Inverter Battery Cable

Inverter battery connection cables are famous for their suitability for auto motors, appliances, and electronics use. Also, most have attached battery connectors that are reliable during installation.

Additionally, the inverter battery wire conductor is supported by copper and is PVC insulated to reduce corrosions caused by electric currents. Also, they have an extra flexible usage performance, are well resistant to oil, heat, and flame, and are convenient for use.

Anyone interested in using the inverter battery connection cables should consider the excellent quality before purchase. Features and specifications of the commodity are vital in ensuring that the overall performance is good. Moreover, the item and flexible nature make them a great thing in the electronic field. Contact us for more info about power inverter battery cables. Our team is available 24/7 to serve you.

- Information

Inverter Battery Cable

OEM ODM wiring Harness Factory

Customized Male to Female Wire Harness

Terminal wire 1.25 air docking Cable Harness

Terminal Wire Harness Kit manufacturer

Custom Cable Assembly

An inverter battery cable is a power electronic wire that changes direct current to alternating current in a battery. These cables are used to power electrical applications with high winds and voltages.

Moreover, they are built to be applied between a battery bank and an inverter cable.

Power inverter battery cables are also suitable for transformers, controls, and electronic circuits. They can be applied as battery charger cables and power hookup cables. In other cases, some are approved for both internal and external wiring of appliances.

LOW MOQ 50pcs accepted

The prototype is available, lead time: 1-3 days

Types of Inverter Battery Cable

Manufactured in various shapes and sizes, this Power inverter battery cable is classified according to the power ratings used during application.

The 4 American Wire Gauge Battery Cable

They are primarily used on power inverters with a high rating power of 1500watts. Moreover, this type of inverter battery connection cable is used on different power inverters that generate a power watt of between 900- 1200watts.

The 1/0 American Wire Gauge Battery Cables

This battery cable applies to power inverters with a power rating of 3500 watts. Furthermore, watt-inverters with a power rating ranging from 2000 to 3500 watts are effectively operational using this power inverter battery cable. In addition, they are widely used with 200 and 300ANL fuses and fuse kits.

The 4/0 American Wire Gauge Battery Cables

Applicable to 3500 watts rated power inverters and mainly used to power inverters with a higher power rating ranging from 4000 to 12000 watts. Furthermore, these inverter battery connection cables are used together with 500 ANL fuse kits.

Features and Specifications of Inverter Battery Cable

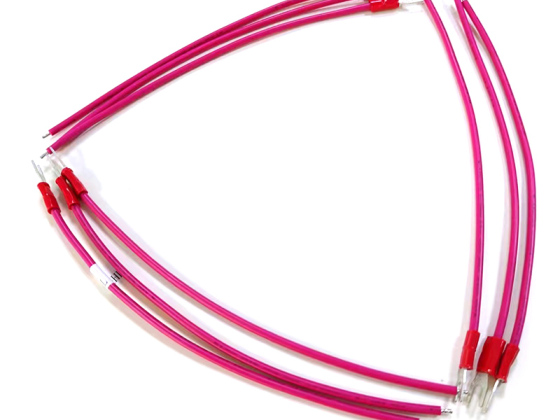

Inverter battery connection cables are pure copper. Furthermore, some have 8 feet of 10 gauge black grounding cable with lug connectors. The lug connectors are 5/16 inch or 3/8 inch long.

Also, they can come with extra battery cable lugs that allow attaching the appropriate stud size for the battery and inverter mounting terminals. In addition, the lug connectors allow for all possible combinations for inverters and batteries.

Moreover, the inverter battery cable lugs are pure copper with corrosion-resistant to tin coating. They operate at a 600volts maximum, temperature range of -55 Celsius to +125 Celsius; they are resistant to most solvents and fire-resistant.

Advantages of the Inverter Battery Cable

Inverter battery connection cables are famous for their suitability for auto motors, appliances, and electronics use. Also, most have attached battery connectors that are reliable during installation.

Additionally, the inverter battery wire conductor is supported by copper and is PVC insulated to reduce corrosions caused by electric currents. Also, they have an extra flexible usage performance, are well resistant to oil, heat, and flame, and are convenient for use.

Anyone interested in using the inverter battery connection cables should consider the excellent quality before purchase. Features and specifications of the commodity are vital in ensuring that the overall performance is good. Moreover, the item and flexible nature make them a great thing in the electronic field. Contact us for more info about power inverter battery cables. Our team is available 24/7 to serve you.

Company Information:

Xiamen Evershine Electronic Technology Co., Ltd. was founded in 2015, is a professional engaged in wire and cable, wire harness products research and development, production, sales as one of the enterprises, wire and cable widely used in communications, home appliances, power automation, aerospace vehicles, ships, automobiles and so on.

The factory has passed ISO9001 quality management system certification, and the products have international certification. Quality is our culture, to survive by quality, to develop by integrity. The most perfect quality, the most favorable price, the most intimate service.

Now we mainly offer you the wires products list as various electronic wire harness wiring design, custom vehicle wiring harness, home appliance wire harness, customized industrial wire harness, computer wire harness, over-molded cable connectors, terminal block connectors, power cable types, Products have been widely used in office equipment, communications, household appliances, industrial automation, automobile, etc.

What is Cable Harness?

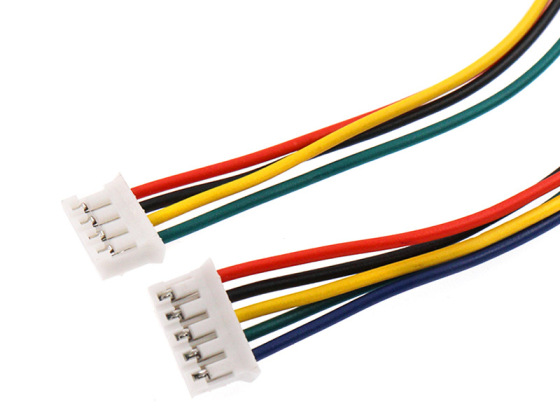

Cable assemblies are groups of cables which are arranged into a single unit for a particular purpose. Cable assemblies are also referred to as cable harnesses or wiring looms.

These cables are grouped together in precisely the required length and orientation in order to make installation easier and quicker. They often include different cable constructions, as well as varying sizes, colours and lengths depending on the application. The assemblies may be compiled with a sleeve applied overall, or taped or bound with cable ties to help group the cables together, protecting them and making them more compact to save space. Depending on the application the assembly may be fitted with various terminations, including plug or socket arrangements.

What is the Wire Harness Assembly Process?

Wire Preparation. Cut the wires to the required lengths based on the design specifications.

.Crimping or Soldering.

Terminal Assembly.

Harness Routing and Bundling.

Testing and Inspection.

Protective Covering

.Labeling and Marking.

Final Quality Check and Packaging.

Where are wiring harnesses used?

Wire harnesses are everywhere — under the hood of every car and truck on the road, and in every plane, jet, and rocket in the sky. Wire harnesses are also referred to as cable harnesses or cable assemblies. These terms all describe a systematic set of cables or wires bundled to form an integrated unit.

wire harness assembly

wire harness connectors

engine wire harness

wire harness kit

wire harness for car

car stereo wire harness

harness wire for car stereo

Metra wire harness

radio wire harness

trailer hitch wire harness

wire harness clips

wire harness radio

3-wire camshaft position sensor wiring harness

5-wire blower motor harness connector

ls wire harness

painless performance wire harness

wire harness manufacturing

custom wire harness

melted caused by fire wire harness