9V Battery Cable Connector

9-volt battery cable features lots of applications. It features a connector lead that is color-coded for easy connections. These colors include red and black. The 9V battery cord can also be applied in different experiments and hoppy applications, a reason why you need to have a better understanding before choosing one.

Evershine offers a wide range of quality 9-volt battery cords with I or T-type connectors, to meet the needs of today’s equipment. Aside from that, we can custom manufacture the 9-volt cables based on your required specifications. Your custom labels can be printed on the 9V battery cables.

- Evershine

- Xiamen

- 7~15 days

- 100000pcs/month

- Information

9V battery connector

OEM ODM wiring Harness Factory

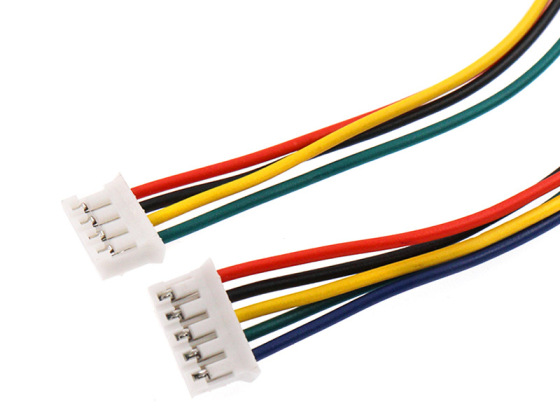

Customized Male to Female Wire Harness

Terminal wire 1.25 air docking Cable Harness

Terminal Wire Harness Kit manufacturer

Custom Cable Assembly

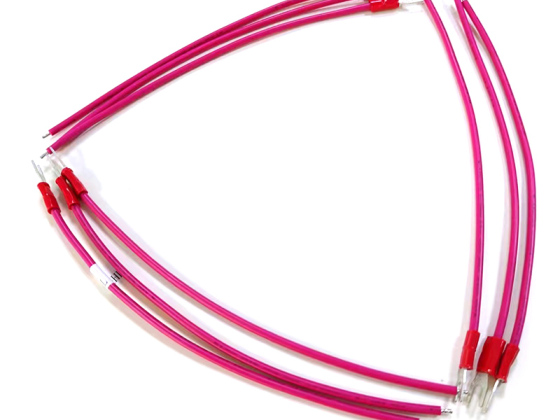

This is the 9V battery connector for use with 9V high wattage batteries. This has a standard color convention for the two wires, where black is ground and red is a positive voltage. The wire for the battery connector is a copper wire. This battery connector is very convenient and avoids the extra effort of connecting the battery to any electronic device or project.

The strap consists of nickel-plated brass contacts and two PVC-insulated copper wire conductors. The ends of the wires are stripped to ensure easy connections in breadboards and PCBs.

9V Battery Cable: The Ultimate Guide

This piece will take you through a 9V battery cable assembly, including its features and applications.

Why do you need a 9V battery cable?

The 9V battery wires’ original purpose was to transistor radios way back in the 1950s. At this time, the cable expectation was to deliver a 22.5 V. However, with the reduction in transistor radio’s power demand, so did the battery’s power output until it was standardized to the 1604 ANSI global standards.

Currently, the 9V wire harness has a broader application from smoke alarms, speakers, and even the industry meters. Regardless of these changes, these batteries still can’t withstand the diverse applications in which they are currently being used. Here are two main applications of 9-volt battery wiring harness.

Safety Devices

According to fire protection departments across the globe, dead batteries accounts for 24 percent of smoke alarm failures by 2015. Since the main purpose of a smoke alarm is to easily alert users of the potential danger of a just started fire, the battery needs to function.

Safety devices like sensors, telematics, emergency bacon, and metering gadgets are normally idle for quite some time, especially within harsh environs calling the battery cable infrequently. To maximize efficiency and safety, it’s wise to use a 9V battery cable as it can withstand harsh environs while providing a more extended life span functionality of up to 10 years.

9 volt battery wiring harness can operate even in areas that experience a -40C to 60C and still maintain optimum performance.

Medical Appliances

This is undoubtedly one of the fields where proper consideration has to be outlined when choosing a 9V battery cable. The medical field environment normally experiences lots of sensitive electromagnetic interferences. This includes patient data recorders, surgical lighting, and medical instruments.

Here, selecting a 9-volt battery cable involves considerations such as high pulse features with a non-magnetic design. The battery cable’s high pulse rate ensures a consistent power supply to the most demanding gadgets. This can easily be achieved by using a customized 9V battery cable with lower internal impedance, which makes it possible to supply higher power outputs with stable voltage.

Summing Up

9V battery cable remains a better option for a different application. However, it’s important to ensure that your projects go hand in hand with the 9V battery cable. At Eco Cables, we’re always ready to provide a helping hand as far as 9 volt wiring harness customization is concerned.

What are the features of 9V battery cable?

These rigid yet vital battery snaps for the 9V batteries are well-known battery snaps that are considered solid and long-lasting. The battery snaps feature two leads, with the red lead being the positive one while the black lead is the negative wire. These snaps are also designed to perfectly snap onto any of the standard 9V battery lead terminal ends. Some of the common features associated with this battery snap include:

Compatibility with standard 9V batteries

Features a positive (red wire) and negative (black wire)

Offered in a package of five

Company Information:

Xiamen Evershine Electronic Technology Co., Ltd. was founded in 2015, is a professional engaged in wire and cable, wire harness products research and development, production, sales as one of the enterprises, wire and cable widely used in communications, home appliances, power automation, aerospace vehicles, ships, automobiles and so on.

The factory has passed ISO9001 quality management system certification, and the products have international certification. Quality is our culture, to survive by quality, to develop by integrity. The most perfect quality, the most favorable price, the most intimate service.

Now we mainly offer you the wires products list as various electronic wire harness wiring design, custom vehicle wiring harness, home appliance wire harness, customized industrial wire harness, computer wire harness, over-molded cable connectors, terminal block connectors, power cable types, Products have been widely used in office equipment, communications, household appliances, industrial automation, automobile, etc.

What is Cable Harness?

Cable assemblies are groups of cables which are arranged into a single unit for a particular purpose. Cable assemblies are also referred to as cable harnesses or wiring looms.

These cables are grouped together in precisely the required length and orientation in order to make installation easier and quicker. They often include different cable constructions, as well as varying sizes, colours and lengths depending on the application. The assemblies may be compiled with a sleeve applied overall, or taped or bound with cable ties to help group the cables together, protecting them and making them more compact to save space. Depending on the application the assembly may be fitted with various terminations, including plug or socket arrangements.

What is the Wire Harness Assembly Process?

Wire Preparation. Cut the wires to the required lengths based on the design specifications.

.Crimping or Soldering.

Terminal Assembly.

Harness Routing and Bundling.

Testing and Inspection.

Protective Covering

.Labeling and Marking.

Final Quality Check and Packaging.

Where are wiring harnesses used?

Wire harnesses are everywhere — under the hood of every car and truck on the road, and in every plane, jet, and rocket in the sky. Wire harnesses are also referred to as cable harnesses or cable assemblies. These terms all describe a systematic set of cables or wires bundled to form an integrated unit.

wire harness assembly

wire harness connectors

engine wire harness

wire harness kit

wire harness for car

car stereo wire harness

harness wire for car stereo

Metra wire harness

radio wire harness

trailer hitch wire harness

wire harness clips

wire harness radio

3-wire camshaft position sensor wiring harness

5-wire blower motor harness connector

ls wire harness

painless performance wire harness

wire harness manufacturing

custom wire harness

melted caused by fire wire harness