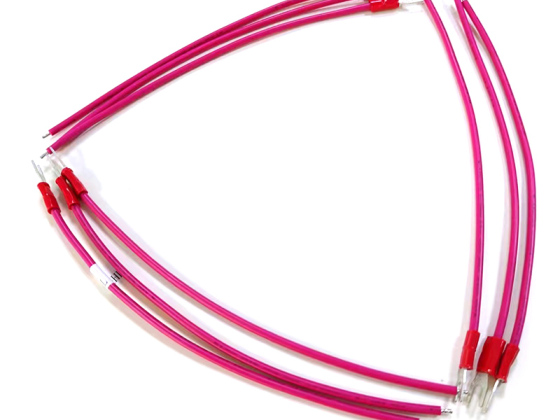

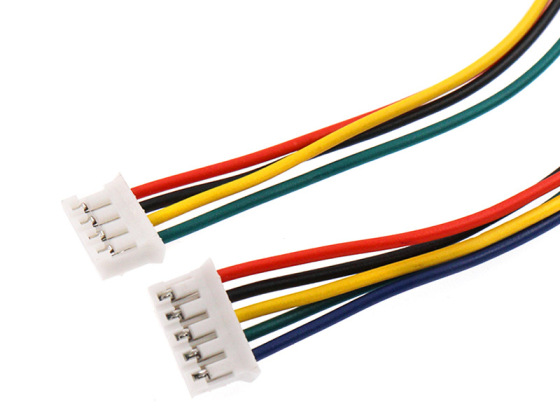

Chinese Factory DuPont SYP 2pin Connector Wire Harness

Our customized SYP DuPont electronic connection wire harnesses are expertly crafted with AC 2 pin cold pressed JST terminals, featuring a distinctive red color for easy identification. These high-quality wire harnesses are designed for reliable and secure connections in various electronic applications, ensuring durability and performance. Tailored to meet specific requirements, our solutions are perfect for a range of devices and systems.

- Evershine

- Xiamen

- 7~15 days

- 100000pcs/month

- Information

Straight Answers to Your Key Questions About wire-harness manufacturer

1. The Role of a Wire Harness Manufacturer in Various Industries

A wire harness manufacturer plays a crucial role in a vast array of industries, acting as a vital link in the supply chain. These manufacturers specialize in designing, engineering, and producing custom wire and cable harnesses tailored to the specific needs of diverse applications. In the automotive industry, they provide harnesses for everything from basic vehicle wiring to complex systems like anti-lock brakes and infotainment. The aerospace sector relies on them for high-reliability harnesses used in avionics, flight controls, and cabin systems. In the medical field, they manufacture harnesses for diagnostic equipment, patient monitoring devices, and surgical instruments, often requiring stringent cleanliness and biocompatibility standards. Industrial automation utilizes wire harnesses for connecting sensors, actuators, and control systems in manufacturing machinery. Even consumer electronics, like appliances and entertainment systems, depend on these manufacturers for organized and reliable wiring solutions. Essentially, any industry that relies on electrical or electronic systems utilizes the expertise and capabilities of a wire harness manufacturer to ensure efficient, safe, and reliable operation.

2. Key Capabilities and Services Offered by Wire Harness Manufacturers

Wire harness manufacturers offer a comprehensive suite of services to meet the diverse needs of their clients. These capabilities extend beyond just manufacturing and often include design and engineering support, prototyping, testing, and supply chain management. Design services involve collaborating with clients to develop custom harness designs that meet specific performance, size, and environmental requirements. Prototyping allows for the creation of sample harnesses for testing and validation before mass production. Manufacturing capabilities encompass wire cutting, stripping, crimping, soldering, overmolding, and assembly, utilizing both automated and manual processes. Testing services ensure that harnesses meet industry standards and customer specifications, including continuity testing, insulation resistance testing, and pull-force testing. Many manufacturers also offer supply chain management services, sourcing components, managing inventory, and providing just-in-time delivery to streamline their clients' operations. The breadth of these capabilities enables wire harness manufacturers to act as strategic partners, providing comprehensive solutions from concept to delivery.

3. The Design and Engineering Process at a Wire Harness Manufacturing Company

The design and engineering process at a wire harness manufacturing company is a critical phase that determines the final product's functionality, reliability, and cost-effectiveness. It begins with a thorough understanding of the client's requirements, including electrical specifications, environmental conditions, space constraints, and regulatory compliance. Engineers then create detailed harness designs using CAD software, specifying wire gauges, connector types, routing paths, and protective coverings. Simulation tools may be used to analyze voltage drop, signal integrity, and thermal performance. Design for Manufacturability (DFM) principles are applied to optimize the harness for efficient and cost-effective production. Prototyping is used to create sample harnesses for testing and validation. Once the design is finalized, detailed manufacturing instructions are generated, including wire cutting lists, crimping specifications, and assembly procedures. The design and engineering process is iterative, with continuous refinement based on testing results and feedback from the manufacturing team. This ensures that the final wire harness meets all performance and quality requirements.

4. Quality Control and Testing Procedures in Wire Harness Manufacturing

Quality control and testing are paramount in wire harness manufacturing to ensure reliability and safety. Manufacturers implement rigorous procedures throughout the production process to identify and address any potential defects. Incoming materials are inspected for compliance with specifications, and in-process inspections are conducted at each stage of manufacturing, from wire cutting to connector attachment. Continuity testing verifies that all wires are properly connected and that there are no open circuits. Insulation resistance testing measures the resistance between wires and ground to detect any insulation failures. High-voltage testing applies a high voltage to the harness to verify its dielectric strength. Pull-force testing measures the force required to pull a wire out of a connector to ensure proper crimping. Environmental testing simulates extreme temperatures, humidity, and vibration to assess the harness’s durability. Automated testing equipment is used to perform comprehensive electrical tests and generate detailed reports. Statistical process control (SPC) is used to monitor and control the manufacturing process and identify any potential quality issues. This comprehensive approach ensures that only high-quality wire harnesses are shipped to customers.

5. The Importance of Certifications and Standards for Wire Harness Manufacturers

Certifications and standards play a vital role in the wire harness manufacturing industry, ensuring product quality, safety, and regulatory compliance. ISO 9001 certification demonstrates that a manufacturer has implemented a robust quality management system, ensuring consistent product quality and customer satisfaction. UL certification indicates that a wire harness meets Underwriters Laboratories' safety standards, reducing the risk of electrical hazards. IPC/WHMA-A-620 is a widely recognized standard for cable and wire harness assemblies, providing guidelines for design, materials, manufacturing, and testing. Compliance with industry-specific standards, such as those for automotive, aerospace, or medical applications, is also crucial. These certifications and standards provide assurance to customers that the wire harnesses they purchase meet the highest levels of quality and safety. They also demonstrate a manufacturer's commitment to continuous improvement and adherence to best practices.

6. Automation and Technology in Wire Harness Manufacturing

Automation and technology are transforming the wire harness manufacturing industry, improving efficiency, reducing costs, and enhancing quality. Automated wire cutting and stripping machines precisely cut and strip wires to the required lengths. Automated crimping machines crimp terminals onto the wire ends with consistent force and accuracy. Automated wire harness assembly boards guide the placement of wires and connectors, reducing manual errors. Robotics are used to handle repetitive tasks, such as wire bundling and connector insertion. Computer-aided design (CAD) software is used to create detailed harness drawings and 3D models. Manufacturing execution systems (MES) track and manage the production process, providing real-time visibility and control. These technologies enable manufacturers to produce complex wire harnesses with tight tolerances and high precision, while also reducing labor costs and improving throughput.

7. Supply Chain Management for Wire Harness Manufacturers

Effective supply chain management is critical for wire harness manufacturers to ensure timely delivery of high-quality products. This involves sourcing components from reliable suppliers, managing inventory levels, and coordinating logistics. Manufacturers must establish strong relationships with suppliers to ensure consistent quality and competitive pricing. Inventory management systems are used to track component levels and prevent shortages or overstocking. Logistics planning involves optimizing transportation routes and delivery schedules to minimize lead times. Many manufacturers use enterprise resource planning (ERP) systems to integrate all aspects of their supply chain, from procurement to production to delivery. Effective supply chain management enables wire harness manufacturers to respond quickly to changing customer demands and maintain a competitive advantage.

8. Customization and Design Flexibility Offered by Wire Harness Manufacturers

One of the key advantages of using a wire harness manufacturer is the ability to obtain customized solutions tailored to specific application requirements. Manufacturers offer a high degree of design flexibility, allowing customers to specify wire gauges, connector types, routing paths, and protective coverings. Customization can also extend to labeling, color-coding, and packaging. This flexibility enables customers to optimize the wire harness for their specific needs, improving performance, reliability, and ease of installation. Manufacturers often work closely with customers throughout the design process to ensure that the final product meets all requirements. Customization can also involve the integration of additional components, such as sensors, relays, or fuses, into the wire harness. This allows for a more integrated and streamlined solution.

9. Sustainability and Environmental Considerations in Wire Harness Manufacturing

One of the key advantages of using a wire harness manufacturer is the ability to obtain customized solutions tailored to specific application requirements. Manufacturers offer a high degree of design flexibility, allowing customers to specify wire gauges, connector types, routing paths, and protective coverings. Customization can also extend to labeling, color-coding, and packaging. This flexibility enables customers to optimize the wire harness for their specific needs, improving performance, reliability, and ease of installation. Manufacturers often work closely with customers throughout the design process to ensure that the final product meets all requirements. Customization can also involve the integration of additional components, such as sensors, relays, or fuses, into the wire harness. This allows for a more integrated and streamlined solution.

10. The Future of the Wire Harness Manufacturing Industry

The wire harness manufacturing industry is poised for continued growth and innovation in the coming years. The increasing demand for electric vehicles, autonomous driving systems, and connected devices will drive innovation in wire harness technology. Miniaturization of components will enable the development of smaller and more compact wire harnesses. Wireless technology may eventually replace some wired connections, reducing the complexity and weight of wire harnesses. Smart wire harnesses with integrated sensors and diagnostics will provide real-time monitoring and predictive maintenance capabilities. 3D printing may be used to create custom wire harness components and prototypes. Automation will continue to play a key role in improving efficiency and reducing costs. The industry will also need to adapt to changing environmental regulations and increasing customer demands for sustainable products.

I hope these detailed responses are helpful! Let me know if you need anything further.