- Home

- >

- Products

- >

- M6 Cable Assembly

- >

M6 Cable Assembly

M6 cable assembly is flexible and resistant to crushing, making it ideal for industrial environments and high-temperature applications. It is perfectly designed to be compatible with most fibers and connectors.

It consists of micro circular connectors that allow for large spacing. Furthermore, when installation is done in the circular connector area, it can provide a reach of the electric circuit many times than an interconnected device.

- Evershine

- Fujian, China

- 7-15days

- The monthly production capacity is 10 million

- Information

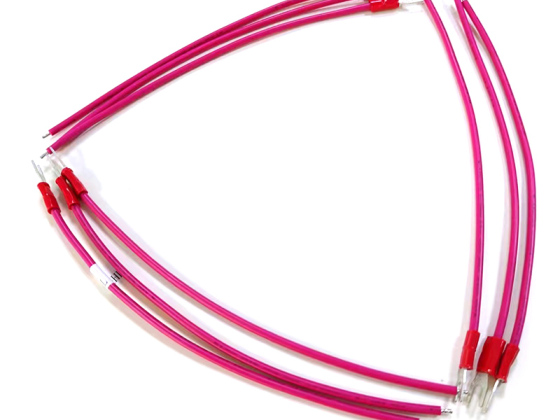

M6 Cconnector Cable Assembly

OEM ODM wiring Harness Factory

Customized Male to Female Wire Harness

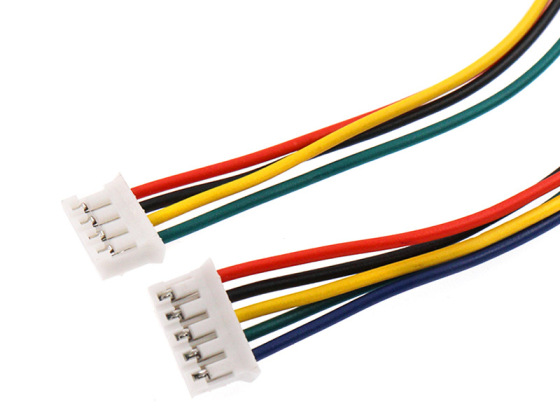

Terminal wire 1.25 air docking Cable Harness

Terminal Wire Harness Kit manufacturer

Custom Cable Assembly

M6 connector cable assembly is a cable using an M6connector.

M6 connector cable assembly is flexible and resistant to crushing, making it ideal for industrial environments and high-temperature applications. lt is perfectly designed to be compatible with most fibers and connectors.

It consists of micro circular connectors that allow for large spacing. Furthermore, when installation is done in the circular connector area, it can provide a more reliable electric circuit than an interconnected device.

M12 cable assemblies are available in 2, 3, 4, 5, 6Accept a wide range of wire diameters

PVC, PUR cable available

Meets lP67/lP68 waterproof requirements

What is an M6 Cable Assembly

A cable assembly consists of a collection of wires encased in a tube of material, usually PVC-insulated. Depending on the applications, they have different constructions and various sizes, colors, thicknesses, and lengths. They are fitted with other terminations that include plug or socket arrangements ,depending on the applications used. An example isan M6 Cable Assembly.

M6 cable assembly is designed in a snap-in series and consists of a range of connectors with different thickness sizes of approximately 8.5mm. This design allows ease of connection and disconnection and provides environmental sealing. Also, the cable assembly can be used within small spaces, optimizing areas.

Reasons of the M12 Connector Cable Assembly Popular

M6 cable assemblies are used in mass production to save time during the machine and equipment installation process, especially for a singular manufactured unit. The M6 cable assembly is standard in the automotive industry and electronic equipment.

M6 cable assemblies have a range of small, substantial, and environmentally sealed connectors, making them ideal for indoor and outdoor use, especially in situations requiring interconnection systems. However, harsher environments require an M6cable assembly that is sealed to the equipment, such as signs, address systems, LED screens, and lighting.

Each M6 cable has various ranges of connectors and terminals that are used extensively in controlling input or output data and electric current flow efficiently and effectively.

Design of an M6 Cable Assembly

The M6 cable assembly uses a PVC covering that provides security and protection. Also, the cable assembly has an approximate maximum current rating of 15A. M6 cable assemblies are best known to operate at a minimum temperature of -40 degrees Celsius and a maximum of 80 degrees Celsius.

Most M6 cable assemblies have an Insulation resistance of 2100M0and a Contact resistance of <5m(. Additionally, they consist of connector contacts that are brass and gold-plated and have a thickness of between 6mm and 8 mm, approximately.

Furthermore, it has solder or pre-wire termination and can easily fit a6.1 mm cut-out Fits 6.lmm cut-out.

Benefits of an M6 Cable Assembly

M6 cable assembly is flexible and resistant to crushing, making it ideal for industrial environments and high-temperature applications. It is perfectly designed to be compatible with most fibers and connectors.

It consists of micro circular connectors that allow for large spacing. Furthermore, when installation is done in the circular connector area, it can provide a reach of the electric circuit many times than an interconnected device.

In addition, the connectors allow good contact and connections with the equipment during installation, resulting in reliable operations. Also. The M6 cable assembly design is easy to maintain and service. They are suitably portable and easy to carry because of their light nature. In addition, M6 cable assemblies are cost-effective and easily affordable.

The quality of an M6 cable assembly is among the few things that can satisfy the user; therefore, careful selection of the product will be vital in achieving the overall benefits. Also, since many brands of M6 cable assemblies are in the market, the performance quality may differ for each application. When the quality is okay, users can be more satisfied.

Related Product

M6 connector cable assembly

M6 connector cable assembly

M6 connector cable assembly

Company Information:

Xiamen Evershine Electronic Technology Co., Ltd. was founded in 2015, is a professional engaged in wire and cable, wire harness products research and development, production, sales as one of the enterprises, wire and cable widely used in communications, home appliances, power automation, aerospace vehicles, ships, automobiles and so on.

The factory has passed ISO9001 quality management system certification, and the products have international certification. Quality is our culture, to survive by quality, to develop by integrity. The most perfect quality, the most favorable price, the most intimate service.

Now we mainly offer you the wires products list as various electronic wire harness wiring design, custom vehicle wiring harness, home appliance wire harness, customized industrial wire harness, computer wire harness, over-molded cable connectors, terminal block connectors, power cable types, Products have been widely used in office equipment, communications, household appliances, industrial automation, automobile, etc.

What is Cable Harness?

Cable assemblies are groups of cables which are arranged into a single unit for a particular purpose. Cable assemblies are also referred to as cable harnesses or wiring looms.

These cables are grouped together in precisely the required length and orientation in order to make installation easier and quicker. They often include different cable constructions, as well as varying sizes, colours and lengths depending on the application. The assemblies may be compiled with a sleeve applied overall, or taped or bound with cable ties to help group the cables together, protecting them and making them more compact to save space. Depending on the application the assembly may be fitted with various terminations, including plug or socket arrangements.

What is the Wire Harness Assembly Process?

Wire Preparation. Cut the wires to the required lengths based on the design specifications.

.Crimping or Soldering.

Terminal Assembly.

Harness Routing and Bundling.

Testing and Inspection.

Protective Covering

.Labeling and Marking.

Final Quality Check and Packaging.

Where are wiring harnesses used?

Wire harnesses are everywhere — under the hood of every car and truck on the road, and in every plane, jet, and rocket in the sky. Wire harnesses are also referred to as cable harnesses or cable assemblies. These terms all describe a systematic set of cables or wires bundled to form an integrated unit.

wire harness assembly

wire harness connectors

engine wire harness

wire harness kit

wire harness for car

car stereo wire harness

harness wire for car stereo

Metra wire harness

radio wire harness

trailer hitch wire harness

wire harness clips

wire harness radio

3-wire camshaft position sensor wiring harness

5-wire blower motor harness connector

ls wire harness

painless performance wire harness

wire harness manufacturing

custom wire harness

melted caused by fire wire harness