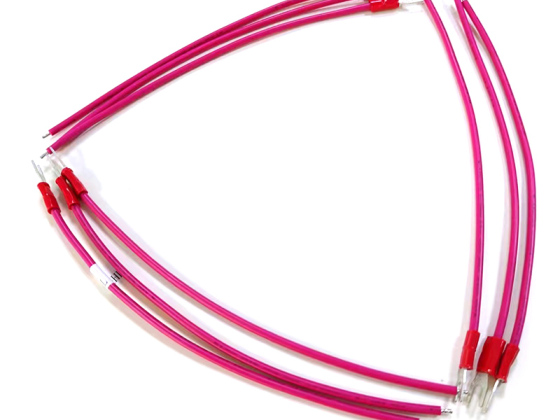

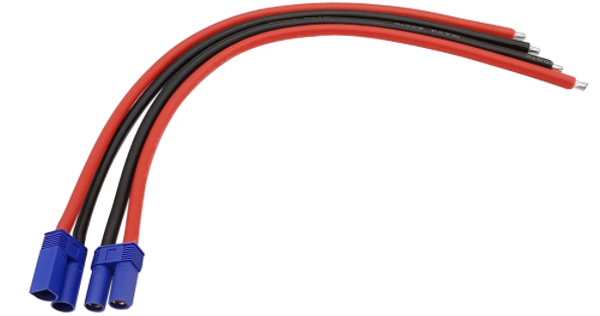

EC5 Cable

Our EC5 charger leads are designed and manufactured using high-quality materials. This is to ensure our clients enjoy nothing but the best quality connections each time they charge their battery—a whole new reason why you need to contact us for all your EC5 cable needs.

Our EC5 cables have high current endurance and can protect your toys from short circuits and outside influences.

EC5 cables provide a strong and reliable connection with a reusable connector end design that can be inserted and removed from the housing multiple times.

And these EC5 battery cables are specially designed for connecting batteries and ESCs and are perfectly suitable for various remote control car models, aircraft models, ship models, etc.

- Information

EC5 Cable: The Ultimate Guide

OEM ODM wiring Harness Factory

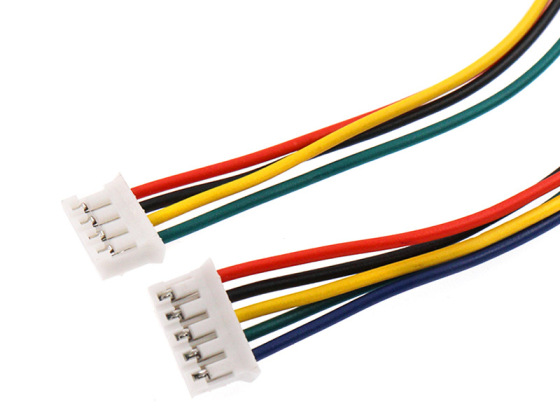

Customized Male to Female Wire Harness

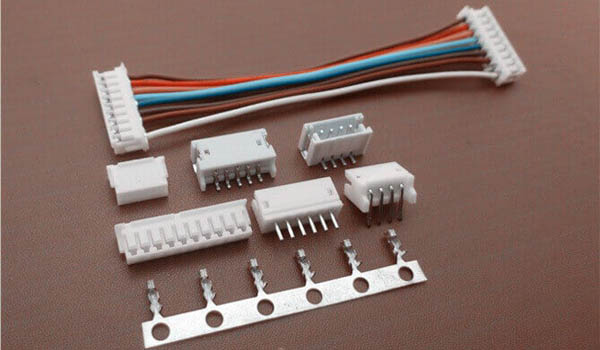

Terminal wire 1.25 air docking Cable Harness

Terminal Wire Harness Kit manufacturer

Custom Cable Assembly

EC5 are advanced version connectors of the EC3 connectors. An EC5 connector is an abbreviation of an E-flite Connector 5mm connector connecting other connectors and electric power accessories. The upgrading of the EC3 to EC5 connectors also led to the upgrading of the EC5 cables for compatibility. Using a bigger battery on your vehicle will require you to use an EC5 connector and cable to improve its performance.

EC5 cable transmits higher voltage than EC3 cable, thus, increasing your car’s power. An EC5 cable works best with accessories that use battery power. An EC5 charge cable is connected to an EC5 connector and acts as a power transmission medium.

EC5 Vs. EC3 Charging Cable

EC5 and EC3 cables have similar features but differ in various aspects. Some of the cables’ similarities are;

Both cables are efficient when using battery power

They are made from conductors, commonly copper, a great electricity conductor.

They are greatly flexible as they can be folded with ease.

They have insulations colored red and black (or yellow)

EC5 and EC3 cables’ differences are;

EC3 cables

EC3 charging cables are applicable for smaller vehicles.

The cables have connectors 17mm wide and 25 mm long.

An EC3 cable is approximately 30cm long.

The cable can handle the energy of about 90Amps, but a majority of the cable’s operations require 50-60 Amps.

EC5 Cables

An EC5 cable is meant for bigger operations, for example, fast racing cars and driving bashers.

The cable has a connector 34mm long, and 20 mm long but varies from one model to another.

The cable’s length ranges from 30-35cm

The cable handles operations requiring 120Amps

Is a JST ZH cable connector compatible with ZR insulations connectors?

The answer is simply yes. This is since a ZH cable connector features a shrouded header that can easily be used as a ZR IDC style cable connector or a ZH crimp style cable connector. The shrouded feature of this connector, therefore, makes it possible to use the connector interchangeably without the need for a replacement.

Applications of EC5 Charging Cable

An EC5 cable is used in bigger vehicles like fast racing cars and driving bashers. The cable is efficient for such an operation due to its ability to transmit higher voltage. It can manage to work sufficiently with bigger and/or multiple batteries with ease. The cable’s ability to transmit more energy ensures a fast racing vehicle reaches greater acceleration within a short span.

The EC5 cable has a robust insulating jacket that prevents current flow interference. Also, the insulation makes the cable flexible and protects the cable even at extremely high temperatures.

Significances of an EC5 Charge Cable

An EC5 cable efficiently improves the power supply for higher operations to increase performance. This cable has a variety of advantages enabling it to serve its purposes efficiently;

The cable has PVC insulation- highly resistant to extremely harsh conditions (abrasion, high-temperature, chemical corrosions)

Efficient in transmitting electric current with high voltage

Highly flexible and applicable in limited spaces.

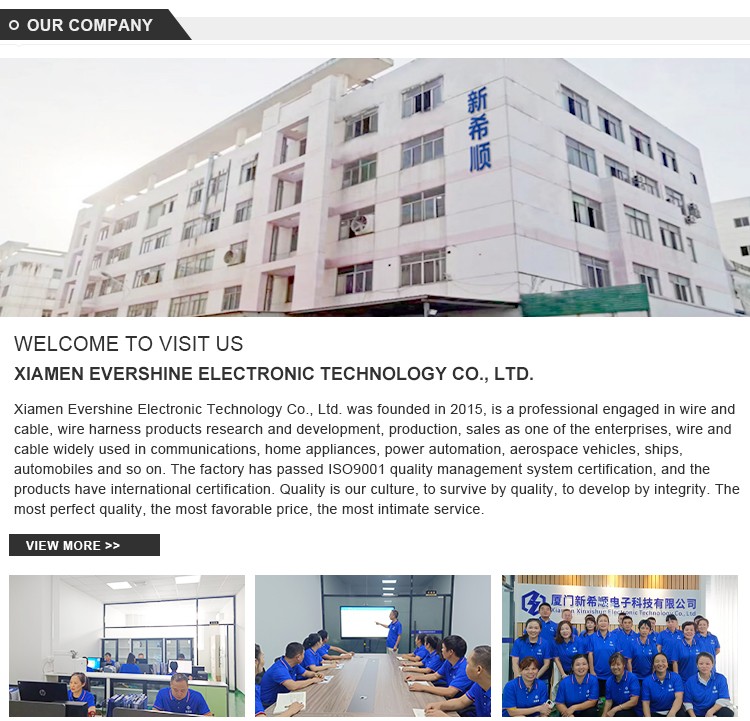

Company Information:

Xiamen Evershine Electronic Technology Co., Ltd. was founded in 2015, is a professional engaged in wire and cable, wire harness products research and development, production, sales as one of the enterprises, wire and cable widely used in communications, home appliances, power automation, aerospace vehicles, ships, automobiles and so on.

The factory has passed ISO9001 quality management system certification, and the products have international certification. Quality is our culture, to survive by quality, to develop by integrity. The most perfect quality, the most favorable price, the most intimate service.

Now we mainly offer you the wires products list as various electronic wire harness wiring design, custom vehicle wiring harness, home appliance wire harness, customized industrial wire harness, computer wire harness, over-molded cable connectors, terminal block connectors, power cable types, Products have been widely used in office equipment, communications, household appliances, industrial automation, automobile, etc.

What is Cable Harness?

Cable assemblies are groups of cables which are arranged into a single unit for a particular purpose. Cable assemblies are also referred to as cable harnesses or wiring looms.

These cables are grouped together in precisely the required length and orientation in order to make installation easier and quicker. They often include different cable constructions, as well as varying sizes, colours and lengths depending on the application. The assemblies may be compiled with a sleeve applied overall, or taped or bound with cable ties to help group the cables together, protecting them and making them more compact to save space. Depending on the application the assembly may be fitted with various terminations, including plug or socket arrangements.

What is the Wire Harness Assembly Process?

Wire Preparation. Cut the wires to the required lengths based on the design specifications.

.Crimping or Soldering.

Terminal Assembly.

Harness Routing and Bundling.

Testing and Inspection.

Protective Covering

.Labeling and Marking.

Final Quality Check and Packaging.

Where are wiring harnesses used?

Wire harnesses are everywhere — under the hood of every car and truck on the road, and in every plane, jet, and rocket in the sky. Wire harnesses are also referred to as cable harnesses or cable assemblies. These terms all describe a systematic set of cables or wires bundled to form an integrated unit.

wire harness assembly

wire harness connectors

engine wire harness

wire harness kit

wire harness for car

car stereo wire harness

harness wire for car stereo

Metra wire harness

radio wire harness

trailer hitch wire harness

wire harness clips

wire harness radio

3-wire camshaft position sensor wiring harness

5-wire blower motor harness connector

ls wire harness

painless performance wire harness

wire harness manufacturing

custom wire harness

melted caused by fire wire harness