A New Paradigm for China’s Global Expansion: How Custom Wire Harness Localization Is Redefining International Manufacturing Services

2025-12-10 10:46As global manufacturing enters a new phase marked by geopolitical uncertainty, rising compliance requirements, and increasingly complex customer demands, the traditional export model of “produce in China, ship worldwide” is no longer sufficient. For many Chinese manufacturers, especially in the wire harness sector, a new paradigm is emerging—one that emphasizes local responsiveness, regional integration, and service proximity.

This shift has given rise to Global Localization Wire Harness strategies that blend centralized engineering with distributed service capabilities. Rather than competing solely on cost, leading Chinese manufacturers are now competing on speed, adaptability, and trust, redefining how global customers engage with overseas suppliers.

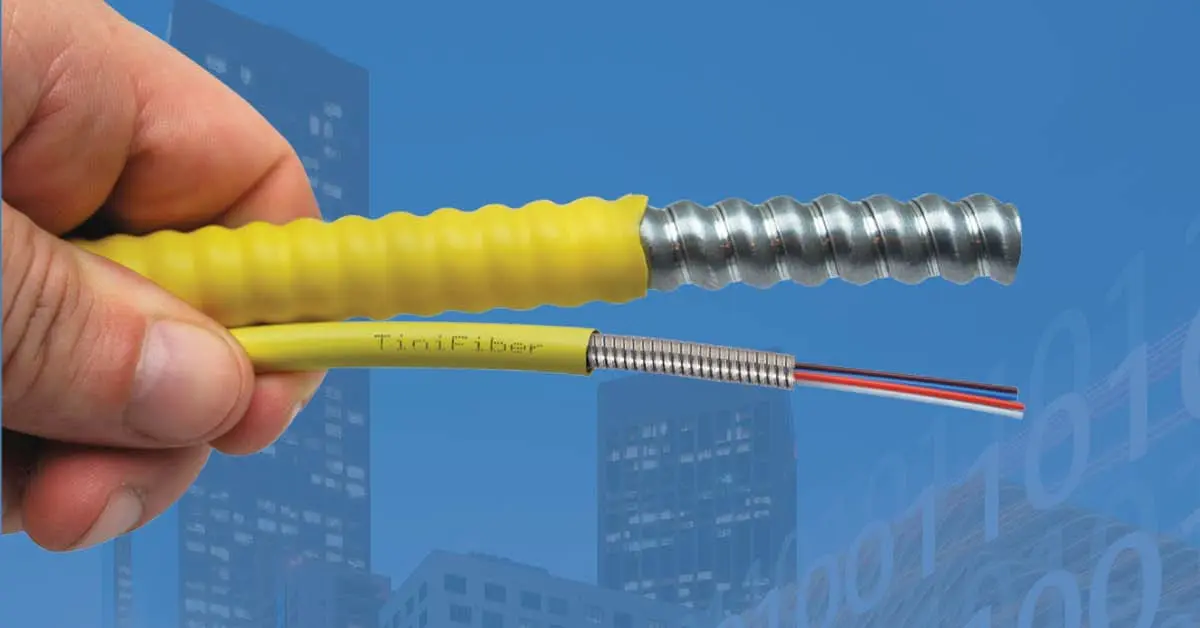

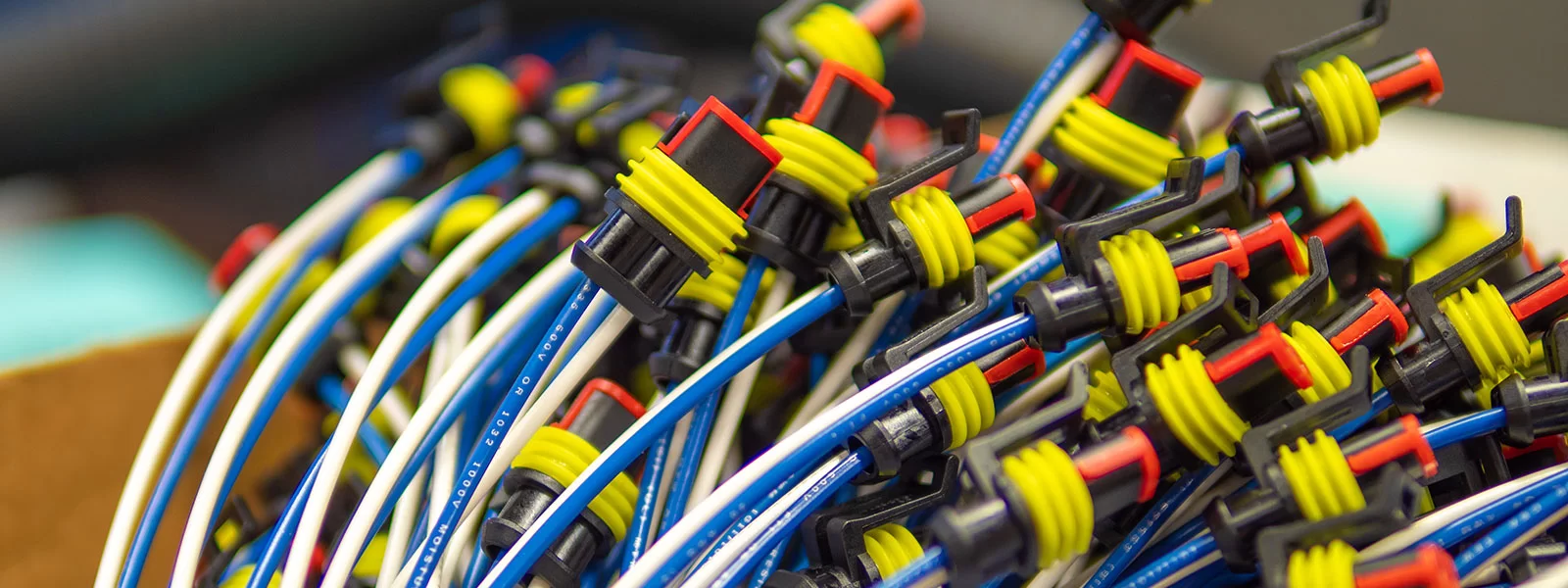

Founded in 2015, Xiamen Evershine Electronic Technology Co., Ltd. exemplifies this transformation. Specializing in wire, cable, and wire harness R&D, production, and sales, Evershine serves industries ranging from communications and home appliances to power automation, aerospace, marine, and automotive applications. With ISO9001 certification and multiple international approvals, the company has built a quality system designed for global collaboration rather than one-way export.

From Exporter to Partner: Why Localization Matters Now

In the past, wire harness sourcing decisions were driven primarily by price and production capacity. Today, global OEMs and system integrators are placing equal weight on delivery reliability, regulatory compliance, and engineering support across regions.

This has accelerated demand for Worldwide Cable Assembly Service models, where suppliers are expected to provide synchronized support across time zones and markets. Under this approach, China remains the engineering and manufacturing backbone, while customer-facing processes are adapted locally.

At the same time, Cross-border Supply Chain resilience has become a strategic priority. Manufacturers capable of balancing centralized efficiency with localized responsiveness are gaining a decisive advantage.

Industry Perspective: Key Indicators Driving Localization Strategies

| Indicator | 2024 Status | 2027 Outlook | Strategic Impact |

| Global OEM localization demand | Medium | High | Faster response required |

| Lead time tolerance | 20–30 days | 7–14 days | Service proximity critical |

| Compliance complexity | Growing | High | Local expertise needed |

| Multi-region sourcing | Optional | Standard | Risk diversification |

| Supplier collaboration depth | Transactional | Strategic | Long-term partnerships |

These trends explain why Regional Manufacturing Solutions are no longer optional extensions, but core components of competitive positioning.

How Chinese Manufacturers Are Executing Global Localization

The transition toward localization is not about building factories everywhere. Instead, it is about redesigning service architecture. Leading manufacturers focus on three execution pillars:

Centralized Engineering, Localized Interfaces

Core design and process control remain centralized, while customer communication, documentation, and technical support are adapted locally—enabling effective Worldwide Cable Assembly Service without duplicating resources.Flexible Production and Logistics Networks

By integrating logistics planning into product design, suppliers improve Cross-border Supply Chain efficiency and mitigate regional disruptions.Compliance and Customization at the Regional Level

Tailored certifications and application-specific adaptations form the backbone of practical Regional Manufacturing Solutions.

Through this model, Chinese suppliers evolve into true International Wire Harness Supplier partners rather than distant vendors.

Evershine’s Localization-Oriented Service Model

Xiamen Evershine Electronic Technology Co., Ltd. has aligned its internal systems to support Global Localization Wire Harness deployment. From early-stage engineering coordination to post-delivery quality tracking, the company emphasizes consistency across regions while respecting local requirements.

Its approach allows overseas customers to benefit from China’s manufacturing efficiency while enjoying the responsiveness typically associated with local suppliers. This balance is increasingly valued by global clients navigating complex Cross-border Supply Chain environments.

FAQ: Key Questions from Global Buyers

Q1: Does localization mean higher costs?

Not necessarily. Regional Manufacturing Solutions often reduce total cost by lowering logistics risk and rework.

Q2: Can Chinese suppliers support local standards effectively?

Yes. Experienced International Wire Harness Supplier partners design compliance into the process.

Q3: How does localization improve lead times?

With Worldwide Cable Assembly Service, decision-making and communication cycles are significantly shorter.

Q4: Is this model suitable for small and medium volumes?

Absolutely. Localization is especially valuable for customized and mid-volume projects.

Q5: What should buyers look for in a localization-capable supplier?

Strong engineering depth, proven Cross-border Supply Chain coordination, and stable quality systems.

Redefining “Made in China” for the Global Market

China’s manufacturing sector is no longer defined solely by scale. Its future lies in service integration, engineering collaboration, and global alignment. The wire harness industry, once viewed as purely execution-focused, is now at the forefront of this evolution.

By combining technical expertise with Global Localization Wire Harness strategies, companies like Evershine are reshaping how international customers perceive Chinese manufacturing partners.

Conclusion and Call to Action: Building Global Value Through Local Understanding

Global expansion today requires more than shipping products overseas—it requires understanding markets, aligning processes, and responding locally while operating globally.

The new era of Worldwide Cable Assembly Service is about partnership, not distance. Choosing suppliers with proven Regional Manufacturing Solutions capabilities means choosing reliability, agility, and long-term value.

Xiamen Evershine Electronic Technology Co., Ltd. remains committed to quality, integrity, and customer-centric service—standing as a trusted International Wire Harness Supplier in an increasingly interconnected global manufacturing landscape.