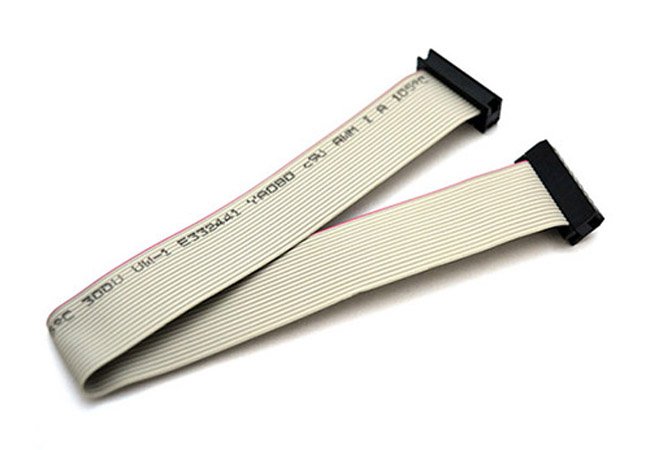

1.27mm Pitch Ribbon Cable

Manufacturing the 1.27 mm flat pitch ribbon cable ensures that it's efficient for its specified applications. UL-certified 1.27 mm pitch ribbon cables must satisfy the customer by providing durable services. The cable has a variety of advantages like;

Has PVC insulation, high-temperature resistant- protects the conductors from high temperatures that might damage the cable

The cable's insulation protects the cable from damage caused by conductors getting into contact.

A 27mm flat pitch ribbon cable is efficient for applications with limited spaces within devices.

The PVC insulation is durable- Protects the cable from abrasions caused by intense vibrations.

- Evershine

- Xiamen

- 7-15days

- 100000pcs/month

- Information

1.27mm Pitch Ribbon Cable

OEM ODM wiring Harness Factory

Product Name: Flat Ribbon Cable

Main Materials: Plastic

Pin Number:18

Pin Pitch:1.27mm

Length:30cm/11.8-inch

Withstand Voltage: 300V

Connector Type: Female Connector

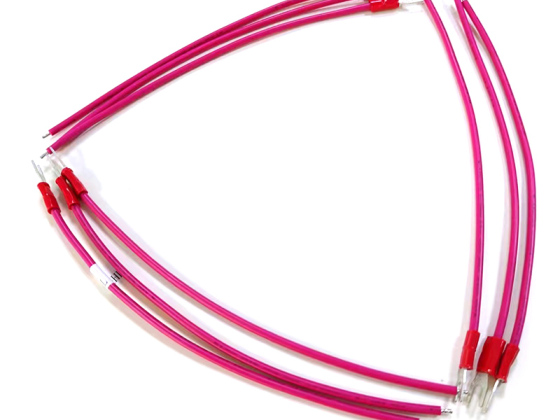

An Outline of a 1.27mm Pitch lDc Connector Ribbon Cable

A 1.27mm flat pitch ribbon cable is a flat cable comprising multiple small-grade cables. The cables are parallel to each other and resemble a piece of ribbon. This is why it was given the name "ribbon."

A 1.27mm pitch ribbon cable is connected to a 1.27mm pitch connector. This makes the ribbon cable to be used in various applications like; communication,industrial and automotive test and control applications, medical diagnostic and monitoring gadgets, etc.The cable's flatness enables it to be used in small spaces, unlike other cables.

Features of 1.27mm Pitch Connector Ribbon Cable

A 1.27 mm pitch ribbon cable comes with different characteristics from other types ofribbon cable, for example, a 2mm ribbon cable. The cable's features ensure that it's unique in its applications. These features include;

A 27 mm pitch ribbon cable has a UL 94V-0 fire rating

This type of ribbon cable that is UL-certified has a wide range of 28AWG.The cable has a temperature range of -40 to 1050C

This ribbon cable can carry a current rated at 1.0A.

Aside from the features, it's necessary to deal with only certified ribbon cables. These are cables tested and approved by companies like Underwriter Laboratories. Such a company is mandated to test and evaluate the procedures the cable manufacturer uses during the cable's manufacture. Also, you need to confirm whether 1.27 mm pitch ribbon cable you wish to purchase meets the OE specifications. Dealing with counterfeits can cause issues to a device, like malfunctioning.

Advantages of 1.27 mm Pitch Flat Ribbon Cable

Manufacturing the 1.27 mm flat pitch ribbon cable ensures that it's efficient for its specified applications. UL-certified 1.27 mm pitch ribbon cables must satisfy the customer by providing durable services. The cable has a variety of advantages like;

Has PVC insulation, high-temperature resistant- protects the conductors from high temperatures that might damage the cable

The cable's insulation protects the cable from damage caused by conductors getting into contact.

A 27mm flat pitch ribbon cable is efficient for applications with limited spaces within devices.

The PVC insulation is durable- Protects the cable from abrasions caused by intense vibrations.

Application of 1.27 mm Pitch Connector Flat Ribbon Cable

A1. 27 mm pitch ribbon cable is used in different ways. lts applications range from devices used in industrial, communication, medical, and other fields. Let's dive into the sectors you will find the ribbon cable being used;

Vehicle infotainment

Weighing systems

Solar applications

Retail and point-of-sale equipment

Medical diagnostic as well as evaluation devices@Industrial and automotive control and test

Aero and home security

Related Product

40 Pin Flat Ribbon Cable

1 Pin Flat Ribbon Cable

2mm Pitch-Ribbon Cable

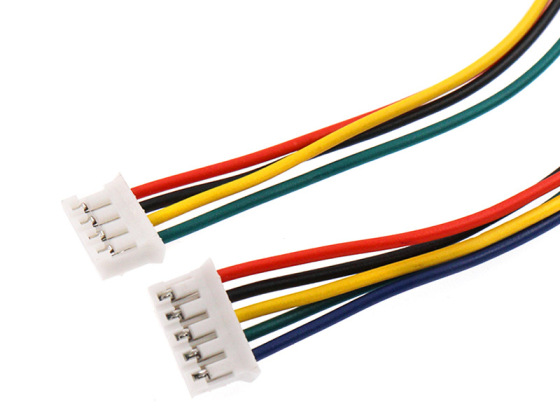

what is cable harness?

Cable assemblies are groups of cables which are arranged into a single unit for a particular purpose. Cable assemblies are also referred to as cable harnesses or wiring looms.

These cables are grouped together in precisely the required length and orientation in order to make installation easier and quicker. They often include different cable constructions, as well as varying sizes, colours and lengths depending on the application. The assemblies may be compiled with a sleeve applied overall, or taped or bound with cable ties to help group the cables together, protecting them and making them more compact to save space. Depending on the application the assembly may be fitted with various terminations, including plug or socket arrangements.

What is the Wire Harness Assembly Process?

Wire Preparation. Cut the wires to the required lengths based on the design specifications.

.Crimping or Soldering.

Terminal Assembly.

Harness Routing and Bundling.

Testing and Inspection.

Protective Covering

.Labeling and Marking.

Final Quality Check and Packaging.

Where are wiring harnesses used?

Wire harnesses are everywhere — under the hood of every car and truck on the road, and in every plane, jet, and rocket in the sky. Wire harnesses are also referred to as cable harnesses or cable assemblies. These terms all describe a systematic set of cables or wires bundled to form an integrated unit.

wire harness assembly

wire harness connectors

engine wire harness

wire harness kit

wire harness for car

car stereo wire harness

harness wire for car stereo

metra wire harness

radio wire harness

trailer hitch wire harness

wire harness clips

wire harness radio

3 wire camshaft position sensor wiring harness

5 wire blower motor harness connector

ls wire harness

painless performance wire harness

wire harness manufacturing

custom wire harness

melted cause by fire wire harness