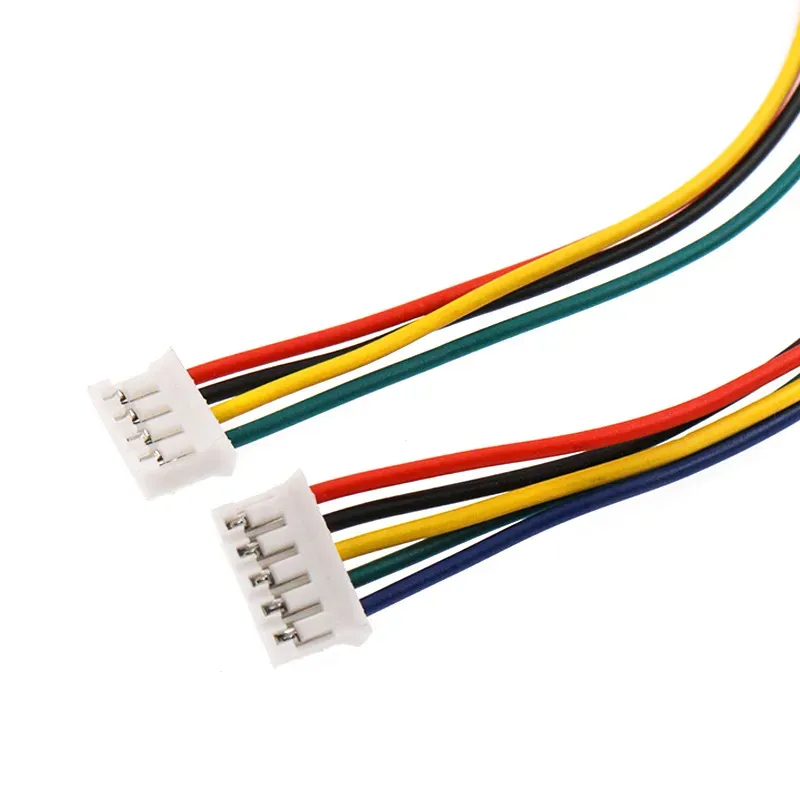

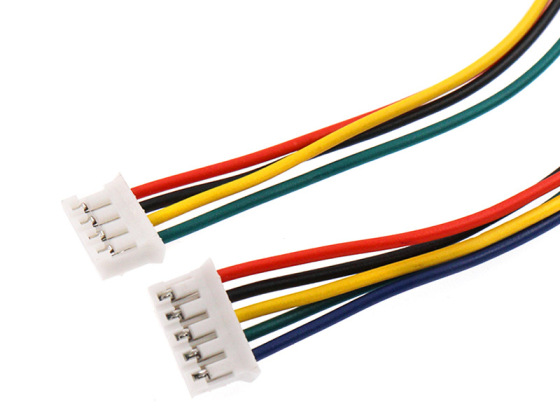

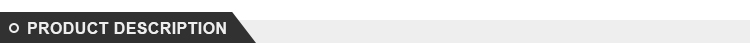

Manufacturer wholesale SH1.0mm terminal wire spacing 1.0mm wire to board wire harness

Manufacturer wholesale SH1.0mm terminal wire spacing 1.0mm wire to board wire harness, high quality best competitive price SH1.0mm Wire to board cable harness.For some devices that transmit signals, terminal wires are used to transmit various signals such as audio, video, etc.

- Evershine

- Xiamen

- 7~15 days

- 100000pcs/month

- Information

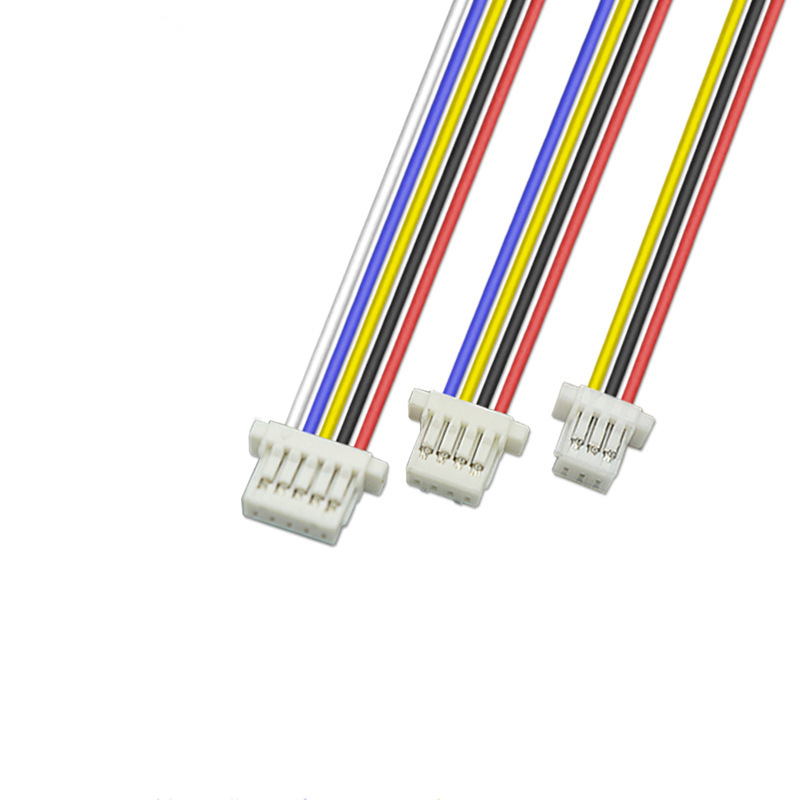

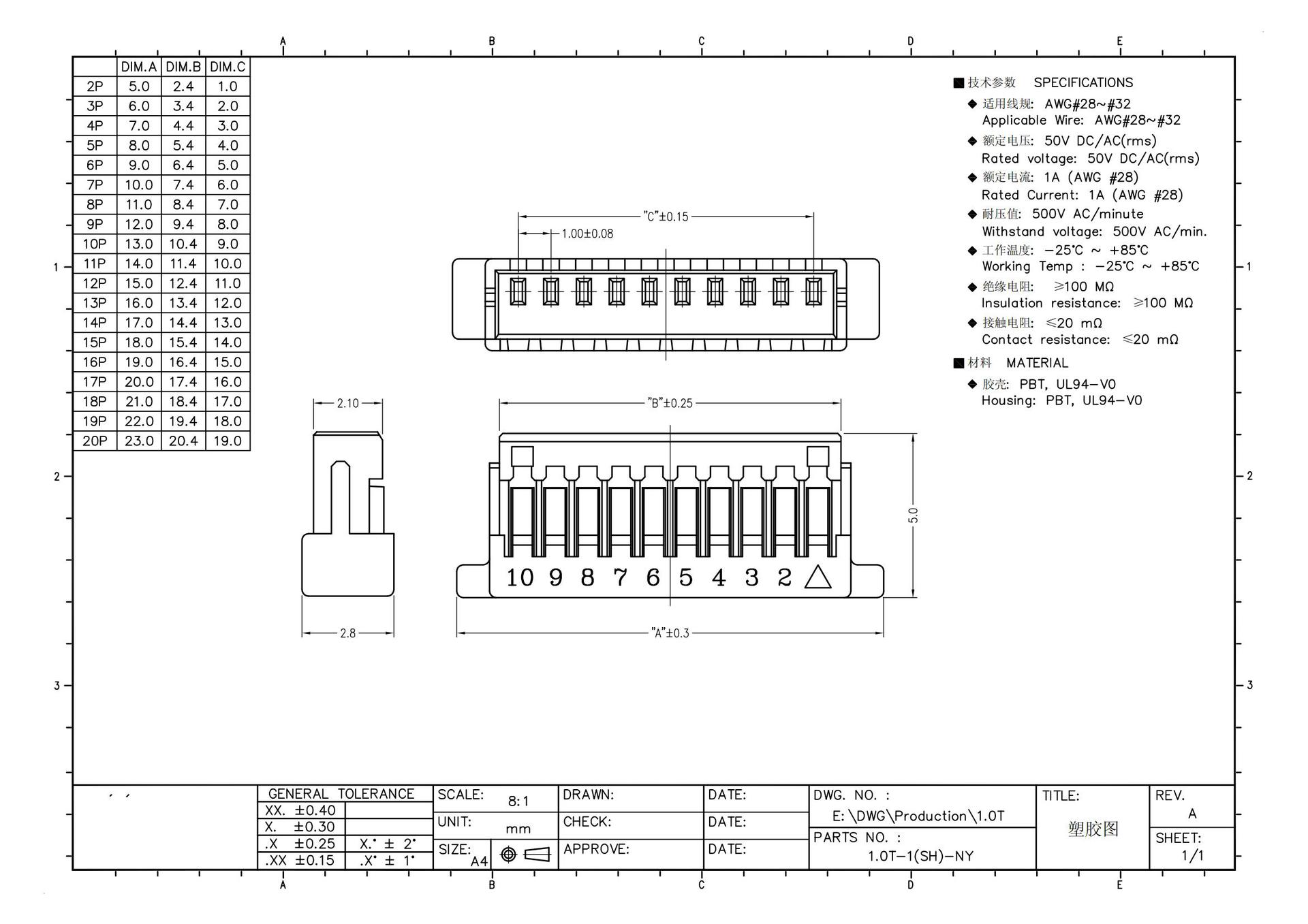

| Product name | SH 1.0 terminal wire to board wire harness |

| Length | customized |

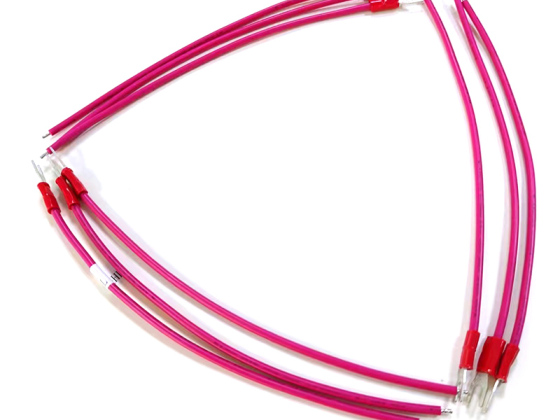

| Color | Black, Red or customized |

| Connector Type | JST SH 1.0 spacing |

| Certification | UL ISO CE |

| Other | Environmental PVC jacket |

| Can accept other cords customized? | Yes |

Why choosing US?

Xiamen Evershine Electronic Technology Co., Ltd. was founded in 2015, is a professional engaged in wire and cable, wire harness products research and development, production, sales as one of the enterprises, wire and cable widely used in communications, home appliances, power automation, aerospace vehicles, ships, automobiles and so on.

The factory has passed ISO9001 quality management system certification, and the products have international certification. Quality is our culture, to survive by quality, to develop by integrity. The most perfect quality, the most favorable price, the most intimate service.

Now we mainly offer you the wires products list as various electronic wire harness wiring design,

custom vehicle wiring harness, home appliance wire harness, customized industrial wire harness, computer wire harness, A wire harness, often referred to as a cable harness or wiring assembly, is a systematic and integrated arrangement of cables within an insulated material. The purpose of the assembly is to transmit signal or electrical power.Wire harness applications are used in nearly every conceivable household, commercial or industrial device - tools, equipment, machinery, hardware, household products - that transmits or relays electronic information or electrical power.

Details & Advantages

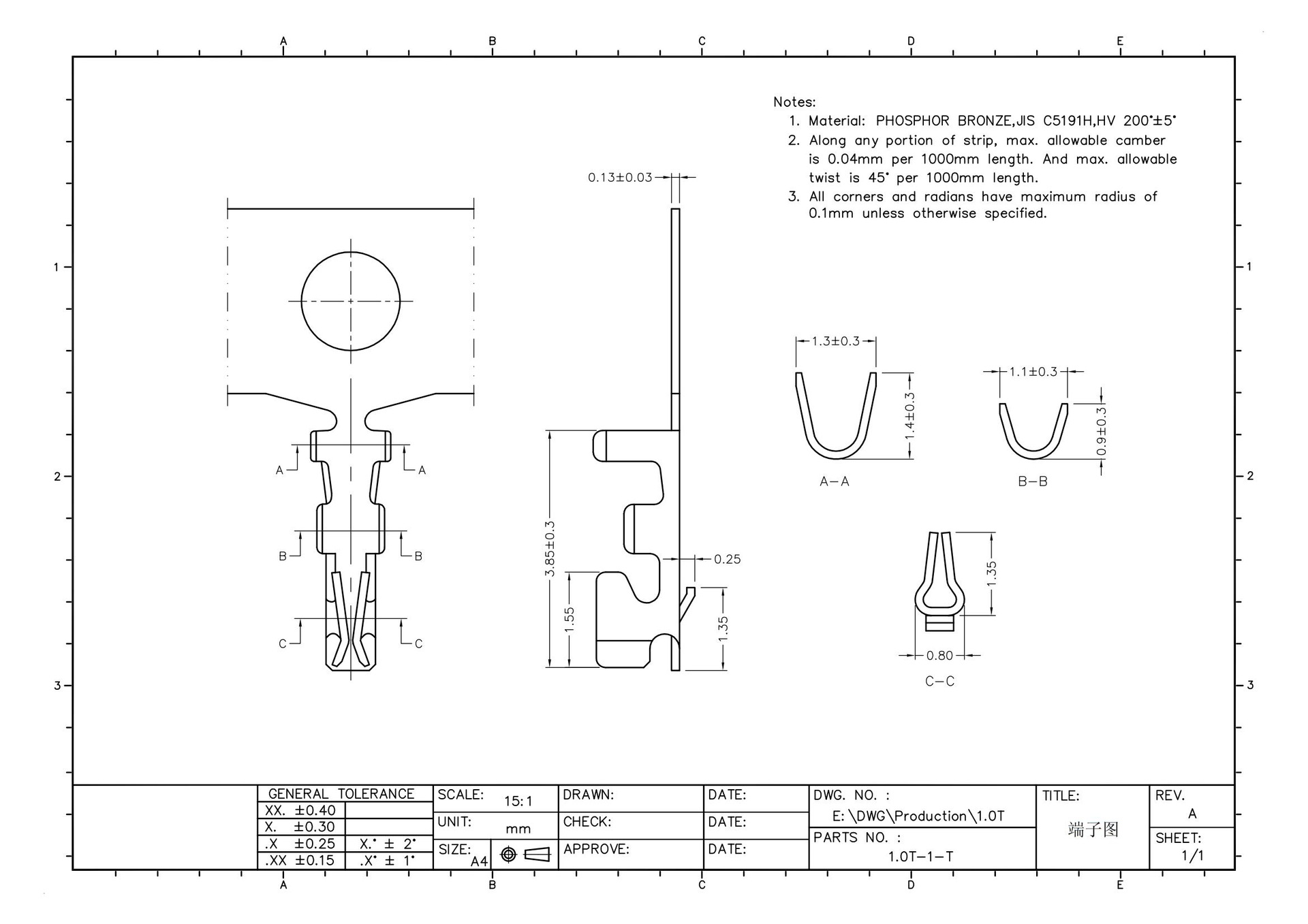

1. Pure copper core wires, stable current carrying

2. Comply with UL certification standard in excellent performance to keep power cord safety

3. Environmental materials with odorless, heat resistance, you will be assured when using our cords

4. Test reports before the shipment, quality assurance for every single cord cable

What You Might Want to Know:

1. What is a board wire harness?

A board wire harness is an organized assembly of wires and connectors designed specifically to connect electronic components on a circuit board or between multiple boards. It ensures reliable electrical connections, reduces wiring complexity, and improves maintenance. These harnesses are tailored to fit compact spaces and support efficient signal transmission while protecting wires from damage, interference, and wear.

2. How does a board wire harness differ from a standard wire harness?

Unlike standard wire harnesses used for general wiring, board wire harnesses are specifically designed for interconnecting printed circuit boards (PCBs) or components within electronic devices. They are often more compact, with precise connector placement and shorter cable lengths, optimized for high-density environments and sensitive electronic signals, ensuring minimal interference and maximum reliability.

3. What materials are used in board wire harnesses?

Board wire harnesses typically use fine-gauge copper wires for excellent conductivity and flexibility. Insulation materials like PVC, Teflon, or silicone protect against heat and electrical interference. Connectors are often made from durable plastics or metals with precise pins to ensure secure and stable connections on circuit boards. Shielding may be added to prevent electromagnetic interference in sensitive applications.

4. What industries commonly use board wire harnesses?

Board wire harnesses are widely used in electronics manufacturing, automotive control systems, aerospace avionics, medical devices, and telecommunications equipment. They provide organized and reliable connections between circuit boards, sensors, and control units, supporting complex electronic functions in compact spaces and harsh environments.

5. How do board wire harnesses improve electronic device reliability?

By providing secure, organized wiring paths with proper insulation and shielding, board wire harnesses reduce the risk of short circuits, signal loss, and mechanical damage. Their tailored design minimizes stress on connections and simplifies assembly and maintenance, enhancing overall device reliability and lifespan, especially in high-vibration or temperature-variable environments.

6. What design considerations are important for board wire harnesses?

Key design factors include wire gauge, insulation type, connector compatibility, cable length, and routing to avoid interference and mechanical strain. Designers must consider space constraints, thermal conditions, and signal integrity requirements. Proper labeling and modularity also facilitate assembly, testing, and future maintenance or upgrades.

7. How are board wire harnesses tested for quality?

Testing includes continuity checks, insulation resistance measurements, and functional testing of connectors. Environmental stress tests simulate temperature fluctuations, vibration, and humidity to ensure durability. Visual inspections verify assembly accuracy, while electrical tests confirm signal integrity and absence of shorts or open circuits, ensuring compliance with industry standards.

8. What role do connectors play in board wire harnesses?

Connectors in board wire harnesses provide secure, precise interfaces between wires and circuit boards. They ensure reliable electrical contact, ease of assembly, and resistance to mechanical stress. Connector types vary based on pin count, pitch, and locking mechanisms, tailored to the application’s electrical and mechanical requirements.

9. How does miniaturization affect board wire harness design?

As electronic devices become smaller, board wire harnesses must be more compact and flexible without compromising performance. Miniaturization demands thinner wires, smaller connectors, and efficient routing to fit limited space while maintaining signal integrity. This challenges designers to balance size, durability, and electrical performance.

10. What future trends are shaping board wire harness technology?

Future trends include the use of advanced materials for lighter, more heat-resistant harnesses, integration with smart sensors for diagnostics, and automation in manufacturing for higher precision. Wireless interconnections may reduce harness complexity, while modular designs enhance scalability and repairability in evolving electronic systems.