A Simple Guide to Cable Harness Assembly

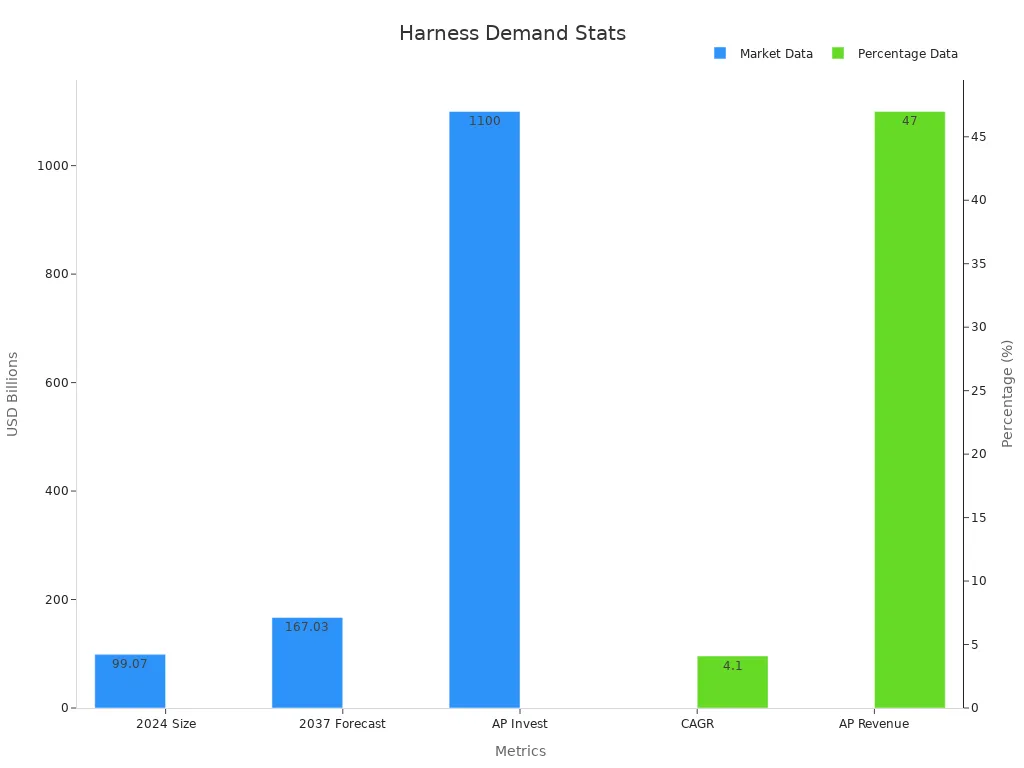

2025-06-26 16:24You need cable harness assembly to help electronic systems work well. A cable harness keeps wires neat and stops them from getting tangled. This helps power or signals move safely and quickly in cars and machines. As technology gets better, we need more cable harness solutions each year.

It is important to have custom and high-quality cable harnesses. This is even more true when you have special needs in your industry. Manufacturers use careful planning to make cable harness assembly that works well and lasts a long time.

Key Takeaways

Cable harness assembly keeps wires tidy, safe, and in order. This helps electronic systems work well and last longer. Using cable harnesses saves space and makes installation faster. It also makes fixing things easier by stopping wires from getting tangled or broken. The assembly process needs careful planning and picking the right materials. It also includes cutting, crimping, bundling, and testing to check quality. Picking good materials and following rules like IPC/WHMA-A-620 keeps things safe and working right. Custom cable harnesses are made for special jobs in cars, hospitals, and electronics. They help save time and money. Testing each cable harness assembly stops problems and keeps devices safe and working. You choose between cable harnesses and wire harnesses based on where they will be used and how safe they need to be. Cable harnesses give better protection. Do not make mistakes like bad crimping, missing labels, or skipping tests. Use checklists and good materials to avoid these problems.

What Is a Cable Harness

Definition

A cable harness is a bunch of wires or cables tied together as one unit. People use a cable harness to keep electrical wires neat in electronic systems. Manufacturers cover these wires with strong materials like sleeves or tubing. This keeps the wires safe from harm. Making a cable harness is called cable harness assembly. The steps include cutting, stripping, crimping, and tying wires to fit certain designs.

Industry standards, like IPC/WHMA-A-620, say a cable harness is an assembly with wires, connectors, and covers. These rules tell what materials to use and how to check quality. You can see cable harnesses in many things, like cars and computers. Cable assemblies often have connectors and terminals. These help connect different parts of an electronic system.

Note: Cable harness assembly is more than just putting wires together. It is a careful job that follows strict rules for safety and performance.

Purpose

A cable harness makes wiring easier and safer in complex devices. Its main job is to keep wires neat, cut down on mess, and stop tangling. Using a cable harness helps you install and fix electronic systems faster. This saves time and lowers mistakes.

Cable harness assembly also keeps wires safe from tough conditions. In cars or planes, wires face shaking, heat, and wetness. A cable harness protects them from these problems. Grouping wires also cuts down on electromagnetic interference. This helps your devices work better.

Manufacturers make cable harnesses for many uses. Some are for simple things, like toys. Others are for important systems, like medical devices or planes. The table below shows how industry standards sort cable harnesses by use:

Benefits

Cable harness assembly gives you many good things:

Improved Safety: A cable harness keeps wires safe and lowers the chance of short circuits or fires.

Space Optimization: Tying wires together saves space in devices and makes them smaller.

Faster Installation: You can put in cable assemblies quickly because wires are already grouped and marked.

Better Protection: The harness guards wires from shaking, rubbing, and wetness, so they last longer.

Easier Maintenance: Neat wires make it easy to find and fix problems.

Manufacturers use cable harness assembly to meet strict quality checks. They look for the right wire types, good crimps, and strong links. You can count on cable assemblies to give steady power and signals, even in hard places.

Tip: Always pick cable harnesses that follow industry standards. This keeps your electronic systems safe and working well.

Cable Harness Assembly Process

Design

Cable harness assembly starts with a careful design step. You plan where each wire will go and connect. People use special computer programs to make detailed plans. These plans show how the wires will fit in your device. You also decide how to group and end each wire.

You must think about where the harness will be used. Will it need to handle heat, shaking, or water? You pick covers that protect the wires and plan for any special needs. Top companies, like Xiamen Evershine, use software that follows ISO/TS 16949 rules. This makes sure your design is safe and works for both test and big projects.

Tip: Always write down your design steps, plans, and parts list. This helps you make changes and check quality later.

Material Selection

Picking the right materials is very important for cable harness assembly. You choose wires, connectors, covers, and fasteners that fit your plan. For example, you may use flame-proof covers for cars or bendy wires for small spaces.

You also look for materials that meet IPC/WHMA-A-620 and ISO 9001 rules. These rules make sure your cable harness works well and lasts long. Top companies, like Xiamen Evershine, use green materials and give proof for each batch. This careful work helps you avoid problems and make perfect products.

Cutting and Stripping

After picking your materials, you start cutting and stripping. Machines measure and cut wires to the right length. This makes sure every wire fits and looks neat. Next, you remove the cover from the ends of each wire.

You can use machines or hand tools for this job. Machines do most of the work, but people check to make sure it is right. This mix of machines and people helps you make perfect cable harnesses.

Companies like Xiamen Evershine check every wire by looking at them. They also keep records, like plans and proof, to make sure each harness is good. Doing these steps helps you build a strong base for the rest of the cable harness assembly.

Note: Using machines to cut and strip wires makes work faster and lowers mistakes. This helps you make good cable harnesses every time.

Crimping and Soldering

When you build a cable harness, you must join wires to terminals and connectors. There are two main ways to do this: crimping and soldering. Crimping uses a tool to squeeze a metal terminal onto a wire’s end. This makes the wire and terminal stay together tightly. Soldering melts a metal mix to stick the wire and terminal together. This makes a strong bond that can handle shaking and heat.

You should always check your crimps and solder joints. Make sure the connections are tight and clean, with no loose wire ends. Xiamen Evershine uses machines and skilled people for these jobs. Machines work fast and make things exact. Skilled workers do tricky or special jobs. Using both helps the company make perfect cable harnesses.

Tip: Always pick the right crimping tool for each terminal. This keeps your cable harness safe and strong.

Layout and Bundling

After crimping and soldering, you need to put the wires in the right order. You follow the plan to lay out each wire. This keeps the cable harness neat and simple to install. Boards or templates help you place the wires correctly. These tools stop mistakes and keep wires from crossing.

Next, you bundle the wires together. You use cable ties, sleeves, or tubing to group them. This keeps the wires safe from harm and makes the harness easy to move. Xiamen Evershine uses machines and careful hand work for bundling. This makes sure every cable harness meets high quality rules.

You should put labels on each bundle or wire. Labels help you find the right wire when you install or fix things. Good layout and bundling save time and lower mistakes.

Testing

Testing is the last step in making a cable harness. You must check every harness before sending it out. Testing finds problems like bad connections, shorts, or wrong wiring. Special machines test if the wires are connected right and safe. These machines send signals through the wires and check the paths.

Xiamen Evershine uses advanced machines and strict checks for testing. Every cable harness gets checked many times. Skilled inspectors look for problems you can see and test how the wires work. This makes sure you get a cable harness you can trust.

Note: Never skip testing. Even one bad connection can break a device. Careful testing keeps your customers safe and protects your good name.

Cable Harness vs. Wire Harnesses

Key Differences

You might hear cable harness, wire harness, wiring harness, and cable assembly. These words sound alike but mean different things. A cable harness, or cable assembly, puts many wires or cables together in one strong cover. This cover is made from rubber, vinyl, or hard plastic. You use cable harness assembly when wires need extra safety in tough places.

A wire harness ties wires together but uses lighter covers like tape or sleeves. Each wire in a wire harness has its own insulation. The group does not always have a thick outside cover. Wire harnesses help keep wires neat and easy to move in devices.

Wiring harness is another name for wire harness. Both help you organize wires. But cable harness assembly gives more safety and lasts longer.

When to Use Each

Pick cable harness assembly if you need strong safety from heat, water, or shaking. For example, use cable harnesses in cars, planes, or outdoor machines. These places can hurt wires, so you need a tough outside layer.

Wire harnesses are good when you want to save money and do not need heavy safety. You see wire harnesses in home electronics, appliances, or office tools. These places are not harsh, so light covers work fine.

If you build big wire harnesses for machines or control panels, you might use both types. Use cable harness assembly for main power wires. Use wire harnesses for smaller signal wires. This way, you save money and keep things safe.

Pros and Cons

You should look at the good and bad sides before you pick cable harness assembly or wire harnesses. The table below shows how they are different:

The EN6059-502 test shows cable harnesses with thick covers keep wires safer from sparks and damage. Use cable harness assembly for big jobs with lots of power and thick wires. Wire harnesses with thin covers are good for small wires and less power.

Industry stories show that careful plans and checks in big wire harnesses lower mistakes and make work faster. Using 3D models and cross-section checks helps you stop too many wires in one bundle. This makes your work easier. You can handle many wire harness types in one job, which saves time and money.

Tip: Always pick what fits your project best. Use cable harness assembly for safety and long life. Pick wire harnesses if you want to save money and work in safe places.

Components

Wires and Cables

You always begin with the right wires and cables. These are the main parts of your system. High-purity copper conductors help electricity move well. Heat-resistant polymers like PTFE or silicone cover the wires. These covers help cable assemblies last longer in tough places.

When picking wires and cables, think about voltage, current, and signal type. Cars and planes need wires that handle heat and shaking. Some manufacturers use Poly-ether-ketone-ketone (PEKK) for very hot places. You can also find UV-resistant jackets, like in CDM Electronics’ RF jumpers, that last over 20 years outside.

Tip: Always look for quality marks like IPC/WHMA-A-620, UL, and RoHS. These show your wires and cables are safe and work well.

Connectors

Connectors join wires to devices, boards, or other cables. They are important parts of cable harness assembly. You need connectors that fit your project’s needs. Fischer Connectors’ cable assemblies use overmolded connectors for bend safety and sealing. These connectors can handle fast data, like Ethernet up to 10 Gb/s and USB 3.2 Gen 2.

Look for connectors tested for rubbing, shocks, and EMI. Some, like Amphenol Pcd’s, are made for tough places and military jobs. These connectors often have AS9100:D:2016 and ISO 9001:2015 marks. You can trust them in important systems.

Key connector features:

Strong locking parts

Resist chemicals and water

Easy to put in and take out

Work with fast data

Always check that your connectors fit your cable harness assembly plan. This helps you stop connection problems and downtime.

Sleeves and Tubing

Sleeves and tubing keep wires safe from harm. They protect against heat, rubbing, and chemicals. Heat shrink tubing is often used in cable assemblies. It seals tight and keeps water out. Some sleeves, like nylon or PTFE, make cables stronger and more bendy.

You can get sleeves and tubing that block UV rays, salt spray, and high heat. For example, HellermannTyton’s PA66HIRHSUV ratchet P-clamps use strong materials for hard jobs. These sleeves and clamps are easy to use and need no tools.

Benefits of good sleeves and tubing:

Stop wires from getting cut or worn

Keep cables tidy and neat

Help cable harness assembly last longer

Always pick sleeves and tubing that fit your project’s place. This keeps your cable assemblies safe and working well.

Fasteners

Fasteners hold your cable harness assembly together. You use them to keep wires and cables in place. These small parts make sure your harness stays neat and secure. You can choose from many types of fasteners. Each type works best for a certain job.

Common fasteners include:

Cable ties: You wrap these around wire bundles. They keep wires tight and organized.

Clamps: You use clamps to attach harnesses to panels or frames. They stop wires from moving or shaking.

Mounting clips: You snap these onto surfaces. They hold the harness in place without tools.

Adhesive mounts: You stick these to flat surfaces. They work well when you cannot drill holes.

Grommets: You use grommets to protect wires as they pass through sharp edges or holes.

You must pick fasteners that match your environment. For example, nylon cable ties work well in dry places. Stainless steel ties resist heat and chemicals. In automotive cable harness assembly, you often see heat-resistant clamps and vibration-proof clips.

Tip: Always check that your fasteners fit your harness size and the space in your device. This helps you avoid pinched wires or loose bundles.

The right fasteners help you build a strong and safe cable harness assembly. They also make repairs and upgrades easier.

Labels

Labels help you identify wires and cables in your cable harness assembly. You use labels to mark each wire, bundle, or connector. This makes installation and maintenance much faster. You can spot problems or make changes without guessing.

You have several labeling options:

Heat shrink labels: You slide these over wires and shrink them with heat. They stay in place and resist wear.

Wrap-around labels: You wrap these around wires or cables. They show information on both sides.

Flag labels: You attach these like a flag. They give you more space for text or codes.

Printed sleeves: You slide these over bundles. They work well for large harnesses.

A good labeling system uses clear text, numbers, or color codes. You can print labels with barcodes or QR codes for fast scanning. In the components of cable harness assembly, labels play a key role in quality control. They help you track each part from start to finish.

Note: Always use labels that resist heat, moisture, and chemicals. This keeps your cable harness assembly readable and reliable for years.

Customization

Tailored Solutions

You need cable harness assembly that fits your needs. Xiamen Evershine makes custom wire harnesses for special projects. Their team helps you from the start to the end. You can pick the wire type, connector, and cover. This way, your wiring harness matches your device and where it will be used.

Xiamen Evershine has many products to choose from. You can ask for SH1.0mm terminal wire harnesses for small electronics. If you want fast charging and data, pick USB Type-C cables. For electric cars, order automotive wire harnesses for high power and safety. Their engineers use smart design tools to make sure each cable harness assembly fits your needs.

Tip: Custom solutions save you money and time. You get a product that works well the first time.

Industry Applications

Custom wire harness and cable assemblies are used in many industries. Each industry has its own needs. Medical devices need cable assemblies that follow strict rules. Heavy machines need wire harnesses that can handle heat, water, and shaking. Xiamen Evershine gives strong solutions for these hard jobs.

Here is a table that shows how custom harnesses help different industries:

You can find real stories from many fields. For example, custom wire harnesses help battery systems, generator sets, and vehicles. These special solutions lower costs, improve quality, and make building faster. You also get better products and easier setup.

Custom cable harness assembly is used for:

Appliances and electronics

Boats and watercraft

Utility and recreational vehicles

Small engines and lawn tools

Flexibility

Custom cable harness assembly gives you more choices. You can change the design for new devices or new rules. Xiamen Evershine can quickly adjust to your project. Their team can build wire harnesses with many parts and connectors. You can make more products without losing quality.

Custom wire harnesses let you pick materials that fit your budget and needs. You can choose green options or strong parts. This helps you keep up in a fast market. Big wire harnesses for machines or vehicles may need last-minute changes. Xiamen Evershine’s process lets you update designs without waiting long.

Note: Flexible cable harness assembly means you always get the right product, even if your needs change.

Quality Considerations

Standards

You must follow strict standards for cable harness assembly. These rules help keep every product safe and reliable. The IPC/WHMA-A-620 certification is the main global standard for wire and cable harness assemblies. This certification shows you use the best steps and keep quality high.

IPC/WHMA-A-620 needs trained inspectors who know the rules.

You have to use special tools to find hidden problems.

You get reports that help you make smart choices.

Certified inspectors check for good labels, strong crimps, and safe soldering.

Many industries use these standards, like cars, planes, telecom, and medical devices.

Xiamen Evershine always follows these rules. Their team checks quality and keeps records for every cable harness assembly. This helps you avoid mistakes and keeps your products working well.

Tip: Always ask your supplier if they follow IPC/WHMA-A-620 or other top standards. This keeps your cable harness assembly safe and ready for tough jobs.

Testing Methods

Testing is very important in cable harness assembly. You need to test every harness before using it. This step finds problems early and keeps your devices safe.

You can use different testing methods:

Visual Inspection: You look for broken wires, bad crimps, or missing labels.

Continuity Testing: You check if electricity flows through each wire.

Pull Testing: You pull on wires to see if they stay in place.

High-Voltage Testing: You test if the harness can handle strong power.

Labeling Compliance: You make sure every label is clear and correct.

Xiamen Evershine uses machines and skilled workers for testing. Their team does real-world tests to see how cable harness assemblies work under stress. They also use eco-friendly materials and test them for safety and strength. This helps you get a product that lasts longer and is better for the environment.

Note: Never skip testing. Even one missed step can cause a device to fail or be unsafe.

Common Mistakes

You can stop many problems in cable harness assembly by knowing the most common mistakes. Here are some issues you should watch for:

You should always follow your checklist and keep good records. This helps you catch mistakes early and fix them fast. Xiamen Evershine uses green materials and strict checks to help you avoid these problems.

Callout: Quality control is not just about passing tests. It is about building trust with your customers and making sure every cable harness assembly works as promised.

Wire Harnesses in Industry

Automotive

Wire harnesses are in almost every car today. They link things like headlights and driver-assist systems. As cars get smarter and use more electricity, cable harness assembly becomes more important. These systems help keep your car safe and working right.

The market for automotive wire harnesses is getting bigger. Experts think it will reach $75.6 billion by 2033. In 2023, it was $50.6 billion. Asia-Pacific has the largest share, almost half. Companies like Yazaki Corporation lead the way. Xiamen Evershine also makes good solutions for electric and smart cars.

Cable harness assembly in cars must handle high voltage and fast data. It also needs to work in hard places. Xiamen Evershine gives custom wire harnesses for electric cars. Their insulation can take heat over 150°C. Their team helps you with support and quick answers. This keeps your projects moving.

Tip: Pick a partner who knows how complex car wiring is. This helps your cars stay safe and work well.

Electronics

Wire harnesses are very important in electronics. You see them in computers, servers, and smart gadgets. They keep circuits neat and protect signals from problems. Using cable harness assembly in electronics makes devices smaller and safer. It also makes repairs easier.

Xiamen Evershine makes custom wire harnesses for electronics makers. You can get USB Type-C harnesses for fast charging. You can also get SH1.0mm terminal harnesses for small gadgets. Their team uses strong tests to make sure each harness is high quality.

You get fast production and good support after buying. If you have a problem, Xiamen Evershine’s experts help you fix it fast. This support helps you give better products to your customers.

Note: Good wire harnesses help your devices work better and break less.

Industrial

Factories and big machines need cable harness assembly to work well. Industrial wire harnesses must handle shaking, dust, and heat. You need harnesses that last a long time in tough places.

Xiamen Evershine gives custom wire harnesses for robots, automation, and power systems. You can pick materials that fight oil, chemicals, and heat. Their engineers help you design harnesses that fit your machines.

You also get strong support after buying. If your machine needs fixing, Xiamen Evershine gives advice and spare parts. This keeps your work going and stops long delays.

Main benefits for factories:

Harnesses made to fit your machines

Strong materials for hard jobs

Fast help and spare parts

Callout: Good cable harness assembly keeps your factory working and helps your business grow.

Consumer Devices

You use cable harness assembly in your daily life. You may not even notice it. Many things like smartphones, laptops, and game consoles need wire harness to work well. Home appliances also use wire harness for safety and good performance. These devices need small wiring that fits tight spaces. The wiring must also handle lots of use.

When you use your phone or TV, you expect it to work. Cable harness assembly helps make this happen. Each wire harness is made to fit your device’s shape and needs. This careful design keeps wires from breaking or getting tangled. Your device stays safe, even if you move it a lot.

Wire harness is found in many home gadgets. Washing machines use cable harness assembly to link the motor, sensors, and controls. Coffee makers use wire harness to connect heaters and switches. Smart speakers and wearables use tiny cable harness assembly. These help send power and data.

Tip: Pick brands that use good cable harness assembly. This helps your devices last longer and stay safe.

Xiamen Evershine helps top electronics brands with custom wire harness. Their team works with you to design cable harness assembly for your product. You can pick special connectors or green materials. You can also add extra shielding for better results. Their fast work and support help you launch new products quickly. They also help you fix problems fast.

Here are some real examples of cable harness assembly in devices:

Smartphones: Flexible wire harness links the battery, screen, and camera.

Laptops: Cable harness assembly connects the keyboard, display, and USB ports.

Game Consoles: Wire harness joins power, controllers, and fans.

Home Appliances: Cable harness assembly runs sensors, motors, and control boards.

You count on cable harness assembly for safe and easy-to-use devices. Xiamen Evershine’s skill in wire harness design helps you enjoy technology that fits your life.

You get the best results when you do every step carefully in cable harness assembly. Custom solutions help keep you safe, make cables last longer, and save space. Quality is important at each part of the process. Find partners who can give you:

Neat wiring that makes work areas safer

Cables that last longer and do not break easily

Designs that save space in small devices

Certified quality and fast delivery

Begin your project with a good plan and people you trust. Ask experts for advice and help when you need it.

FAQ

What is cable harness assembly?

Cable harness assembly means putting wires or cables together in one group. You keep the wires neat and safe. This makes it easy to put them in cars or devices.

Why should you use cable harness assembly in your project?

Cable harness assembly keeps wires safe from harm. It saves time when you set up your project. It also stops wires from getting tangled and makes fixing things easier.

How do you choose the right materials for cable harness assembly?

You pick materials that fit your project’s needs. Choose wires, connectors, and covers that work with heat, water, or shaking. Always check for quality marks before you begin.

Can you customize cable harness assembly for special applications?

Yes, you can get cable harness assembly made just for you. Pick the wire, connector, and cover that fit your job. Custom harnesses meet all your safety and technical needs.

How do you test a cable harness assembly?

You test cable harness assembly by checking if wires connect right. Use machines and look at the wires to find problems. Testing makes sure your harness is safe and works well.

What industries use cable harness assembly?

Cable harness assembly is used in cars, electronics, factories, and home devices. Each area uses harnesses to keep wires neat and safe. They also help meet strict quality rules.

How do you maintain a cable harness assembly?

Check your cable harness assembly often for damage or loose wires. Change any bad parts fast. Good care stops problems and keeps your system working.

What are common mistakes in cable harness assembly?

Some mistakes are bad crimps, missing labels, or not testing. You can stop these by using a checklist and good materials. Always test each cable harness assembly before you use it.