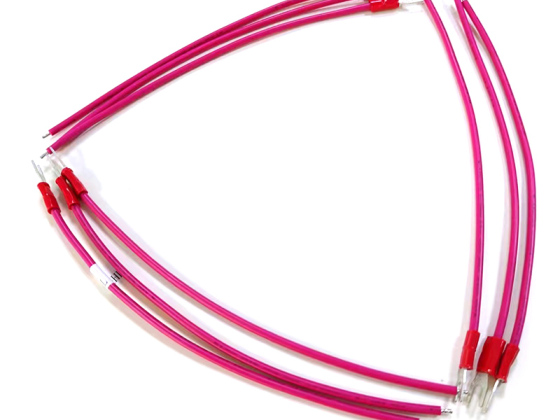

Molex Mini-Fit Jr. Cable Assembly

Molex Mini-Fit Jr. Cable Assembly

Molex Mini-Fit Ir.cable assembly is a cable with a MolexMini-Fit Jr. connector.

The Molex Mini Fit Jr. connector is specifically designed tooffer the best locking system. Owing to this the assemblyhas the ability to withstand high-density applications thatnecessitate either wire-to-wire or wire-to-boardconfigurations.

- Information

Molex Mini-Fit Jr. Cable Assembly

OEM ODM wiring Harness Factory

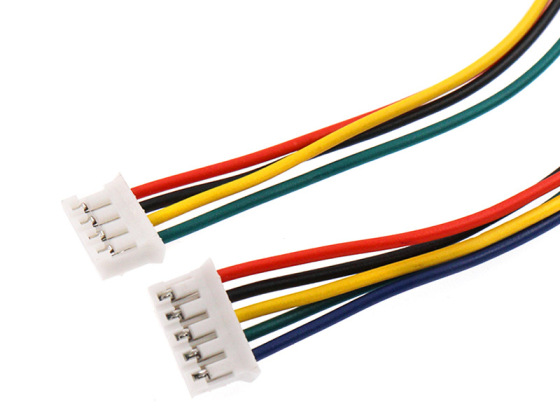

Customized Male to Female Wire Harness

Terminal wire 1.25 air docking Cable Harness

Terminal Wire Harness Kit manufacturer

Custom Cable Assembly

In Consumer

4.2mm Pitch Molex Mini-Fit Jr.overmolded cable assemblies and wire harnesses for machinery and equipment power connection.

What are the types of Molex Mini-Fit Jr. connectors?

They offer a wide range of different family connectors, namely;

1. Mini-Fit BMI

2. Mini-Fit TPA

3. Mini-Fit Plus HCS

4. Mini-Fit Plus HMC

5. Mini-Fit RTC

Here are a few reasons for making the Molex Mini Fit Jr. cable the best choice for both industrial and consumer applications.

The Molex Mini-Fit Jr. Cable assembly can either be available on a single-row or the dual-row pin choice..

Molex Mini-Fit Jr Cable Assembly

This section will briefly touch on how Molex Mini-fit Jr. cables are assembled.

Firstly, it’s important to clarify what Molex Mini-Fit Jr. cable assembly is – this is a group of wires or cables usually encased in a singular tube.

What is Molex Mini-Fit Jr cable assembly used for?

Molex Mini Fit Jr. cable assembly has many uses that suit various businesses from all industries that need electronic equipment. Thanks to cable assemblies, since they’re developed to hold and organize – many different electrical wires are now safe and easy to be accessed. This makes it preferably used in a variety of indoor and outdoor settings.

What are some of the available features of Molex Mini-Fit cable assembly?

Molex Mini-Fit Jr. Discrete Cable Assemblies

The Discrete cable assembly has various cable lengths with a 9A maximum current rating of 9A and a 4.20mm pitch connector. For design flexibility, they are available in single- and dual-row configurations hence options of female-to-female (socket-to-socket) or female-to-pigtail (socket-to-cable).

The Molex Mini-Fit Jr. Discrete Cable wire gauges range from 18 AWG to 16 AWG. Off-the-shelf, standard Mini-Fit TPA2 and non-TPA connectors are configured with multi-color cables to ensure correct connections. The PCB header is mapped pin-to-pin from the receptacle to reduce engineering time and resources. Being UL-approved, these discrete wires meet quality standards and are ready to use in electronic appliance applications.

Molex OTS Mini-Fit Jr. Overmolded Cable Assemblies

Molex Off-the-Shelf (OTS) Mini-Fit Jr. Over-molded cable assemblies can deliver a current rate of up to 6.0A, provide assurance of terminal positions, and prevent accidental injury un-mating via positive lock housings that ensure connectors are fully mated with an easy-to-operate thumb latch. The Molex OTS Mini-Fit Jr. Overmolded Cable Assemblies include various circuit sizes and lengths depending on the OTS version. The cable helps in reducing the mechanical stress on wires and terminals with over-molded strain relief.

Since Molex Mini-Fit cable assemblies are UL approved, the designs of the cable assemblies provide one-source solutions which offer ease of prototyping, design, and production. This eliminates the requirements of customers’ design and the need to find another vendor to build assemblies since they are ready to use in electronic appliance applications

Company Information:

Xiamen Evershine Electronic Technology Co., Ltd. was founded in 2015, is a professional engaged in wire and cable, wire harness products research and development, production, sales as one of the enterprises, wire and cable widely used in communications, home appliances, power automation, aerospace vehicles, ships, automobiles and so on.

The factory has passed ISO9001 quality management system certification, and the products have international certification. Quality is our culture, to survive by quality, to develop by integrity. The most perfect quality, the most favorable price, the most intimate service.

Now we mainly offer you the wires products list as various electronic wire harness wiring design, custom vehicle wiring harness, home appliance wire harness, customized industrial wire harness, computer wire harness, over-molded cable connectors, terminal block connectors, power cable types, Products have been widely used in office equipment, communications, household appliances, industrial automation, automobile, etc.

What is Cable Harness?

Cable assemblies are groups of cables which are arranged into a single unit for a particular purpose. Cable assemblies are also referred to as cable harnesses or wiring looms.

These cables are grouped together in precisely the required length and orientation in order to make installation easier and quicker. They often include different cable constructions, as well as varying sizes, colours and lengths depending on the application. The assemblies may be compiled with a sleeve applied overall, or taped or bound with cable ties to help group the cables together, protecting them and making them more compact to save space. Depending on the application the assembly may be fitted with various terminations, including plug or socket arrangements.

What is the Wire Harness Assembly Process?

Wire Preparation. Cut the wires to the required lengths based on the design specifications.

.Crimping or Soldering.

Terminal Assembly.

Harness Routing and Bundling.

Testing and Inspection.

Protective Covering

.Labeling and Marking.

Final Quality Check and Packaging.

Where are wiring harnesses used?

Wire harnesses are everywhere — under the hood of every car and truck on the road, and in every plane, jet, and rocket in the sky. Wire harnesses are also referred to as cable harnesses or cable assemblies. These terms all describe a systematic set of cables or wires bundled to form an integrated unit.

wire harness assembly

wire harness connectors

engine wire harness

wire harness kit

wire harness for car

car stereo wire harness

harness wire for car stereo

Metra wire harness

radio wire harness

trailer hitch wire harness

wire harness clips

wire harness radio

3-wire camshaft position sensor wiring harness

5-wire blower motor harness connector

ls wire harness

painless performance wire harness

wire harness manufacturing

custom wire harness

melted caused by fire wire harness