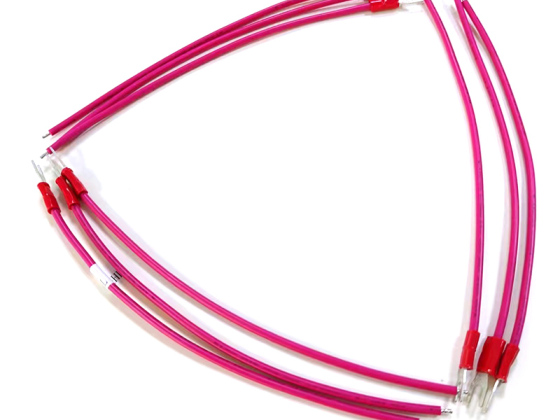

10 Pin Flat Ribbon Cable

The flat nature of a 10 pin connector flat ribbon cable allows it to be suitable for limited spaces in devices.

The cable is flexible- lt can be folded easily to leave space for other components.

Easy installation and replacement

A UL-certified 10 pin ribbon cable is reliable- it meets the expected standards to be certified.

Covered with tough insulation- Resistant to harsh temperatures and moisture reactions

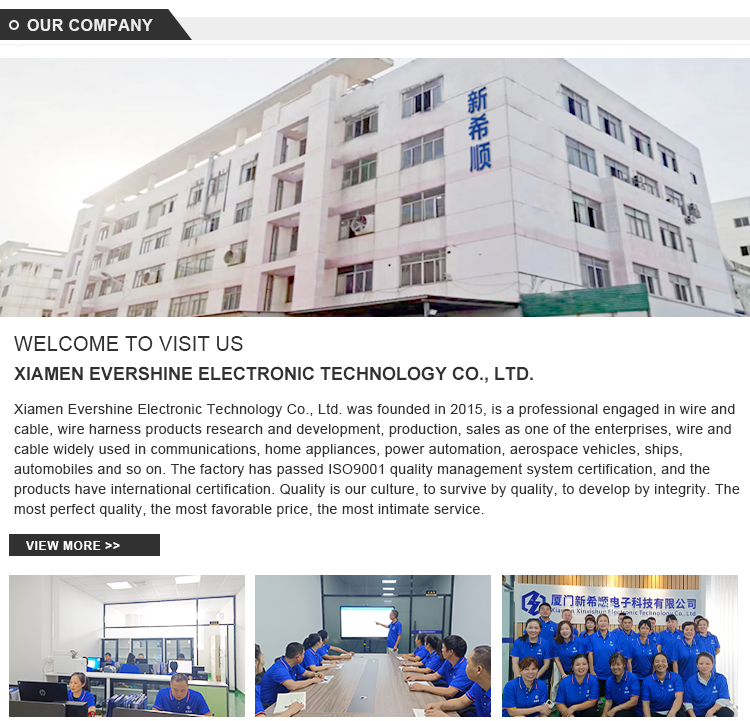

- Evershine

- Xiamen

- 7-15days

- 100000pcs/month

- Information

10 Pin Flat Ribbon Cable: The Ultimate Guide

A 10-pin flat ribbon cable is a unique type of ribbon cable and is a new practical accessory for an lDC socket. This cable is used with FPC(flexible printed circuits) products like printers, copiers, and routers.

Features of a 10 Pin Ribbon Cable

A 10-pin ribbon cable has a similar resemblance to other ribbon cables. lf you aren't conversant with their unique and distinctive characteristics, you're likely to confuse one for another. Each cable is unique to serve its purpose efficiently. Some of the 10 pin lDC ribbon cable features include;

Connected to 1.27mm,2.0mm, 2.54mm pitch connector (female connector

End-to-end: 10 pin to 10 pin

10 10-way ribbon cable is a flat ribbon

Has a plastic insulating material that can withstand high temperatures (105C)

A10-pin lDC connector flat ribbon cable can withstand a voltage up to 300 V

It can be connected to a PCB easily and directly

Reasons of Using a 10 Pin lDC Ribbon Cable

Like other flat ribbon cables, the 10-pin flat ribbon cable's design allows it to be useful for its specific applications. The manufacturers are guided by the UL and ISO 9001 specifications to provide quality cables that serve customers satisfactorily. However, checking whether a cable meets the OE specifications is also necessary. Some advantages of using a 10 pin lDC ribbon cable include;

The flat nature of a 10 pin connector flat ribbon cable allows it to be suitable for limited spaces in devices.

The cable is flexible- lt can be folded easily to leave space for other components.

Easy installation and replacement

A UL-certified 10 pin ribbon cable is reliable- it meets the expected standards to be certified.

Covered with tough insulation- Resistant to harsh temperatures and moisture reactions

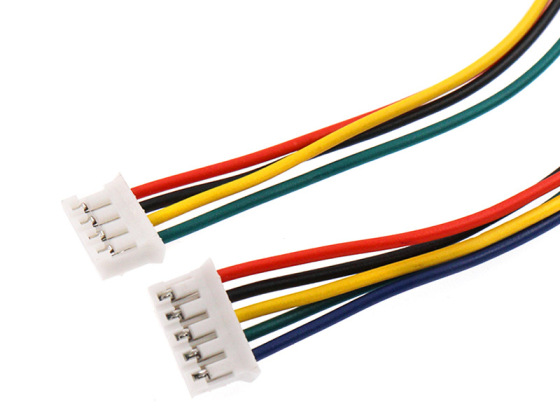

What is cable harness?

Cable assemblies are groups of cables which are arranged into a single unit for a particular purpose. Cable assemblies are also referred to as cable harnesses or wiring looms.

These cables are grouped together in precisely the required length and orientation in order to make installation easier and quicker. They often include different cable constructions, as well as varying sizes, colours and lengths depending on the application. The assemblies may be compiled with a sleeve applied overall, or taped or bound with cable ties to help group the cables together, protecting them and making them more compact to save space. Depending on the application the assembly may be fitted with various terminations, including plug or socket arrangements.

What is the Wire Harness Assembly Process?

Wire Preparation. Cut the wires to the required lengths based on the design specifications.

.Crimping or Soldering.

Terminal Assembly.

Harness Routing and Bundling.

Testing and Inspection.

Protective Covering

.Labeling and Marking.

Final Quality Check and Packaging.

Where are wiring harnesses used?

Wire harnesses are everywhere — under the hood of every car and truck on the road, and in every plane, jet, and rocket in the sky. Wire harnesses are also referred to as cable harnesses or cable assemblies. These terms all describe a systematic set of cables or wires bundled to form an integrated unit.

wire harness assembly

wire harness connectors

engine wire harness

wire harness kit

wire harness for car

car stereo wire harness

harness wire for car stereo

metra wire harness

radio wire harness

trailer hitch wire harness

wire harness clips

wire harness radio

3 wire camshaft position sensor wiring harness

5 wire blower motor harness connector

ls wire harness

painless performance wire harness

wire harness manufacturing

custom wire harness

melted cause by fire wire harness