IEC Cable

Product name: AC power cord assembly

Type: 3-slot, 18 AWG x 3C, black

Safety: IEC-60320 (IEC320) C13 to NEMA 5-15P, UL listed

Rated output current: 10 A AMP

Input voltage (AC) 125 V-AC

- Evershine

- Xiamen

- 7~15 days

- 100000pcs/month

- Information

IEC Cable

OEM ODM wiring Harness Factory

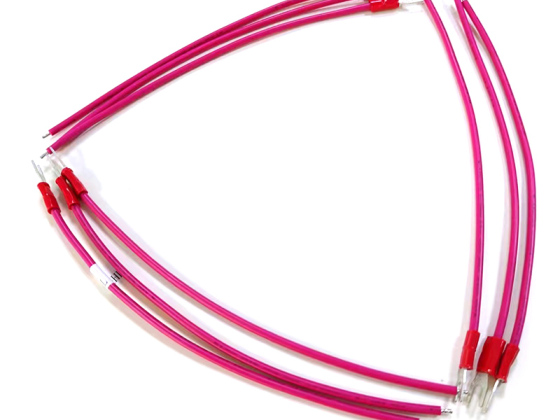

Customized Male to Female Wire Harness

Terminal wire 1.25 air docking Cable Harness

Terminal Wire Harness Kit manufacturer

Custom Cable Assembly

IEC cable is a cable with an IEC connector. You can just tell me what positions you need and what length you need.

IEC connectors refer to electronic cables that conform to IEC standards.

IEC connectors refer to electronic cables that conform to IEC standards. </span>

Connectors mounted by cable are usually called female connectors or sockets, while connectors mounted by panels are called male connectors or plugs.

Power cord assemblies with various plugs

Meets IP67/IP68 waterproof requirements

LOW MOQ 50pcs accepted

The prototype is available, lead time: 1-3 days

An Outline of IEC Cable

Every electronic device successfully functions when connected to a power supply unit. An IEC cable is among the power cables used to supply electronic devices with the power to operate. Examples of such devices include professional audio equipment, computers, and instrument amplifiers.

If you have any of these devices, you must have interacted with an IEC cable even though you are likely not to know more about it. There are varieties of IEC cables which we will discuss and distinguish them with their properties.

IEC Cable Assembly

An IEC cable comprises different wires bound together using the IEC cable assembly. A cable assembly arranges a group of wires or cables into a single unit. IEC cable assembly can also be referred to as wiring loom or cable harness. The IEC cable assembly is significant in different ways;

It protects the wires from external abrasive forces that are likely to expose the conductors, causing electric shorting.

The IEC cable assembly keeps the cables innately together. This makes the installation, repair, and maintenance process quick and easy.

The cable assembly comprises a high-strength material mostly made from PVC.

It’s not easily cut or damaged by high temperatures as it works best within temperatures -40

The insulation material is highly flexible, making it easy to fold the IEC cable without damaging it. Also, it’s resistant to moisture, chemical corrosions, and oil.

Types of IEC Cables

IEC C13/ IEC C14

IEC C13 is an IEC cable with 3-pins (L, N, and E). It’s a connector used on standard mains cable. We use the cable for communications, monitors, computers, and other appliances. It’s the male connection meant to fit in IEC C14 (Female). An IEC C13 is rated to a maximum of 10Amps and 240V. The IEC C14 is a connector normally on IEC extension cables, power supplies, and devices.

IEC C19 /IEC C20

IEC C19 has a 3-pins connection. Its pins are slightly different from those on IEC C13 and IEC C14 connections. The IEC C19 and IEC C20 connectors have a design that enables them to transmit higher current, mostly up to 16Amps. They are shaped differently to ensure other types of connectors can’t connect with them.

IEC Cable Standards

IEC 60331- IEC 60331 gives the specifications on the test method required for cables to maintain circuit integrity in case of fire or any mechanical shock but under particular conditions.

IEC 60332- IEC 60332 provides specific procedures required for testing and evaluating resistance to vertical flame propagation. This looks into a single vertical electrical insulated cable subjected to fire.

IEC 60320 – IEC 60320 comprises the standards by the International Electrotechnical Commission (IEC) providing specifications about the components used to make power supply cables to connect electrical devices up to 250V.

Most often, we use IEC cables at home in household appliances. The cables meet the IEC requirements for approval. They are safe for use with devices with a voltage up to 250V. When using these cables, you don’t need to worry much about your devices. Their safety is catered for.

Company Information:

Xiamen Evershine Electronic Technology Co., Ltd. was founded in 2015, is a professional engaged in wire and cable, wire harness products research and development, production, sales as one of the enterprises, wire and cable widely used in communications, home appliances, power automation, aerospace vehicles, ships, automobiles and so on.

The factory has passed ISO9001 quality management system certification, and the products have international certification. Quality is our culture, to survive by quality, to develop by integrity. The most perfect quality, the most favorable price, the most intimate service.

Now we mainly offer you the wires products list as various electronic wire harness wiring design, custom vehicle wiring harness, home appliance wire harness, customized industrial wire harness, computer wire harness, over-molded cable connectors, terminal block connectors, power cable types, Products have been widely used in office equipment, communications, household appliances, industrial automation, automobile, etc.

What is Cable Harness?

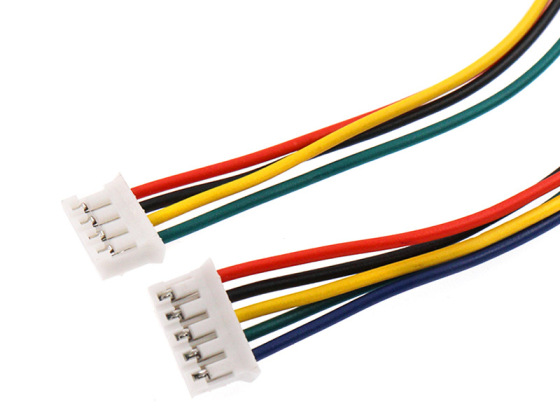

Cable assemblies are groups of cables which are arranged into a single unit for a particular purpose. Cable assemblies are also referred to as cable harnesses or wiring looms.

These cables are grouped together in precisely the required length and orientation in order to make installation easier and quicker. They often include different cable constructions, as well as varying sizes, colours and lengths depending on the application. The assemblies may be compiled with a sleeve applied overall, or taped or bound with cable ties to help group the cables together, protecting them and making them more compact to save space. Depending on the application the assembly may be fitted with various terminations, including plug or socket arrangements.

What is the Wire Harness Assembly Process?

Wire Preparation. Cut the wires to the required lengths based on the design specifications.

.Crimping or Soldering.

Terminal Assembly.

Harness Routing and Bundling.

Testing and Inspection.

Protective Covering

.Labeling and Marking.

Final Quality Check and Packaging.

Where are wiring harnesses used?

Wire harnesses are everywhere — under the hood of every car and truck on the road, and in every plane, jet, and rocket in the sky. Wire harnesses are also referred to as cable harnesses or cable assemblies. These terms all describe a systematic set of cables or wires bundled to form an integrated unit.

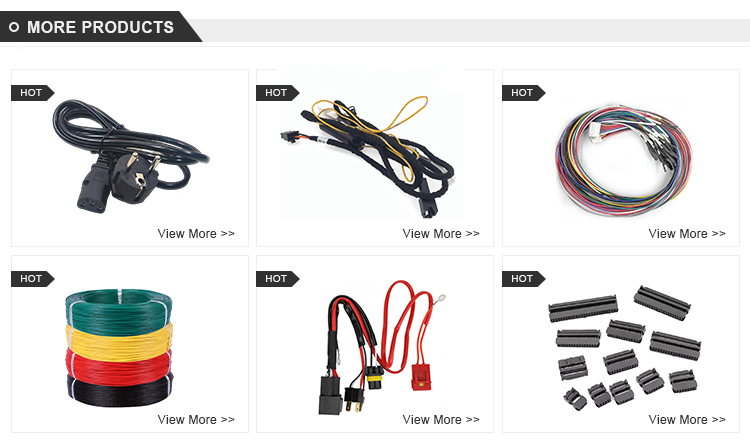

wire harness assembly

wire harness connectors

engine wire harness

wire harness kit

wire harness for car

car stereo wire harness

harness wire for car stereo

Metra wire harness

radio wire harness

trailer hitch wire harness

wire harness clips

wire harness radio

3-wire camshaft position sensor wiring harness

5-wire blower motor harness connector

ls wire harness

painless performance wire harness

wire harness manufacturing

custom wire harness

melted caused by fire wire harness