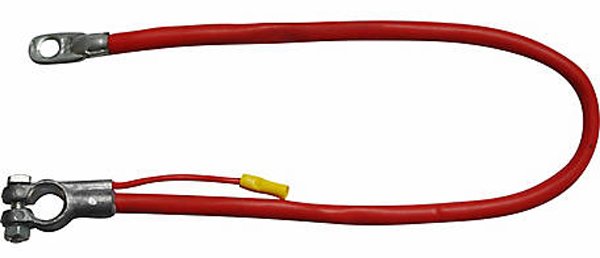

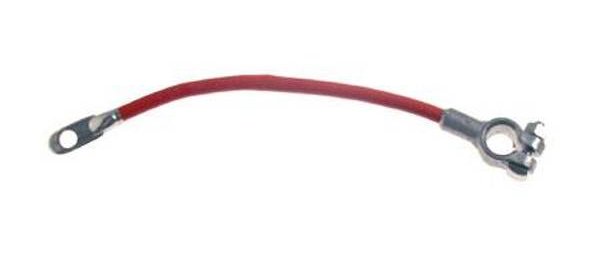

2 Gauge Battery Cable

This series of high quality battery cables is tinned copper stranded wire, maximum protection against corrosion and electrolysis.

Ultra-flexible strands resist vibration and bending fatigue, and premium vinyl insulation resists saltwater, battery acid, oil, gas, and ultraviolet light.

The cell lugs are made of premium tin plated and UL rated double wall shrink tube waterproof design.

Exceeds all UL 1426, USCG Charter, CSA and ABYC standards, rated at 600V.

- Evershine

- Xiamen

- 7~15 days

- 100000pcs/month

- Information

2 Gauge Battery Cable

OEM ODM wiring Harness Factory

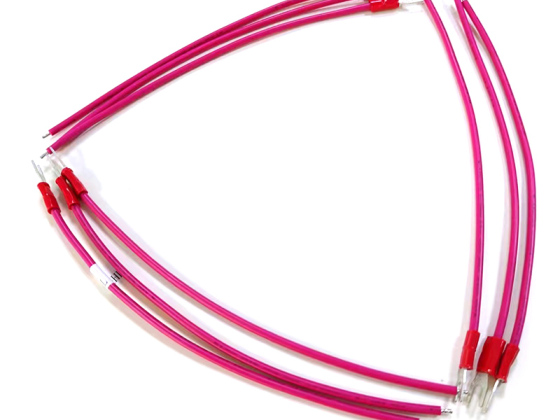

Customized Male to Female Wire Harness

Terminal wire 1.25 air docking Cable Harness

Terminal Wire Harness Kit manufacturer

Custom Cable Assembly

2 gauge battery features tinned copper stranding for maximum protection against corrosion and electrolysis. The ultra-flexible stranding resists fatigue due to vibration and flexing, and the premium vinyl insulation resists attack by saltwater, battery acid, oil, gas, and UV light.

100% Made in China.

Highly flexible industrial grade electrical cable.

Approved for up to 600 volts, -50°C to +105°C (-58°F to +221°F).

Rated as dual-use for welding or battery installation applications.

2 Gauge Battery Cable Explained

In the modern world, automobiles have become a necessity. It has become quite difficult to operate your daily activities without having a car. Well, for these automobiles to be useful and serve the right purpose, they need a 2 gauge battery cable. This means it’s an essential component that should never be overlooked.

The problem is that many people find it hard to tell the difference between a 2 gauge battery cable assemblies from the other cables. The 2 AWG battery wire is perfect for a broad range of automobiles, including small and big cars, RV trailers, and watercraft. Owing to this, don’t you think it’s wise to learn everything there is on a 2 gauge battery cable? Well, read on to have a better understanding.

What is the meaning of a 2 gauge battery cable?

Battery cables have been in existence for quite some time. However, the advancement brought forth by technology and time has made these cables vital. With many people owning cars, the first thing you see when you open your car engine component is heavy-duty wires which are perfectly covered with thick insulation material and then attached to a battery.

Therefore, battery cable refers to a thick but heavy-duty wire attached to the vehicle battery. You can have a 2 gauge battery cable which leads to another question.

What is a 2 gauge battery cable?

Overall, battery wires are set apart by factoring in their sizes using the AWG standard.

What does this imply on the 2 gauge battery cable?

This rule indicates that the higher the AWG number, the smaller the wire. It’s, therefore, true to conclude that a 2 gauge battery cable wire is larger than a 12 gauge battery cable wire.

What Diameter does 2 gauge battery cable has?

Here the diameter refers to the straight line passing the circular object center. Since cables feature a circular shape, it’s clear that the cable diameter refers to the straight line that passes through the cable center. So what is the diameter of a 2 gauge battery cable?

As earlier mentioned, 2 gauge battery cables play a vital role in different automobiles, including boats and cars, and any auto that uses a 12 and 24 V electrical system. To have an easy time withstanding such a voltage, the cable has to be covered with durable thick insulation and features a higher temperature resistance.

The 2 gauge battery cable diameter is around 10.2mm. This is equivalent to almost 0.4 inches. Apart from the cable’s diameter, the cross-sectional area and the conductor resistance also have an essential role in the wires carrying current capacity.

What is the maximum amps handled by a 2 gauge battery cable?

Under normal temperatures, the 2 gauge battery cable wire will feature 150 amperes capacity. However, this value is subject to change depending on different aspects like the cable’s length and ambient temperature.

Due to the cable’s current carrying capacity can be used for small cars, golf carts, and solar cells. However, when applying this cable within a DC power system, important consideration has to be put on the overall length of both the negative and positive cable.

Company Information:

Xiamen Evershine Electronic Technology Co., Ltd. was founded in 2015, is a professional engaged in wire and cable, wire harness products research and development, production, sales as one of the enterprises, wire and cable widely used in communications, home appliances, power automation, aerospace vehicles, ships, automobiles and so on.

The factory has passed ISO9001 quality management system certification, and the products have international certification. Quality is our culture, to survive by quality, to develop by integrity. The most perfect quality, the most favorable price, the most intimate service.

Now we mainly offer you the wires products list as various electronic wire harness wiring design, custom vehicle wiring harness, home appliance wire harness, customized industrial wire harness, computer wire harness, over-molded cable connectors, terminal block connectors, power cable types, Products have been widely used in office equipment, communications, household appliances, industrial automation, automobile, etc.

What is Cable Harness?

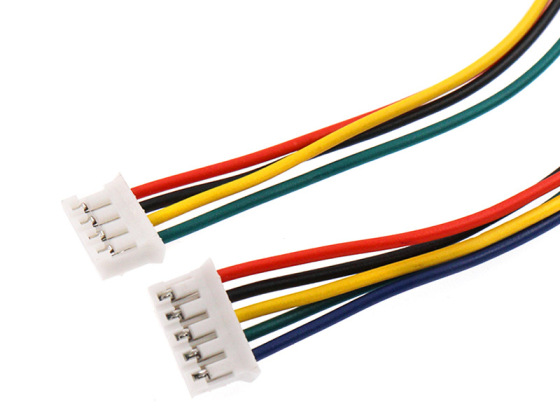

Cable assemblies are groups of cables which are arranged into a single unit for a particular purpose. Cable assemblies are also referred to as cable harnesses or wiring looms.

These cables are grouped together in precisely the required length and orientation in order to make installation easier and quicker. They often include different cable constructions, as well as varying sizes, colours and lengths depending on the application. The assemblies may be compiled with a sleeve applied overall, or taped or bound with cable ties to help group the cables together, protecting them and making them more compact to save space. Depending on the application the assembly may be fitted with various terminations, including plug or socket arrangements.

What is the Wire Harness Assembly Process?

Wire Preparation. Cut the wires to the required lengths based on the design specifications.

.Crimping or Soldering.

Terminal Assembly.

Harness Routing and Bundling.

Testing and Inspection.

Protective Covering

.Labeling and Marking.

Final Quality Check and Packaging.

Where are wiring harnesses used?

Wire harnesses are everywhere — under the hood of every car and truck on the road, and in every plane, jet, and rocket in the sky. Wire harnesses are also referred to as cable harnesses or cable assemblies. These terms all describe a systematic set of cables or wires bundled to form an integrated unit.

wire harness assembly

wire harness connectors

engine wire harness

wire harness kit

wire harness for car

car stereo wire harness

harness wire for car stereo

Metra wire harness

radio wire harness

trailer hitch wire harness

wire harness clips

wire harness radio

3-wire camshaft position sensor wiring harness

5-wire blower motor harness connector

ls wire harness

painless performance wire harness

wire harness manufacturing

custom wire harness

melted caused by fire wire harness