2025 Breakthroughs in AI and HPC High-Speed Cable Assemblies: How 448G PAM4 and Low-Profile Design Support NVIDIA GB200 Compute Demands

2025-12-31 10:42The rapid evolution of artificial intelligence and high-performance computing is redefining the physical limits of data transmission inside next-generation servers. As platforms such as NVIDIA’s GB200 push compute density, bandwidth, and power efficiency to unprecedented levels, the supporting interconnect infrastructure must evolve just as quickly. At the center of this transformation are advanced cable architectures, signal integrity innovations, and mechanical designs optimized for extreme environments.

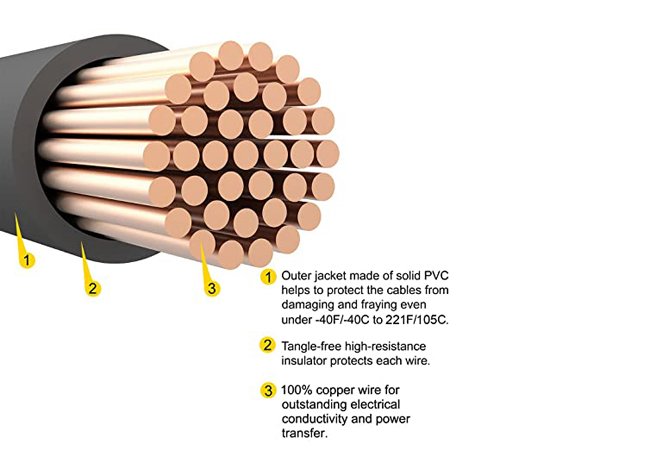

In this context, the modern Wire Harness is no longer a passive component. It has become a critical enabler of system performance, reliability, and scalability in AI and HPC architectures.

Founded in 2015, Xiamen Evershine Electronic Technology Co., Ltd. has steadily expanded its expertise in wire, cable, and harness R&D, manufacturing, and global supply. Serving industries ranging from communications and power automation to aerospace, automotive, and advanced computing, the company combines ISO9001-certified quality systems with international compliance standards. This foundation allows Evershine to respond effectively to emerging demands in high-speed computing infrastructure.

The Shift to 448G: Why Bandwidth Is Redefining Cable Assembly Design

The transition from 400G to 448G cable assembly architectures marks a pivotal moment for AI server interconnects. Driven by PAM4 modulation and parallel lane aggregation, these assemblies are designed to move massive data volumes with minimal latency and signal loss.

However, raw bandwidth alone is insufficient. To meet real-world deployment requirements, PAM4 high-speed data transmission must be paired with precise impedance control, advanced shielding, and optimized connector interfaces. Any deviation can result in eye closure, increased bit error rates, or thermal instability.

As a result, AI server wiring has become a multidisciplinary challenge, combining RF engineering, mechanical design, and thermal management into a single integrated solution.

Low-Profile Design: Solving Density and Airflow Constraints

One of the most critical mechanical innovations supporting GB200 platforms is the low - profile cable - to - board configuration. As server boards become denser and airflow paths narrower, traditional vertical connectors and bulky harness routes are no longer viable.

Low-profile architectures reduce Z-height, improve airflow efficiency, and enable tighter board stacking without compromising electrical performance. When combined with optimized Wire Harness routing, these designs support higher compute density while maintaining serviceability.

For manufacturers, this means tighter tolerances, more complex assembly processes, and greater emphasis on consistency—areas where mature production systems provide a clear advantage.

Industry Analysis: Key Parameters for AI/HPC High-Speed Cable Assemblies

| Parameter | Current Generation | 2025 Target | Impact |

| Data rate per link | 400G | 448G | Higher AI throughput |

| Modulation scheme | PAM4 | PAM4 (enhanced) | Improved spectral efficiency |

| Connector profile height | 6–8 mm | ≤4 mm | Better airflow |

| Signal loss budget | Moderate | Ultra-low | Higher stability |

| Assembly complexity | High | Very High | Increased precision required |

These parameters illustrate why 448G cable assembly development is not incremental, but transformational—especially when deployed at scale in AI clusters.

Manufacturing Execution: Turning Design into Deployment

Supporting next-generation platforms requires more than design expertise. It demands manufacturing systems capable of delivering repeatable quality under extreme specifications.

At Evershine, production processes are structured to support advanced AI server wiring needs, including controlled impedance assemblies, precision termination, and full traceability. This capability ensures that PAM4 high-speed data performance is preserved from design validation through mass deployment.

Equally important is mechanical reliability. Every low - profile cable - to - board solution must withstand vibration, thermal cycling, and long-term operational stress without degradation.

FAQ: Common Questions from AI Infrastructure Integrators

Q1: Why is 448G becoming essential for AI servers?

Higher bandwidth per link reduces interconnect congestion and improves GPU-to-GPU communication efficiency.

Q2: Does PAM4 increase system risk?

When properly engineered, PAM4 high-speed data delivers higher throughput with manageable signal integrity challenges.

Q3: Are low-profile designs harder to maintain?

Modern low - profile cable - to - board designs balance accessibility with density, supporting both performance and serviceability.

Q4: How critical is cable quality in AI clusters?

Extremely critical. A single unstable Wire Harness can affect overall cluster reliability.

Q5: Can manufacturers scale these solutions reliably?

With mature quality systems, AI server wiring can be scaled without sacrificing consistency.

China’s Evolving Role in AI Interconnect Manufacturing

China’s manufacturing ecosystem is moving beyond volume production toward high-precision, high-complexity systems. In the AI and HPC domain, this evolution is particularly visible in advanced Wire Harness and interconnect solutions.

Companies like Xiamen Evershine Electronic Technology Co., Ltd. are leveraging engineering depth, process discipline, and global compliance to support cutting-edge platforms that demand flawless 448G cable assembly execution.

Conclusion and Call to Action: Connecting the Future of AI Compute

As AI models grow larger and infrastructure more complex, performance bottlenecks increasingly shift from processors to interconnects. High-speed cables are no longer secondary components—they are foundational to system success.

The convergence of PAM4 high-speed data, compact mechanical design, and precision manufacturing defines the next phase of AI infrastructure. Choosing partners who understand the full system implications of AI server wiring is now a strategic decision.

Xiamen Evershine Electronic Technology Co., Ltd. remains committed to quality, integrity, and technical excellence—delivering advanced Wire Harness solutions that support the computing power shaping tomorrow’s AI landscape.