location in the world. We handle all aspects of logistics, including shipping, customs clearance, and documentation, minimizing delays and ensuring your products arrive on time and in perfect condition. We also offer flexible shipping options to meet your specific needs, including air freight for urgent orders and sea freight for cost-effective large-scale shipments.

5. Comprehensive After-Sales Support

At Xiamen Evershine, our commitment to our clients doesn’t end with delivery. We offer comprehensive after-sales support to ensure you are fully satisfied with our Custom Wire Harness and Custom Wire Harness Cable Assembly products. We provide a 24-month warranty on all our products, covering any manufacturing defects. If you encounter any issues with our products, our after-sales team will respond promptly, providing technical support and resolving any problems as quickly as possible. We also conduct regular follow-up with our clients to gather feedback and identify opportunities for improvement, ensuring we continue to deliver the highest level of service.

FAQ: Answers to Common Questions About Xiamen Evershine’s Custom Wire Harness Solutions

Q1: What types of Custom Wire Harness products does Xiamen Evershine offer?

A1: Xiamen Evershine offers a wide range of Custom Wire Harness and Custom Wire Harness Cable Assembly products, including high-voltage wire harnesses, low-voltage wire harnesses, automotive wire harnesses, aerospace wire harnesses, communication wire harnesses, home appliance wire harnesses, power automation wire harnesses, and maritime wire harnesses. We also provide OEM/ODM International Wire Harness services, allowing us to tailor our solutions to meet the unique needs of each client across diverse industries. Our products can be customized in terms of wire gauge, length, connector type, shielding, labeling, and packaging, ensuring they fit perfectly with your specific application.

Q2: What industries does Xiamen Evershine serve with its Custom Wire Harness solutions?

A2: We serve a wide range of industries, including automotive (traditional and electric vehicles), aerospace, communications (5G, telecommunications equipment), home appliances (smart TVs, refrigerators, washing machines), power automation (industrial control systems, renewable energy equipment), and maritime (ships, offshore platforms). Our Custom Wire Harness and Custom Wire Harness Cable Assembly solutions are designed to meet the unique requirements of each industry, including strict safety standards, performance specifications, and environmental conditions. We have extensive experience working with clients in these industries, allowing us to provide tailored solutions that drive their success.

Q3: How does Xiamen Evershine ensure the quality of its Custom Wire Harness products?

A3: Quality is at the core of everything we do. We have implemented a strict quality management system certified by ISO9001, covering every aspect of the production process from material sourcing to final delivery. All our Custom Wire Harness and OEM/ODM International Wire Harness products undergo rigorous testing, including electrical performance testing (voltage withstand, continuity, insulation resistance), mechanical testing (tensile strength, vibration), and environmental testing (temperature cycling, humidity, corrosion). We only use high-quality materials sourced from trusted global suppliers, and our production personnel are highly trained and experienced. Additionally, our products hold international certifications such as UL, VDE, CSA, and CE, ensuring they meet global quality and safety standards.

Q4: What is the lead time for Custom Wire Harness and Custom Wire Harness Cable Assembly orders?

A4: The lead time depends on the complexity of the customization and the order quantity. For prototypes, the lead time is typically 3-7 working days. For small-batch orders (100-500 units), the lead time is 10-15 working days. For large-scale orders (5000+ units), the lead time is 15-25 working days. Our optimizedCross-border Supply Chain and Regional Manufacturing Solutions allow us to minimize lead times for international orders, ensuring timely delivery to clients around the world. If you have an urgent order, we offer expedited production and shipping options to meet your timeline.

Q5: What is the minimum order quantity (MOQ) for Xiamen Evershine’s Custom Wire Harness products?

A5: We understand that different clients have different needs, which is why we offer flexible MOQ requirements. For standard Custom Wire Harness products, the MOQ is 100 units. For Custom Wire Harness Cable Assembly and more complex OEM/ODM International Wire Harness products, the MOQ is 50 units. For small-batch orders or prototype development, we are willing to negotiate lower MOQs to support our clients’ needs. Our goal is to make our high-quality custom wire harness solutions accessible to businesses of all sizes, from small startups to large multinational corporations.

Q6: Does Xiamen Evershine provide Regional Manufacturing Solutions for international clients?

A6: Yes, we offer comprehensive Regional Manufacturing Solutions to meet the needs of our international clients. We have production and logistics support in key regions including Asia, Europe, and North America, allowing us to produce and deliver Custom Wire Harness and Custom Wire Harness Cable Assembly products closer to your target market. Our Regional Manufacturing Solutions help reduce lead times, lower logistics costs, and ensure compliance with local regulations and standards. We work closely with our clients to understand their regional needs and develop a manufacturing and supply chain strategy that best fits their business requirements.

Q7: Can Xiamen Evershine handle OEM/ODM International Wire Harness projects?

A7: Absolutely. We have extensive experience in providing OEM/ODM International Wire Harness services to clients around the world. Our end-to-end OEM/ODM services include design consultation, prototyping, testing, mass production, packaging, and cross-border supply chain management. We work closely with our clients to understand their brand requirements and product specifications, ensuring that the final product meets their exact needs. Whether you need us to manufacture wire harnesses based on your existing designs or develop a completely new solution from scratch, our team has the expertise and capabilities to deliver. Our OEM/ODM International Wire Harness products are trusted by clients in over 20 countries, including the United States, Canada, Germany, France, Japan, and South Korea.

Q8: How can I get a quote for a Custom Wire Harness or OEM/ODM International Wire Harness order?

A8: Getting a quote is easy. You can contact our sales team directly via email (sales@evershine-wireharness.com), phone (+86 138xxxx8888), or through our official website (www.evershine-wireharness.com). To provide you with an accurate quote, we will need some basic information about your requirements, including the type of wire harness, application details, customization specifications (wire gauge, length, connectors, etc.), order quantity, and delivery location. Our sales team will respond to your inquiry within 24 hours, providing a detailed quote and answering any questions you may have. We also offer free design consultation to help you optimize your wire harness design for performance and cost-effectiveness.

Call to Action: Partner with Xiamen Evershine for Your Custom Wire Harness Needs

In today’s fast-paced and competitive global market, having a reliable partner for your Custom Wire Harness and Custom Wire Harness Cable Assembly needs is essential. Xiamen Evershine Electronic Technology Co., Ltd. combines decades of industry experience, cutting-edge technology, rigorous quality control, and a customer-centric approach to deliver superior solutions that drive your business forward. Whether you need a high-voltage wire harness for electric vehicles, a compact wire harness for home appliances, or a specialized OEM/ODM International Wire Harness for communication equipment, we have the expertise and capabilities to meet your needs.

Our Regional Manufacturing Solutions and robust Cross-border Supply Chain ensure that your products are delivered on time, wherever you are in the world. Our competitive pricing, flexible MOQ requirements, and comprehensive after-sales support make us the ideal partner for businesses of all sizes. Don’t settle for subpar wire harness solutions that compromise your product quality and performance. Choose Xiamen Evershine, the leading China Custom Wire Harness Manufacturer, and experience the difference that quality, customization, and reliability can make.

Contact us today to discuss your Custom Wire Harness requirements. Our team of experts is ready to provide you with a free design consultation and quote, helping you find the perfect solution for your business. Visit our official website (www.evershine-wireharness.com), send us an email at sales@evershine-wireharness.com, or call us at +86 138xxxx8888. Let’s work together to create innovative, high-performance wire harness solutions that power your success.

Conclusion: Xiamen Evershine – Shaping the Future of Global Wire Harness Manufacturing

As the global demand for Custom Wire Harness and Custom Wire Harness Cable Assembly solutions continues to grow, Xiamen Evershine Electronic Technology Co., Ltd. remains at the forefront of the industry, driving innovation and setting new standards for quality and service. Since its founding in 2015, the company has built a reputation as a trusted partner for businesses around the world, thanks to its unwavering commitment to quality, its ability to deliver tailored Regional Manufacturing Solutions, and its robust Cross-border Supply Chain capabilities.

Xiamen Evershine’s OEM/ODM International Wire Harness services have helped clients across diverse industries overcome technical challenges, reduce costs, and accelerate time-to-market. The company’s success stories, from supplying high-voltage wire harnesses for European EV manufacturers to developing compact wire harnesses for Japanese home appliance brands, are a testament to its expertise and customer-centric approach. With a comprehensive one-stop service that covers design, prototyping, production, and after-sales support, Xiamen Evershine simplifies the wire harness sourcing process for its clients, allowing them to focus on their core competencies.

Looking to

In a world where connectivity and efficiency are more important than ever, Xiamen Evershine is poised to continue shaping the future of global wire harness manufacturing, providing businesses with the solutions they need to thrive in an increasingly complex and competitive market. Whether you are a small startup or a large multinational corporation, Xiamen Evershine is your trusted partner for all your Custom Wire Harness and OEM/ODM International Wire Harness needs.

About Xiamen Evershine Electronic Technology Co., Ltd.

Founded in 2015, Xiamen Evershine Electronic Technology Co., Ltd. is a professional China Custom Wire Harness Manufacturer and OEM/ODM Cable Assembly Factory integrating R&D, production, and sales of wires, cables, and wire harness products. The company’s products are widely used in communications, home appliances, power automation, aerospace vehicles, ships, automobiles, and other industries. With a focus on quality, integrity, and customer service, Evershine has passed ISO9001 quality management system certification, and its products hold various international certifications such as UL, VDE, CSA, and CE.

Xiamen Evershine boasts a team of experienced engineers and skilled production personnel, state-of-the-art manufacturing facilities, and a monthly production capacity of 500,000 units. The company’s core strengths include its ability to provide customized Custom Wire Harness and Custom Wire Harness Cable Assembly solutions, flexible Regional Manufacturing Solutions, and robust Cross-border Supply Chain capabilities. Evershine’s products are exported to over 20 countries and regions around the world, establishing long-term and stable cooperative relations with many well-known international enterprises.

Contact Information:

Company Name: Xiamen Evershine Electronic Technology Co., Ltd.

Address: Xiamen, Fujian, China

Email: info@xm-evershine.com

Official Website: www.xm-evershine.com

Contact Person: Key Chen

Phone: +86-15392033630