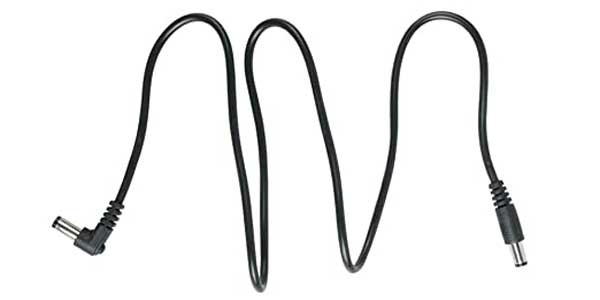

DC cable

Reliable Rubber

Reliable insulating rubber with high temperature resistance 80°C cold resistance – 20°C long service life.

Good Performance

Waterproof, Dustproof, anti-corrosion, flame retardant, anti-oxidation and environmental protection.

Good Conductivity

Adopt a pure copper wire core with strong conductivity and reject the use of inferior pure copper.

Smooth Insertion And Removal

500 times of male female interface connection and plug-in resistance.

- Information

DC cable

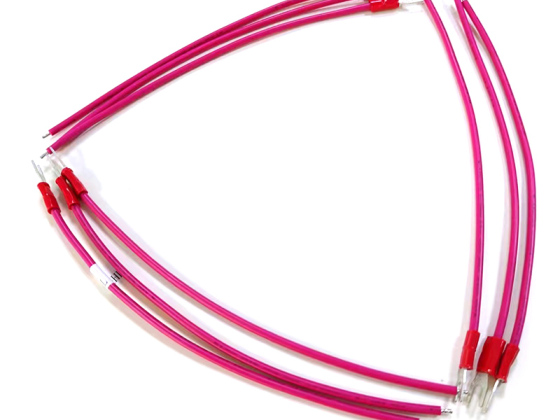

OEM ODM wiring Harness Factory

Customized Male to Female Wire Harness

Terminal wire 1.25 air docking Cable Harness

Terminal Wire Harness Kit manufacturer

Custom Cable Assembly

Comes with Various DC Jack Connectors

What is the features of a DC connector cable?

DC plugs or connectors refer to electrical connectors responsible for supplying direct currents or DC power. This connector is an important component when it comes to DC power chords.

Compared to the normal AC power extension cable, DC power extension cable connectors feature more standard types that are never interchangeable. DC connector cable features a different arrangement and dimension depending on the application. The DC extension cable design helps prevent the possibility of incompatible loads and sources and accidental interconnections while extending the overall length of a standard DC cable.

The DC connectors vary from automotive DC cables to battery packs and portable equipment. DC cable’s main material is normally copper due to its high flexibility nature, thermal performance, and ability to carry current capacities effectively.

The DC cable system is very different from the AC system. DC power cords are used in rectified DC transmission systems. On the other hand, AC cable is often used in power frequency systems.

A DC cable makes it possible to change the power transmission direction while adjusting the current.

A DC cable comes with lots of benefits. To start with, the cable is quite safe to use. This is because the inherent features of a DC power cord transmission make it impossible for the cable to generate any induced current or current leakages. A DC cable will also not have any interference when it comes to the electric field generated by the other cables.

The installation of a DC cable is quite simple and cost-effective. The same applies to the cable’s maintenance.

How to choose a DC cable?

UV radiations

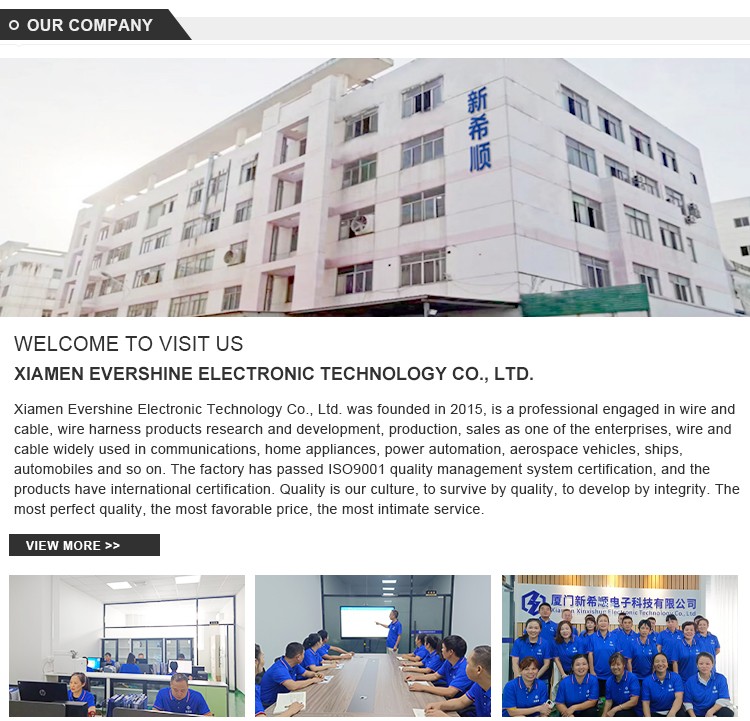

Company Information:

Xiamen Evershine Electronic Technology Co., Ltd. was founded in 2015, is a professional engaged in wire and cable, wire harness products research and development, production, sales as one of the enterprises, wire and cable widely used in communications, home appliances, power automation, aerospace vehicles, ships, automobiles and so on.

The factory has passed ISO9001 quality management system certification, and the products have international certification. Quality is our culture, to survive by quality, to develop by integrity. The most perfect quality, the most favorable price, the most intimate service.

Now we mainly offer you the wires products list as various electronic wire harness wiring design, custom vehicle wiring harness, home appliance wire harness, customized industrial wire harness, computer wire harness, over-molded cable connectors, terminal block connectors, power cable types, Products have been widely used in office equipment, communications, household appliances, industrial automation, automobile, etc.

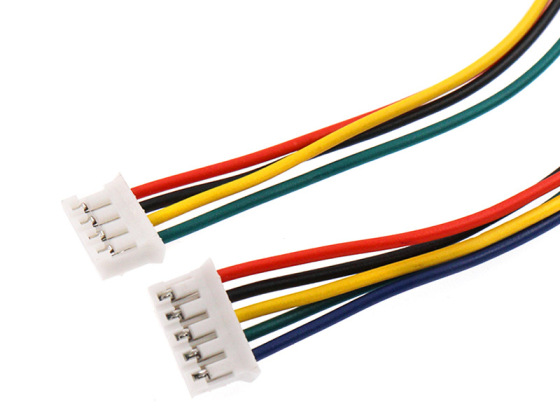

What is Cable Harness?

Cable assemblies are groups of cables which are arranged into a single unit for a particular purpose. Cable assemblies are also referred to as cable harnesses or wiring looms.

These cables are grouped together in precisely the required length and orientation in order to make installation easier and quicker. They often include different cable constructions, as well as varying sizes, colours and lengths depending on the application. The assemblies may be compiled with a sleeve applied overall, or taped or bound with cable ties to help group the cables together, protecting them and making them more compact to save space. Depending on the application the assembly may be fitted with various terminations, including plug or socket arrangements.

What is the Wire Harness Assembly Process?

Wire Preparation. Cut the wires to the required lengths based on the design specifications.

.Crimping or Soldering.

Terminal Assembly.

Harness Routing and Bundling.

Testing and Inspection.

Protective Covering

.Labeling and Marking.

Final Quality Check and Packaging.

Where are wiring harnesses used?

Wire harnesses are everywhere — under the hood of every car and truck on the road, and in every plane, jet, and rocket in the sky. Wire harnesses are also referred to as cable harnesses or cable assemblies. These terms all describe a systematic set of cables or wires bundled to form an integrated unit.

wire harness assembly

wire harness connectors

engine wire harness

wire harness kit

wire harness for car

car stereo wire harness

harness wire for car stereo

Metra wire harness

radio wire harness

trailer hitch wire harness

wire harness clips

wire harness radio

3-wire camshaft position sensor wiring harness

5-wire blower motor harness connector

ls wire harness

painless performance wire harness

wire harness manufacturing

custom wire harness

melted caused by fire wire harness