Quick Turn Custom Wire Harness Prototype: How Low-MOQ China Suppliers Are Accelerating Global Product Development

2026-01-28 10:41In today’s fast-moving electronics and industrial markets, speed has become as critical as cost. Whether in automotive electronics, aerospace systems, power automation, or smart appliances, product lifecycles are shortening while technical complexity continues to rise. Against this backdrop, the ability to move quickly from concept to validation has become a decisive competitive advantage.

This is where the demand for Quick Turn Prototype Wire Harness services is rapidly increasing. Global OEMs and engineering teams are no longer satisfied with long lead times and high minimum order quantities. Instead, they are looking for partners that can deliver precise, reliable prototypes—fast, flexible, and in small volumes.

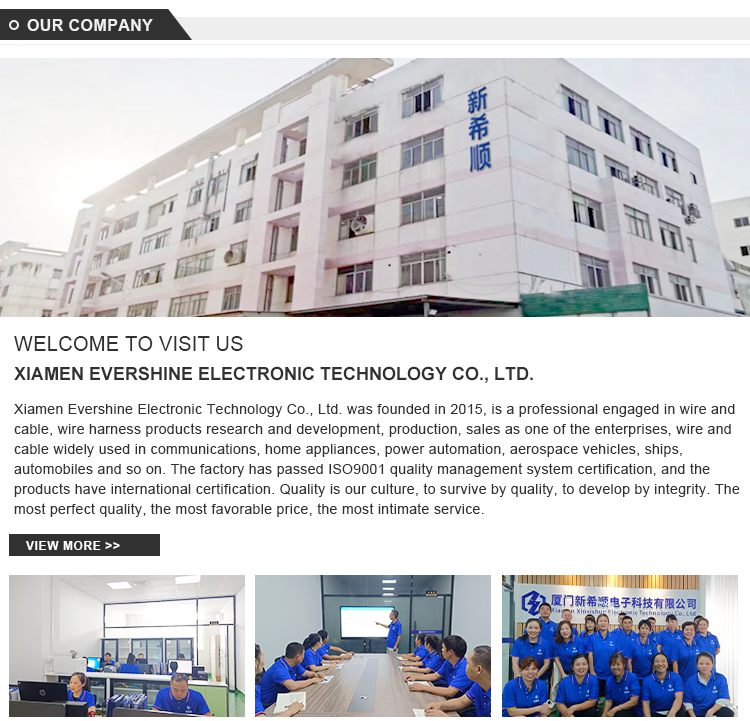

Chinese manufacturers, once associated mainly with mass production, are now reshaping their global role. Among them, Xiamen Evershine Electronic Technology Co., Ltd. is emerging as a trusted solution provider for low-volume, high-complexity wire harness development.

From Mass Production to Engineering Speed

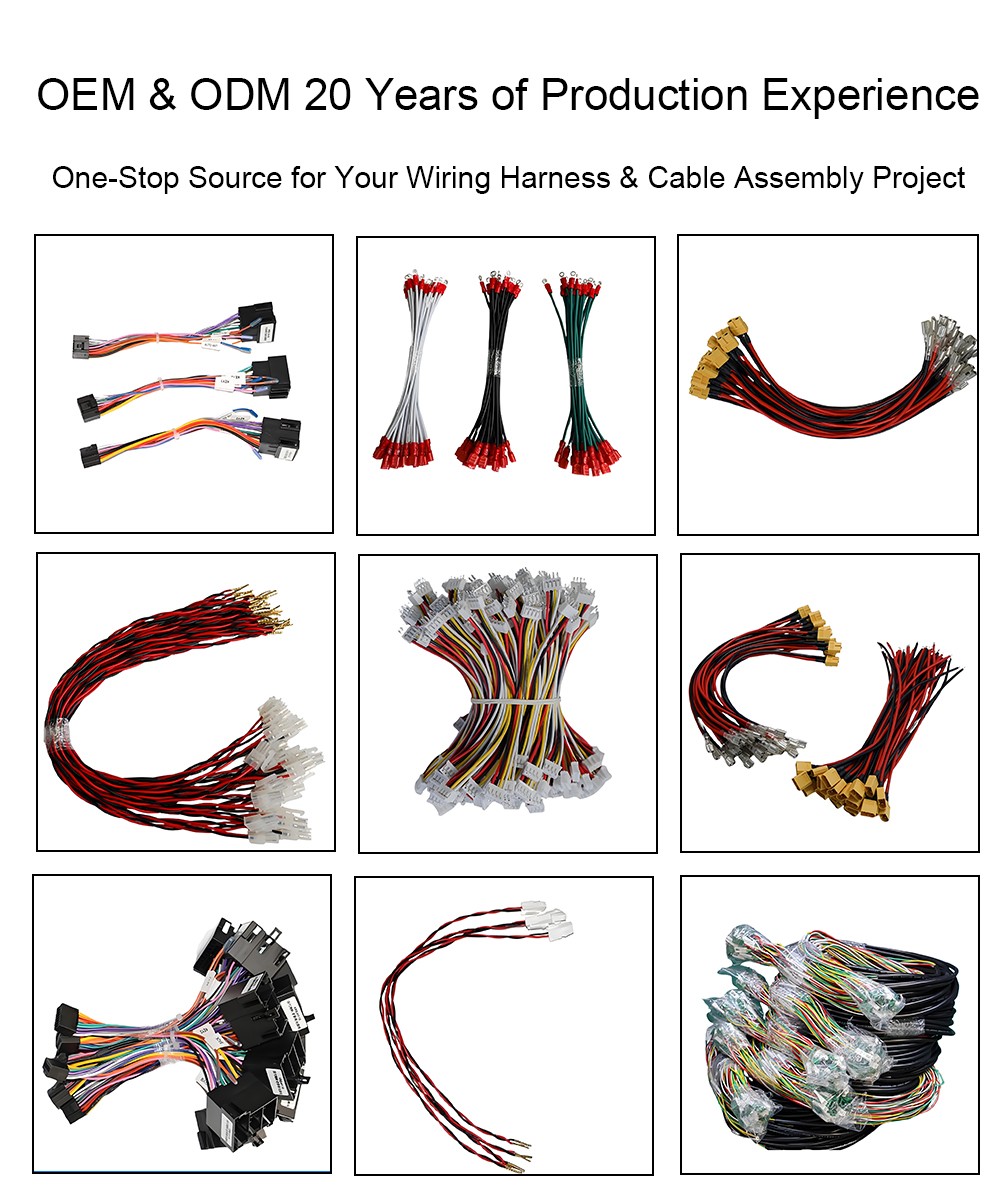

Founded in 2015, Xiamen Evershine Electronic Technology Co., Ltd. specializes in the research, development, production, and sales of wire, cable, and harness products. Its solutions are widely applied in communications, home appliances, power automation, aerospace vehicles, ships, and automobiles. Certified under ISO9001 and holding multiple international certifications, Evershine has built a quality system designed to support both prototype and production-scale requirements.

What sets the company apart is its focus on Low MOQ Wire Harness projects. By restructuring internal workflows and aligning engineering closely with production, Evershine enables customers to validate designs without committing to large quantities. This capability is increasingly valuable for startups, R&D teams, and global OEMs managing multiple product variants.

Why Low-MOQ Prototyping Is Reshaping the Industry

Traditional sourcing models often forced customers to choose between speed and flexibility. Today, that trade-off is disappearing. The rise of advanced automation, modular tooling, and digital process control has made Complex Custom Cable Assembly feasible even at low volumes.

For product developers, this shift offers three major benefits:

Faster Design Iteration

Rapid access to a Quick Turn Prototype Wire Harness allows engineers to test, modify, and refine designs without weeks of delay.Lower Development Risk

Small-batch validation reduces financial exposure, especially in early-stage projects requiring a Low MOQ Wire Harness approach.Higher Design Accuracy

Prototypes built using production-grade processes ensure that performance data reflects real-world conditions.

Industry Analysis: Key Parameters Driving Prototype Demand

| Parameter | Traditional Model | Modern Prototype Model | Impact |

| Minimum order quantity | 500–1000 pcs | 1–50 pcs | Lower entry barrier |

| Lead time | 4–6 weeks | 7–14 days | Faster validation |

| Design flexibility | Limited | High | Improved innovation |

| Assembly complexity | Medium | Very high | Precision required |

| Engineering involvement | Low | Deep | Better outcomes |

These changes explain why global buyers increasingly prefer a Wire Harness Supplier capable of balancing engineering depth with manufacturing agility.

Inside the Manufacturing Process: Turning Speed into Reliability

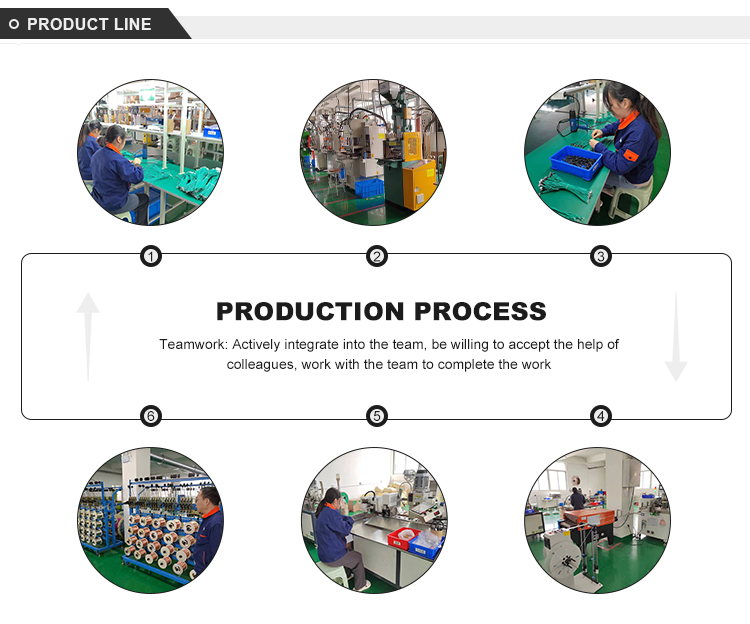

Delivering fast prototypes is not simply a matter of working faster. It requires disciplined systems and experienced execution. At Evershine, prototype workflows are designed to mirror production conditions, ensuring consistency from early samples to final delivery.

Each Wire Harness Cable Assembly undergoes controlled material selection, precision cutting, accurate crimping, and comprehensive electrical testing. This approach supports even the most Complex Custom Cable Assembly requirements, including multi-branch structures, mixed connectors, and application-specific shielding.

By integrating engineering review into every stage, Evershine ensures that each Quick Turn Prototype Wire Harness is not just fast—but dependable.

The Role of the Modern Wire Harness Supplier

Today’s customers expect more than basic assembly. A competitive Wire Harness Supplier must understand application environments, regulatory constraints, and downstream manufacturing considerations.

This is especially true for projects requiring a Low MOQ Wire Harness, where every design decision has a direct impact on performance and scalability. Through close collaboration with customers, Evershine provides early feedback on routing, material selection, and assembly feasibility—reducing costly revisions later.

FAQ: Common Questions About Quick-Turn Wire Harness Prototypes

Q1: Does low MOQ increase unit cost?

Yes, but overall development costs are often lower due to reduced risk and faster iteration enabled by Low MOQ Wire Harness services.

Q2: Can complex designs really be prototyped quickly?

With mature processes, even Complex Custom Cable Assembly can be delivered on tight schedules.

Q3: Are prototypes built differently from production parts?

At Evershine, prototype Wire Harness Cable Assembly follows production-grade standards for accurate validation.

Q4: How fast is “quick turn” in practice?

Most Quick Turn Prototype Wire Harness orders are completed within 7–14 days, depending on complexity.

Q5: What should buyers look for in a prototype supplier?

Choose a Wire Harness Supplier with strong engineering support, not just assembly capacity.

China’s Evolving Advantage in Prototype Manufacturing

China’s manufacturing ecosystem is no longer defined solely by scale. Its strength now lies in integration—engineering, supply chain coordination, and rapid execution working together.

Companies like Evershine demonstrate how Chinese suppliers can deliver high-mix, low-volume projects without sacrificing quality. By mastering Complex Custom Cable Assembly and flexible scheduling, they provide global customers with a powerful development partner rather than a distant factory.

Conclusion and Call to Action: Prototype Faster, Decide Smarter

In an environment where time-to-market defines success, fast and accurate prototyping is no longer optional. It is a strategic necessity.

Choosing a partner capable of delivering a reliable Quick Turn Prototype Wire Harness with a Low MOQ Wire Harness model enables smarter decisions, faster launches, and stronger products. With deep experience as a global Wire Harness Supplier, Xiamen Evershine Electronic Technology Co., Ltd. continues to support innovation across industries.

By combining speed, precision, and integrity, Evershine helps customers turn ideas into validated solutions—one Wire Harness Cable Assembly at a time.