Complex Custom Cable Assembly Factory: How China Engineering Support Is Redefining Global Wire Harness Manufacturing

2026-01-07 10:49As global industries move toward higher integration, smarter systems, and increasingly compact designs, the role of cable and wire harness manufacturing is undergoing a fundamental shift. No longer viewed as a secondary production task, wire harness engineering has become a core element of system reliability, performance, and lifecycle cost control.

In this new environment, manufacturers capable of delivering Complex Custom Cable Assembly with strong engineering collaboration are rapidly gaining strategic importance. China, long known for scale manufacturing, is now emerging as a global hub for technically demanding, engineering-driven wire harness solutions.

At the center of this transformation is Xiamen Evershine Electronic Technology Co., Ltd., a company that has steadily built its reputation as both a manufacturing base and an engineering partner for global customers.

From Assembly Provider to Engineering Partner

Founded in 2015, Xiamen Evershine Electronic Technology Co., Ltd. is a professional enterprise integrating research and development, production, and sales of wire, cable, and wire harness products. Its solutions are widely used in communications, home appliances, power automation, aerospace vehicles, ships, and automobiles. The factory operates under ISO9001 quality management certification, with products meeting multiple international standards.

What distinguishes Evershine is its focus on engineering participation throughout the project lifecycle. Rather than waiting for finalized drawings, the company engages early to support design optimization, manufacturability evaluation, and material selection—an approach that defines modern China Engineering Support Wire Harness capability.

Why Complexity Is Becoming the Industry Norm

Modern electronic systems demand far more than basic connectivity. Increased signal density, hybrid power-and-signal integration, and harsh operating environments are driving demand for Wire Harness Manufacturing solutions that are both electrically precise and mechanically robust.

In industries such as aerospace, automotive electronics, and industrial automation, cable assemblies must withstand vibration, temperature variation, electromagnetic interference, and long service life requirements. These demands have made Complex Custom Cable Assembly not the exception, but the standard.

To meet these expectations, manufacturers must combine skilled engineering teams with disciplined production systems—something China-based factories have rapidly developed over the past decade.

Industry Analysis: Key Parameters in Advanced Wire Harness Projects

| Parameter | Standard Projects | Complex Projects | Engineering Impact |

| Circuit density | Low–Medium | High | Routing optimization |

| Connector variety | Limited | Multiple types | Interface control |

| Environmental resistance | Basic | High | Material engineering |

| Documentation depth | Moderate | Extensive | Compliance assurance |

| Supplier involvement | Late-stage | Early-stage | Risk reduction |

These parameters explain why global buyers increasingly seek China Engineering Support Wire Harness partners rather than simple production vendors.

Manufacturing Execution: Turning Engineering into Consistency

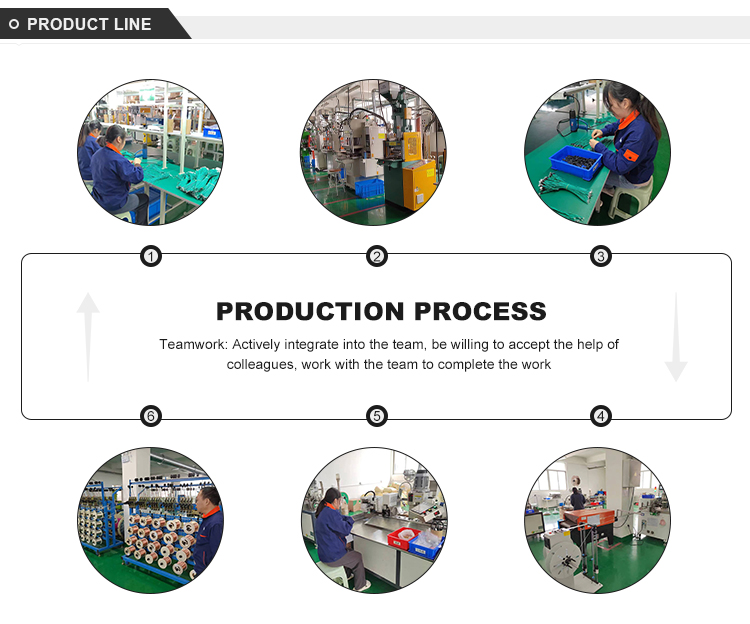

Delivering complex assemblies at scale requires more than technical knowledge—it requires repeatable execution. At Evershine, production workflows are designed to ensure that every Wire Harness Cable Assembly reflects the original engineering intent.

Processes such as controlled cutting, precision crimping, automated testing, and full traceability are integrated into daily operations. This structure supports both small-batch development and Wholesale Wire Harness supply for mature programs, without compromising quality or delivery stability.

Importantly, engineering teams remain involved throughout production, ensuring that changes are evaluated systematically rather than reactively.

The Strategic Role of Wholesale Supply in Custom Projects

While customization is critical, many global customers also require scalability. A capable supplier must transition smoothly from pilot builds to Wholesale Wire Harness production once designs are validated.

Evershine’s manufacturing model supports this progression. Early engineering engagement reduces redesign risk, allowing complex projects to move efficiently into volume Wire Harness Manufacturing without unexpected cost or quality issues. This capability is especially valuable for customers managing multi-region deployments or long product lifecycles.

FAQ: Common Questions from Global Buyers

Q1: Can complex cable assemblies be produced reliably in China?

Yes. Mature China Engineering Support Wire Harness systems emphasize process control and validation.

Q2: How early should engineering collaboration begin?

The earlier the better, especially for Complex Custom Cable Assembly projects with tight constraints.

Q3: Is wholesale production compatible with custom designs?

Absolutely. Many Wholesale Wire Harness programs begin as fully customized builds.

Q4: How is quality ensured across batches?

Standardized Wire Harness Cable Assembly processes and traceability systems ensure consistency.

Q5: What defines a capable wire harness manufacturer today?

Strong engineering depth combined with disciplined Wire Harness Manufacturing execution.

China’s New Position in the Global Wire Harness Value Chain

China’s wire harness industry is no longer defined by cost efficiency alone. Its competitive edge increasingly lies in integration—engineering insight, supply chain coordination, and scalable execution working together.

Manufacturers like Xiamen Evershine Electronic Technology Co., Ltd. illustrate how Chinese factories are evolving into solution-oriented partners, capable of supporting demanding international projects through China Engineering Support Wire Harness expertise.

Conclusion and Call to Action: Engineering-Driven Manufacturing for a Connected World

As systems grow more complex and performance margins shrink, the importance of engineering-driven manufacturing continues to rise. Choosing the right partner for Complex Custom Cable Assembly is no longer a tactical sourcing decision—it is a strategic one.

With proven experience in Wire Harness Manufacturing, scalable Wholesale Wire Harness supply, and disciplined Wire Harness Cable Assembly processes, Xiamen Evershine Electronic Technology Co., Ltd. stands ready to support global customers with reliability and integrity.

For companies seeking a partner that combines engineering insight with manufacturing strength, the future of connectivity begins here.