Wholesale 3-in-1 Fast Charger USB Type C Data Cables

Wholesale 3-in-1 Fast Charger USB Type C Data Cables manufacturer ,the convenient and portable three in one data cable fast charging cable can simultaneously meet the charging needs of various products,such as iphone.

It includes three interfaces: USB, Type-C, and Apple, with one wire and three uses. Usb Type C charging cable assembly

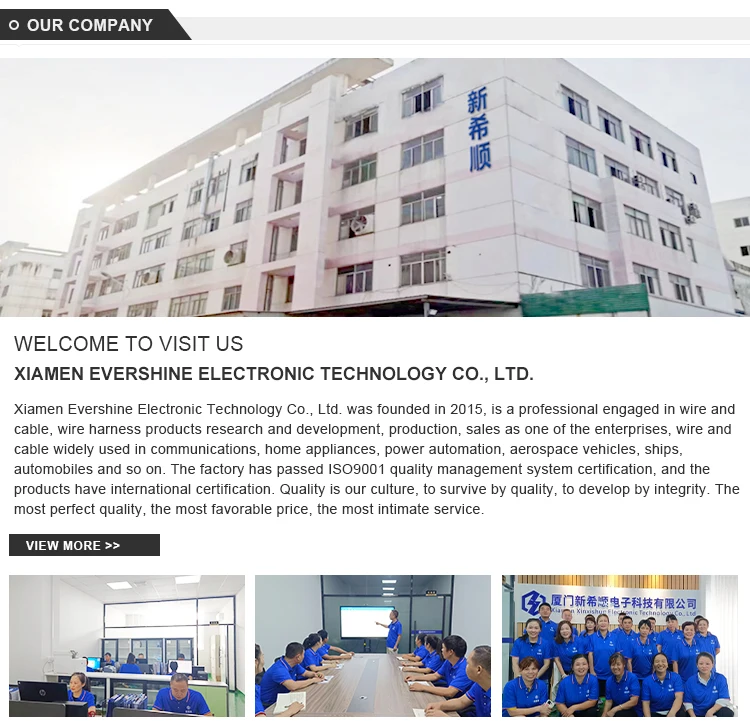

- Evershine

- Xiamen

- 7~15 days

- 100000pcs/month

- Information

Wholesale 3-in-1 Fast Charger USB Type C Data Cables manufacturer ,the convenient and portable three in one data cable fast charging cable can simultaneously meet the charging needs of various products,such as iphone.

It includes three interfaces: USB, Type-C, and Apple, with one wire and three uses. Usb Type C charging cable assembly

USB Cable 2.0

USB AM to Mini USB 5Pin

USB AM to USB AF

USB AM to Mirco USB

USB Cable spec: UL2725 1P+2C +Al +Braid

USB2.0 AM to Mini USB 5pin or Mirco USB

Connector: Copper shell or Iron Ni Plated

Cable spec: UL2725 1P + 2C+ Al +Braid

Cable AWG: AWG28 , AWG28 +AWG26 etc,can be done as your request

Jacket: PVC

Color: Black,Purple

USB cable 2.0

1.USB(AM)-USB(AM)

2.USB(AM)-USB(AF)Extension cable

3.USB(AM)-USB(BM)printer cable

Our Advantages:

Our Advantages:1. One-stop supply.

2. Leadtime is short: within 3~10days after products details confirmed.

3. High quality with price policy: We service many top customers . These customers strictly require in

products quality and company management system.All our products quality is same level. Price Policy:

We supply good price not only to end customer,but also same to trade company.

It's natural to have questions. Here are some qustions customs often ask us about our factory:

1. The Role of a Data Cable Manufacturer in the Modern Technological Landscape

Data cable manufacturers are essential players in today's technology-driven world. They are the architects behind the physical infrastructure that enables the transmission of data, which is the lifeblood of modern communication, commerce, and entertainment. From the ubiquitous Ethernet cables connecting computers to local networks to the fiber optic cables that power the internet backbone, these manufacturers provide the critical links that allow us to access information, collaborate remotely, and enjoy digital content. They work closely with technology companies, telecommunications providers, and infrastructure developers to design, produce, and test data cables that meet stringent performance and reliability standards. Their expertise is crucial for ensuring that data can be transmitted quickly, accurately, and securely, enabling the seamless operation of everything from smartphones and laptops to data centers and global communication networks. In essence, data cable manufacturers are the unsung heroes of the digital age, providing the foundation upon which our interconnected world is built.

2.how to choose a reliable Data Cable manufacturer in China?

Choosing a reliable data cable manufacturer in China requires careful research and due diligence. Start by defining your specific needs: cable type, performance requirements (bandwidth, speed), quantity, budget, and any necessary certifications (UL, RoHS). Next, research potential manufacturers online using platforms like Alibaba, Global Sources, and industry-specific directories. Look for manufacturers with a proven track record and years of experience.

Verify their certifications and compliance with international standards. Don't rely solely on website claims; request copies of their certifications and verify their authenticity with the issuing bodies. Check their quality control processes. A reliable manufacturer will have robust testing procedures and be willing to share their quality control documentation.

Request samples of their cables to assess their quality firsthand. Test the samples for performance and durability. Communicate clearly with the manufacturer about your requirements and expectations. Assess their responsiveness, communication skills, and willingness to address your concerns.

Consider visiting the manufacturer's factory for a physical audit. This allows you to assess their production capabilities, quality control processes, and overall professionalism. Finally, compare quotes from multiple manufacturers and consider not only the price but also the quality, service, and reputation. Choosing a reliable manufacturer requires a thorough evaluation process.

3. Key Capabilities and Services Offered by Data Cable Manufacturers

Data cable manufacturers offer a range of capabilities and services beyond simply producing cables. These include design and engineering, prototyping, testing, and supply chain management. Design services involve collaborating with clients to develop custom cable solutions that meet specific performance, size, and environmental requirements. Prototyping allows for the creation of sample cables for testing and validation before mass production. Manufacturing capabilities encompass wire drawing, insulation, twisting, shielding, jacketing, and connector assembly, utilizing both automated and manual processes. Testing services ensure that cables meet industry standards and customer specifications, including signal integrity testing, impedance testing, and environmental testing. Many manufacturers also offer supply chain management services, sourcing components, managing inventory, and providing just-in-time delivery to streamline their clients' operations. Some also offer value-added services such as cable labeling, custom packaging, and kitting. The breadth of these capabilities enables data cable manufacturers to act as strategic partners, providing comprehensive solutions from concept to delivery.

4. The Design and Engineering Process at a Data Cable Manufacturing Company

The design and engineering process at a data cable manufacturing company is a critical step that determines the cable's performance, reliability, and cost-effectiveness. It starts with a thorough understanding of the client's requirements, including data transmission speed, bandwidth, signal integrity, impedance, and environmental conditions. Engineers then create detailed cable designs using CAD software, specifying wire gauges, insulation materials, shielding configurations, and connector types. Simulation tools may be used to analyze signal integrity, impedance matching, and electromagnetic interference (EMI) performance. Design for Manufacturability (DFM) principles are applied to optimize the cable for efficient and cost-effective production. Prototyping is used to create sample cables for testing and validation. Once the design is finalized, detailed manufacturing instructions are generated, including wire cutting lists, twisting patterns, shielding procedures, and connector assembly specifications. The design and engineering process is iterative, with continuous refinement based on testing results and feedback from the manufacturing team.

5. Quality Control and Testing Procedures in Data Cable Manufacturing

Quality control and testing are paramount in data cable manufacturing to ensure that cables meet stringent performance and reliability requirements. Manufacturers implement rigorous procedures throughout the production process to identify and address any potential defects. Incoming materials are inspected for compliance with specifications, and in-process inspections are conducted at each stage of manufacturing, from wire drawing to connector attachment. Electrical testing includes continuity testing, impedance testing, signal integrity testing, and crosstalk testing. Mechanical testing includes tensile strength testing, flex testing, and vibration testing. Environmental testing simulates extreme temperatures, humidity, and vibration to assess the cable's durability. Automated testing equipment is used to perform comprehensive electrical tests and generate detailed reports. Statistical process control (SPC) is used to monitor and control the manufacturing process and identify any potential quality issues. These comprehensive measures guarantee that only high-quality data cables are shipped to customers.

6. The Importance of Certifications and Standards for Data Cable Manufacturers

Certifications and standards are vital for data cable manufacturers, ensuring product quality, safety, and interoperability. ISO 9001 certification demonstrates that a manufacturer has a robust quality management system. UL certification indicates that a cable meets Underwriters Laboratories' safety standards. TIA/EIA standards define performance requirements for various types of data cables, such as Cat5e, Cat6, and Cat6a. Compliance with these standards ensures that data cables meet minimum performance requirements and are compatible with various networking equipment. RoHS compliance restricts the use of hazardous substances in data cables. Certifications and standards provide assurance to customers that the data cables they purchase meet the highest levels of quality and safety. They also demonstrate a manufacturer's commitment to continuous improvement and adherence to best practices.

7. Automation and Technology in Data Cable Manufacturing

Automation and technology are transforming the data cable manufacturing industry, improving efficiency, reducing costs, and enhancing quality. Automated wire drawing machines precisely draw copper or aluminum wire to the required diameter. Automated insulation machines apply insulation to the wires with consistent thickness and uniformity. Automated twisting machines twist the insulated wires together according to precise patterns. Automated shielding machines apply shielding materials to protect the cables from electromagnetic interference (EMI). Automated jacketing machines extrude a protective jacket over the cable core. Automated connector assembly machines attach connectors to the cable ends with consistent force and accuracy. Automated testing equipment performs comprehensive electrical tests and generates detailed reports. These technologies enable manufacturers to produce complex data cables with tight tolerances and high precision.