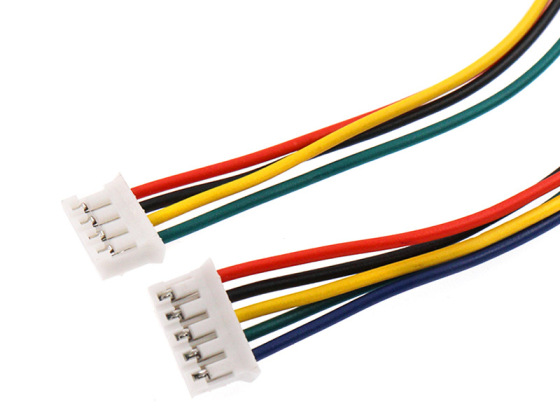

Customized Copper Wire PVC Insulated Fork Terminal Single Core Cable Assembly

Wiring Harness Factory Customized Pure Copper PVC Insulated Single Core Fork Terminal Wire Grounding Harness. This high-quality harness features a Fork design with one end tin-plated for enhanced conductivity and corrosion resistance. Crafted from pure copper and encased in durable PVC insulation, it ensures reliable grounding and a secure connection. Ideal for various industrial and automotive applications, our grounding harness is the epitome of safety and performance in a compact form.

- Evershine

- Xiamen

- 7~15 days

- 100000pcs/month

- Information

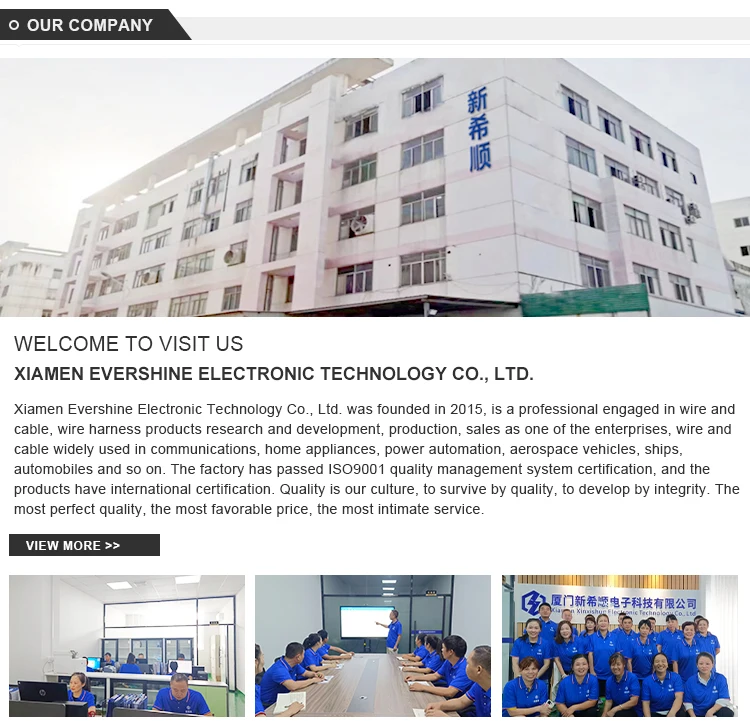

Company Information

Xiamen Evershine Electronic Technology Co., Ltd. was founded in 2015, is a professional engaged in wire and cable, wire harness products research and development, production, sales as one of the enterprises, wire and cable widely used in communications, home appliances, power automation, aerospace vehicles, ships, automobiles and so on. The factory has passed ISO9001 quality management system certification, and the products have international certification. Quality is our culture, to survive by quality, to develop by integrity. The most perfect quality, the most favorable price, the most intimate service.Now we mainly offer you the wires products list as various electronic wire harness wiring design, custom vehicle wiring harness, home appliance wire harness, customized industrial wire harness, computer wire harness, A wire harness, often referred to as a cable harness or wiring assembly, is a systematic and integrated arrangement of cables within an insulated material. The purpose of the assembly is to transmit signal or electrical power.Wire harness applications are used in nearly every conceivable household, commercial or industrial device - tools, equipment, machinery, hardware, household products - that transmits or relays electronic information or electrical power.Wire harnesses and cable assemblies are standard terms in the wire and cable industry and are used to power many different electrical devices. They are used so frequently that electrical contractors, electrical distributors, and manufacturers will often refer to them interchangeably.

over-molded cable connectors, terminal block connectors, power cable types, Products have been widely used in office equipment, communications, household appliances, industrial automation, automobile, etc.

What are the terminals in a wiring harness?

Terminals are used in wire harnesses to cease the conductor to a particular point, and secure and protect the connection. Generally made of metal or alloy, these devices may also be composed of silicon or carbon, depending upon the application requirement.

Why Are Wire Harnesses Assembled Manually?

Wire harness assembly process is one of the few remaining manufacturing processes that is more efficiently done by hand, rather than automation.This is due to the variety of processes that are involved in the assembly. These manual processes include:Installing terminated wires in various lengths Routing wires and cables through sleeves andconduits,Taping breakouts,Conducting multiple crimps.Binding the components with tape, clamps or cable ties because of the difficulty involved in automating these processes, manual production continues to be more cost-effective, especially with small batch sizes.This is also why harness production takes longer than other types of cable assemblies. Production can take anywhere from a few days to several weeks. The more complicated the design, the longer production time is required.

While it's possible to protect your wiring harness from the elements using electrical tape, silicone, or even heat shrink ,

creating a custom-made waterproof wiring harness is the only way you will know for sure that it is protected.

Waterproof Automotive Electrical Connectors Electrical Wire Connectors Plug Kit multi Pin Waterproof Connectors with Ratchet Crimping Tool.

What are wiring harnesses made of?

The electric wires or cables are bound together with the help of durable materials like zip ties , Vinyl, rubber, electric tape, string, or a combination of any of these. Wiring harnesses can be likened to a nerve system.

What is wiring harness diagram?

A wire harness is a specially designed system that keeps numerous wires or cables organized. It is a systematic and integrated arrangement of cables within an insulating material. The purpose of the wiring assembly is to transmit a signal or electrical power.

What You’d Probably Ask

If I were you, here’s what I’d want to know about cable assemblies:

1.What are the main components of a cable assembly?

A cable assembly typically consists of multiple wires or cables bundled together, connectors at one or both ends, and protective insulation or shielding. The wires transmit electrical signals or power, while the connectors ensure secure and reliable connections to devices. Insulation protects against electrical interference, moisture, and mechanical damage. Depending on the application, additional elements like strain reliefs or heat shrink tubing may be included to enhance durability and flexibility. Together, these components form a ready-to-use interconnection solution tailored to specific technical requirements.

2.How do cable assemblies improve system reliability?

Cable assemblies improve system reliability by providing pre-tested, factory-assembled wiring solutions that reduce installation errors and connection failures. The integrated connectors and shielding protect against electromagnetic interference (EMI), moisture, and mechanical stress. Quality control during manufacturing ensures consistent performance, while proper strain relief prevents cable damage from bending or pulling. This reduces downtime and maintenance costs, especially in critical applications like aerospace or automotive industries, where reliability is paramount.

3.What industries commonly use cable assemblies?

Cable assemblies are essential in industries such as automotive, aerospace, telecommunications, medical devices, consumer electronics, and industrial automation. In automotive, they connect sensors and control units; aerospace uses them for avionics systems; telecommunications rely on them for data transmission; medical devices need precise and reliable connections; consumer electronics use compact assemblies for devices; and industrial automation demands robust assemblies for machinery control. Each industry requires specific standards and customization to meet environmental and functional needs.

4. What materials are commonly used in cable assemblies?

Materials in cable assemblies include copper or aluminum conductors for efficient electrical transmission, with insulation made from PVC, Teflon, silicone, or polyethylene to provide flexibility and protection. Shielding materials like braided copper, aluminum foil, or conductive polymers protect against EMI. Connector housings are often made from plastic or metal, chosen for durability and environmental resistance. The choice of materials depends on the application’s temperature range, mechanical stress, and regulatory requirements.

5. How does shielding work in cable assemblies?

Shielding in cable assemblies involves surrounding the conductors with conductive materials such as braided copper, aluminum foil, or metalized films. This layer blocks external electromagnetic interference (EMI) from disrupting the signal and prevents signal leakage that could affect other electronics. Shielding improves signal integrity, especially in high-frequency or sensitive data transmission applications. Proper grounding of the shield is essential to maximize its effectiveness and reduce noise.

6. What role do connectors play in cable assemblies?

Connectors are critical components that enable secure, detachable connections between cable assemblies and devices. They ensure proper electrical contact, mechanical stability, and environmental protection. Different types of connectors—such as USB, HDMI, circular, or rectangular—are selected based on the application’s electrical, mechanical, and environmental requirements. High-quality connectors improve signal transmission, reduce wear and tear, and facilitate easy installation and maintenance.

7. How are cable assemblies customized for specific applications?

Customization of cable assemblies involves selecting cable length, conductor type, insulation, shielding, connector type, and additional features like strain relief or labeling. This tailoring ensures compatibility with the target device and operating environment. For example, automotive assemblies may require heat-resistant materials and vibration-resistant connectors, while medical assemblies prioritize biocompatibility and sterilization capability. Customization improves performance, safety, and ease of integration.

8. What testing methods ensure cable assembly quality?

Quality testing for cable assemblies includes continuity tests to verify electrical connections, insulation resistance tests to detect leakage, and high-voltage testing for dielectric strength. Environmental tests simulate temperature extremes, humidity, vibration, and mechanical stress to ensure durability. Signal integrity tests measure attenuation and crosstalk in data cables. Visual inspections check for manufacturing defects. These tests ensure assemblies meet industry standards and perform reliably in real-world conditions.

9. What are the benefits of modular cable assemblies?

Modular cable assemblies feature interchangeable connectors and standardized cable segments, allowing easy upgrades, repairs, or reconfiguration without replacing the entire assembly. This flexibility reduces downtime and inventory costs, particularly in complex systems like data centers or industrial machinery. Modular designs simplify installation and troubleshooting, support scalability, and enhance adaptability to evolving technological requirements.

10. How is automation impacting cable assembly manufacturing?

Automation in cable assembly manufacturing improves precision, consistency, and production speed. Automated machines handle wire cutting, stripping, crimping, and connector insertion with minimal human intervention, reducing errors and labor costs. Robotics and vision systems enhance quality control by detecting defects early. Automation also enables scalable production of complex assemblies with tight tolerances, meeting increasing demand in industries like automotive and telecommunications while maintaining high quality.