A New Height of China’s Smart Manufacturing: How Flexible Custom Wire Harnesses Are Reshaping the Global Electronics Industry Chain

2025-12-17 10:31As the global electronics industry undergoes deep structural transformation, “Made in China” is quietly completing a critical upgrade—from scale-driven manufacturing to system-level capability building.

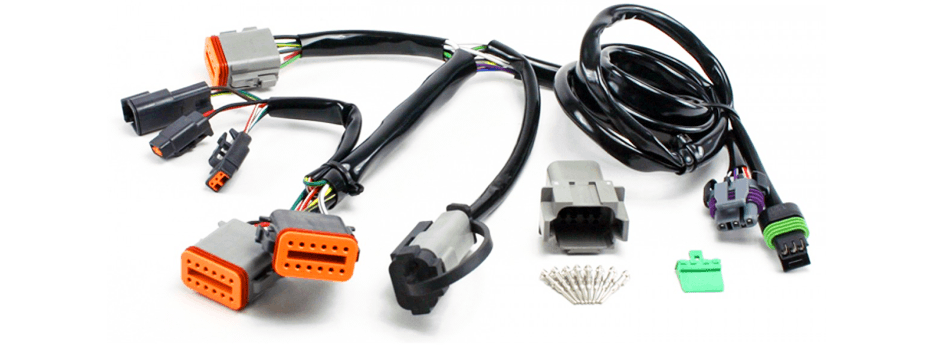

In particular, within the wire harness sector—long regarded as a supporting component of electronic systems—Chinese manufacturers are redefining global value distribution through flexible customization, rapid response, and smart manufacturing.

Represented by companies such as Xiamen Evershine Electronic Technology Co., Ltd., a new generation of manufacturers is leveraging flexible custom wire harness solutions to move China from a “wire harness processing base” to a core solution provider within the global electronics supply chain. This shift is no longer incremental; it is fundamentally reshaping how global electronics systems are designed, produced, and delivered.

1. From Standardization to Flexibility: A Structural Turning Point in the Wire Harness Industry

For decades, the wire harness industry relied heavily on standardized, large-volume production. However, rapid growth in sectors such as new energy, smart home appliances, industrial automation, aerospace, and intelligent transportation has introduced a new reality: low-volume, high-mix, and high-complexity electronic systems.

Traditional production models are no longer sufficient. In their place, Flexible Wire Harness Manufacturing has emerged as the new industry standard. Through modular design, reconfigurable processes, and fast changeover capabilities, wire harnesses are evolving from simple connectors into integral components of system architecture.

China’s manufacturing ecosystem—supported by a complete supply chain and strong engineering responsiveness—has adapted quickly, forming a globally competitive model that is difficult to replicate elsewhere.

2. China’s Second Growth Curve in Wire Harness Manufacturing

The competitive advantage of Chinese wire harness manufacturers is no longer based solely on cost. Today, it is increasingly built on technical capability, delivery speed, and system-level understanding.

Founded in 2015, Xiamen Evershine Electronic Technology Co., Ltd. specializes in the R&D, production, and sales of wires, cables, and wire harness products. Its solutions are widely applied in communications, home appliances, power automation, aerospace, ships, and automobiles. Certified under the ISO9001 quality management system and holding multiple international certifications, Evershine has fully aligned its manufacturing standards with global markets.

From the perspective of international customers, Evershine has steadily established itself as a reliable China OEM Wire Harness Supplier, offering not only manufacturing capacity but also engineering collaboration and problem-solving expertise.

3. How Flexible Customization Is Truly Reshaping the Industry Chain

The reshaping of the industry is not a slogan—it is visible in three concrete dimensions:

1. Earlier Engineering Involvement

Under the framework of Smart Wire Harness Solutions, wire harness manufacturers are no longer passive recipients of drawings. Instead, they actively participate in interface definition, routing optimization, and reliability evaluation at the early stages of system design.

2. Shorter Lead Times, Faster Iteration

With Quick Turnaround Cable Assembly, delivery cycles for small-batch customized harnesses have been reduced from weeks to days, significantly accelerating product iteration for OEMs and system integrators.

3. Optimized Cost Structures

Flexible manufacturing reduces trial-and-error costs and inventory pressure, making customization economically viable. This is a key reason why the Custom Wire Harness China Factory model is gaining strong acceptance among European and North American clients.

4. Industry Analysis: Key Parameters of the Global Flexible Wire Harness Market

| Key Indicator | 2024 | Forecast 2027 | Trend |

| Global wire harness market size | USD 92 billion | USD 115 billion | Steady growth |

| Share of customized harnesses | 28% | 41% | Rapid increase |

| China’s export share | 34% | 42% | Continuous expansion |

| Average delivery lead time | 18–25 days | 7–12 days | Significant reduction |

| Penetration of flexible manufacturing | 31% | 55% | Becoming mainstream |

The data clearly shows that Flexible Wire Harness Manufacturing and Quick Turnaround Cable Assembly are now decisive factors in global sourcing decisions—areas where Chinese manufacturers demonstrate strong competitive advantages.

5. Evershine’s Practical Approach: Not “Doing More,” but “Doing It Right”

At Xiamen Evershine, flexible manufacturing is translated into tangible system capabilities:

Modular process design enabling parallel production of multiple models

Close coordination between engineering and production to support Smart Wire Harness Solutions

Rapid prototyping and small-batch production systems enabling Quick Turnaround Cable Assembly

Full-process quality traceability meeting international compliance requirements

These capabilities position Evershine not only as a Custom Wire Harness China Factory, but also as a long-term development partner embedded in customers’ product lifecycles.

6. FAQ: Top Questions from Global Customers

Q1: Does flexible customization increase costs?

A: Not necessarily. With Flexible Wire Harness Manufacturing, overall costs are often reduced by minimizing rework and excess inventory.

Q2: Are Chinese suppliers suitable for small-batch projects?

A: Mature China OEM Wire Harness Suppliers have made small-batch production a core capability.

Q3: Is delivery lead time stable?

A: With established Quick Turnaround Cable Assembly systems, short and reliable lead times are now repeatable.

Q4: Does customization affect reliability?

A: Under Smart Wire Harness Solutions, reliability is often improved through application-specific optimization.

Q5: How should buyers select the right Chinese wire harness partner?

A: Focus on whether the supplier truly operates as a Custom Wire Harness China Factory with engineering depth, not just assembly capacity.

7. From “Made in China” to a Global Collaboration Hub

The role of Chinese wire harness manufacturers is undergoing a fundamental transformation—from cost-driven executors to strategic collaboration nodes within the global electronics industry chain.

Companies like Xiamen Evershine Electronic Technology Co., Ltd. are integrating engineering insight, manufacturing execution, and delivery efficiency through Smart Wire Harness Solutions, driving the industry toward greater efficiency, resilience, and predictability.

8. Conclusion and Call to Action: Flexible Manufacturing, Connecting the Future

As electronic systems grow more complex, true scarcity lies not in capacity, but in the ability to understand requirements quickly and deliver reliably.

Flexible custom wire harnesses have become a defining symbol of China’s smart manufacturing evolution. Choosing a partner with proven Flexible Wire Harness Manufacturing capability means choosing efficiency, quality, and long-term value.

Xiamen Evershine Electronic Technology Co., Ltd. remains committed to professionalism, integrity, and technical excellence—serving as a trusted China OEM Wire Harness Supplier and connecting critical systems across the global electronics industry.