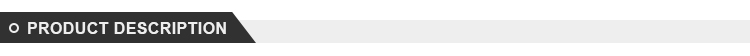

12 Pin Flat Ribbon Cable

An insulator seals a 12-pin flat cable. Commonly, ribbon cables are covered with plastic insulations like PVC, PVC is an efficient insulator with high thermal resistance (1050c)and can work under harsh environmental conditions. lt's resistant to moisture, abrasion,and oil.

,The conductors are well-separated by the plastic insulating material- There are no chances of the conductors getting into contact, which can result in shorting.

An lDC 12-pin connector flat ribbon cable is highly flexible- You can fold it over without damaging it. Both the copper conductor and insulator are designed to be flexible for any application.

- Information

An Outline of 12 Pin lDC Connector Flat Ribbon Cable

Advancements in technology are coming with more sophisticated and efficient devices. Today, we have smaller but extremely excellent laptops compared to those developed years ago. All this is coming due to improvements in specific components. Flat ribbon cables are among the ideas helping to shape the technological industry.

A 12-pin flat ribbon cable is now used for computer cabling, medical devices, gaming equipment, and so on. The 12-pin ribbon cables are preferred for their nature and shape, allowing them to be used in confined spaces. Now, let's get to understand more about this cable.

Characteristics of a 12 Pin Flat Ribbon Cable

As much as a 12-pin ribbon cable might seem similar to other flat ribbon cables, it has unique features. The specific features you will identify with the 12-pin ribbon cable are;

The cable is gray with a red side.

A 12-pin flat ribbon cable has an lDC connector with a pin pitch of 1.27 mm, 2mm, and 2.54 mm.

This cable has a plastic insulating material that can withstand a current voltage of up to 300V

The ribbon cable has a contact resistance of about 15mQ. It can work best at a temperature up to 1050

The ribbon commonly measures 7.6mm wide and 20cm in length.

Applications of a 12 Pin lDC Connector Flat Ribbon Cable

All 12-pin lDC cables must be UL 2651 Certified and ROHS compliant, among other requirements. These requirements approve they are safe for use by any individual and to the environment. Some 12-pin flat cable applications include electrical appliances, data or communication devices, LCD TV panels, DVD players, gaming equipment, hard drives, backlight panels, LED displays, medical equipment, some industrial devices, cabling in electronic boxes, and much more.

Advantages of a 12 Pin lDC Cable

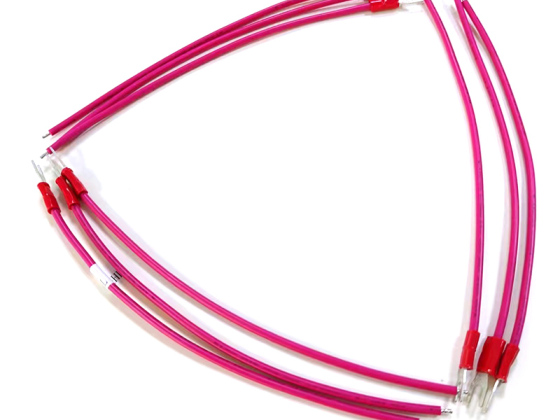

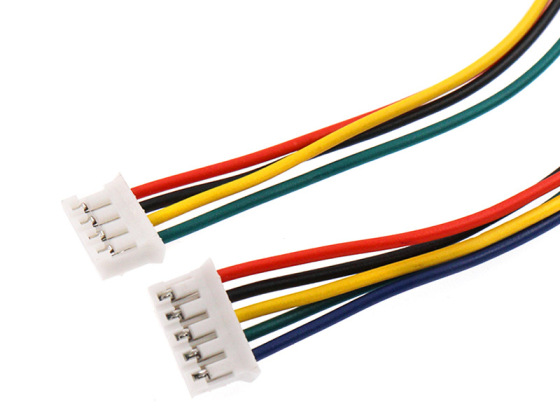

A 12-pin ribbon cable is designed to have three main components. They form the cable and ensure it functions efficiently. The cable has connectors to its ends, copper conductors, and insulation. Each plays a significant role in its performance and led to the cable's benefits like;

The cable has a high conductivity level- Copper is a great conductor with a low resistance level. This allows the cable to transmit electric power efficiently.

An insulator seals a 12-pin flat cable. Commonly, ribbon cables are covered with plastic insulations like PVC, PVC is an efficient insulator with high thermal resistance (1050c)and can work under harsh environmental conditions. lt's resistant to moisture, abrasion,and oil.

,The conductors are well-separated by the plastic insulating material- There are no chances of the conductors getting into contact, which can result in shorting.

An lDC 12-pin connector flat ribbon cable is highly flexible- You can fold it over without damaging it. Both the copper conductor and insulator are designed to be flexible for any application.

what is cable harness?

Cable assemblies are groups of cables which are arranged into a single unit for a particular purpose. Cable assemblies are also referred to as cable harnesses or wiring looms.

These cables are grouped together in precisely the required length and orientation in order to make installation easier and quicker. They often include different cable constructions, as well as varying sizes, colours and lengths depending on the application. The assemblies may be compiled with a sleeve applied overall, or taped or bound with cable ties to help group the cables together, protecting them and making them more compact to save space. Depending on the application the assembly may be fitted with various terminations, including plug or socket arrangements.

What is the Wire Harness Assembly Process?

Wire Preparation. Cut the wires to the required lengths based on the design specifications.

.Crimping or Soldering.

Terminal Assembly.

Harness Routing and Bundling.

Testing and Inspection.

Protective Covering

.Labeling and Marking.

Final Quality Check and Packaging.

Where are wiring harnesses used?

Wire harnesses are everywhere — under the hood of every car and truck on the road, and in every plane, jet, and rocket in the sky. Wire harnesses are also referred to as cable harnesses or cable assemblies. These terms all describe a systematic set of cables or wires bundled to form an integrated unit.

wire harness assembly

wire harness connectors

engine wire harness

wire harness kit

wire harness for car

car stereo wire harness

harness wire for car stereo

metra wire harness

radio wire harness

trailer hitch wire harness

wire harness clips

wire harness radio

3 wire camshaft position sensor wiring harness

5 wire blower motor harness connector

ls wire harness

painless performance wire harness

wire harness manufacturing

custom wire harness

melted cause by fire wire harness