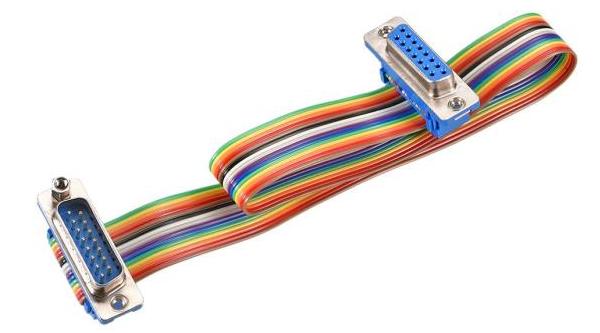

D-SUB Ribbon Cable Description

Generally low voltage

It has a small and lightweight metal shell

It has a shield that controls the RF noises inside from affecting other electronic devices, and it keeps RF signals that are outside from getting in.

Connector mounting is done on the chassis, either the front or back of one of the sides.

The structure used to secure the ribbon cable holds the plate and enables it to provide the perfect securing force.

Has the ability to make easy connections

- Information

D-SUB Ribbon Cable Description

OEM ODM wiring Harness Factory

Customized Male to Female Wire Harness

Terminal wire 1.25 air docking Cable Harness

Terminal Wire Harness Kit manufacturer

Custom Cable Assembly

A D-SUB ribbon cable is a multi-wired cable designed with connectors on one or both ends, used by electronic devices for communication. The name is also in reference to the actual shape of the outer plug or socket, which its mating end resembles the form of the letter “D.”

Basically, in the name D-SUB, the letter “D” indicates the shape of the connector while the word “SUB” is an abbreviation of “SUB-miniature.”

An Overview of D-SUB Ribbon Cable

A lot of people rarely talk or hear about this type of cable. This is because when these cables were in use, most of society only referred them for the connection application they played a part in. Some saw them as monitor cables, others printer cables, mouse cables, joystick cables, and modem cables, just to name a few. However, the D-Sub ribbon cable has many applications within different devices, and this piece will cover just that.

What are the characteristics of the D-SUB ribbon assembly connector?

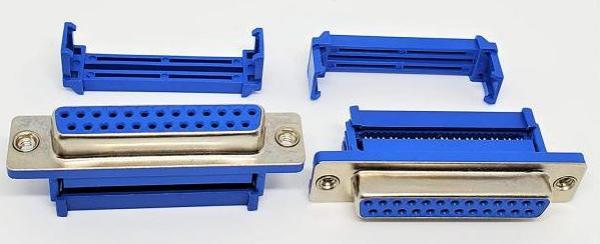

The outer shell design can only be connected in one way, shaped in male or female with two or three rows of pins. Importantly, the strongest feature is that the male connector has screws on each side that thread into the female connector. This keeps them tightly meshed together to protect the pins from corroding by excluding moisture.

What are the types of D-SUB connectors?

D-SUB ribbon cables come in various sizes, including a standard or high density.

In standard density – the cable connectors come in 9-pin, 15-pin, 25-pin, 37-pin, and 50-pin.

In high density – the same size of a standard 9-pin shell turns to 15-pin, a standard 15-pin turns to 26-pin, a standard 25-pin will become 44-pin, a standard 37-pin becomes 62-pin, and a standard 50-pin will turn into 78-pin.

Cables that feature a D-SUB connection

In general, there are several types of cables with these connectors that have been in use for many different applications.

The most common type in consumer electronics is probably the 15 Pin “VGA/XGA” cable (Analog Video interface). This is a blue-colored cable, usually wrapped in a D-shaped metal shield. But let’s look at the other types, specifically the D-SUB ribbon flat cable.

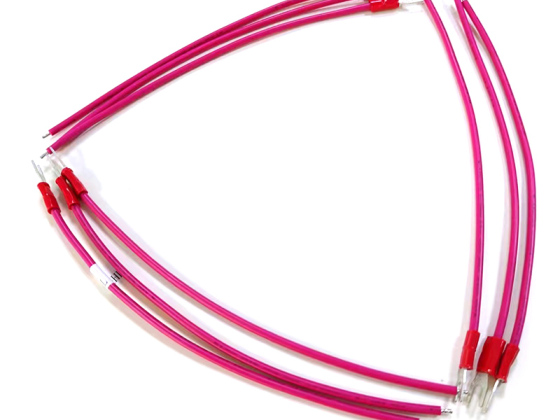

Ribbon cables are flat cables designed with many running conductors laid parallel (side by side). To exhibit a smooth and flat profile, the conductors are properly aligned to respective termination pins and properly seated.

D-SUB ribbon cable end termination

D-SUB flat ribbon cables are properly aligned to orient in the D-SUB connector. The D-SUB flat ribbon cable end does not protrude beyond the connector body edge or violate minimum electrical spacing requirements. This results in the alignment of termination exhibits to the connector fiducially (small notches/marks) and grooves.

What are the application of D-SUB flat ribbon cable

The cable connects different parts of CNC machines and Press Brakes, among others. Its application also includes route control signals for material processing, electronic testing, and much more.

In many instances, the technology market is ever-changing, as newer digital interfaces are now replacing the old ones and making them fade away. Despite all that, there’re still many electrical devices using outdated technologies. Moreover, new devices are being produced to use D-SUB connectors. This makes the D-SUB ribbon cable an important assembly.

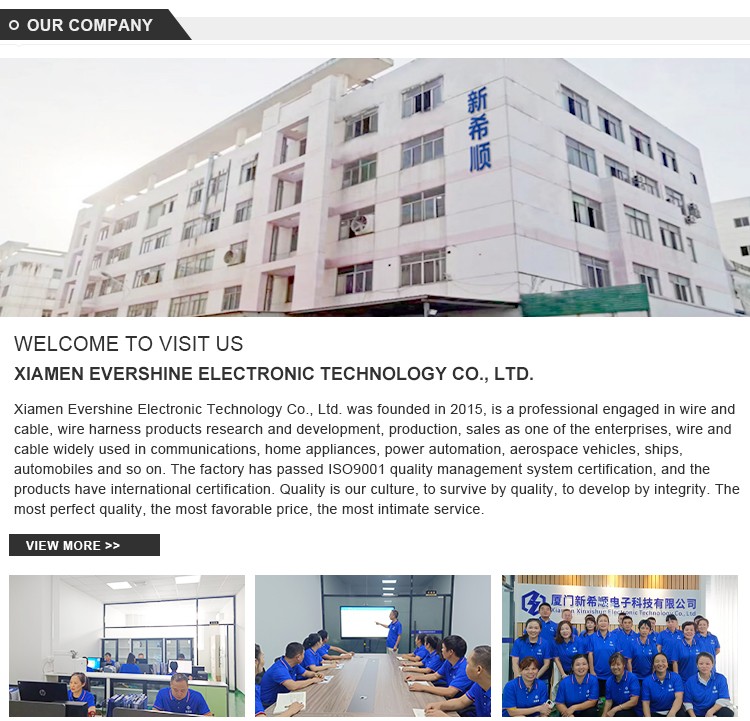

Company Information:

Xiamen Evershine Electronic Technology Co., Ltd. was founded in 2015, is a professional engaged in wire and cable, wire harness products research and development, production, sales as one of the enterprises, wire and cable widely used in communications, home appliances, power automation, aerospace vehicles, ships, automobiles and so on.

The factory has passed ISO9001 quality management system certification, and the products have international certification. Quality is our culture, to survive by quality, to develop by integrity. The most perfect quality, the most favorable price, the most intimate service.

Now we mainly offer you the wires products list as various electronic wire harness wiring design, custom vehicle wiring harness, home appliance wire harness, customized industrial wire harness, computer wire harness, over-molded cable connectors, terminal block connectors, power cable types, Products have been widely used in office equipment, communications, household appliances, industrial automation, automobile, etc.

What is Cable Harness?

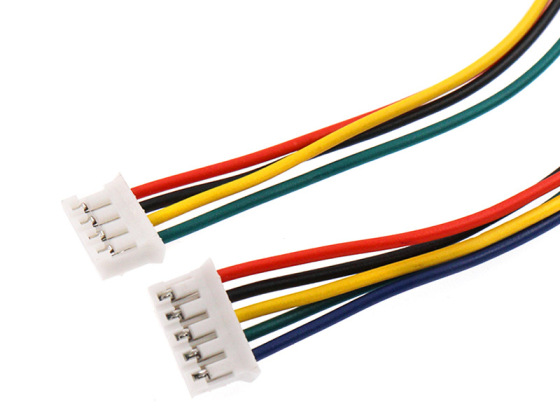

Cable assemblies are groups of cables which are arranged into a single unit for a particular purpose. Cable assemblies are also referred to as cable harnesses or wiring looms.

These cables are grouped together in precisely the required length and orientation in order to make installation easier and quicker. They often include different cable constructions, as well as varying sizes, colours and lengths depending on the application. The assemblies may be compiled with a sleeve applied overall, or taped or bound with cable ties to help group the cables together, protecting them and making them more compact to save space. Depending on the application the assembly may be fitted with various terminations, including plug or socket arrangements.

What is the Wire Harness Assembly Process?

Wire Preparation. Cut the wires to the required lengths based on the design specifications.

.Crimping or Soldering.

Terminal Assembly.

Harness Routing and Bundling.

Testing and Inspection.

Protective Covering

.Labeling and Marking.

Final Quality Check and Packaging.

Where are wiring harnesses used?

Wire harnesses are everywhere — under the hood of every car and truck on the road, and in every plane, jet, and rocket in the sky. Wire harnesses are also referred to as cable harnesses or cable assemblies. These terms all describe a systematic set of cables or wires bundled to form an integrated unit.

wire harness assembly

wire harness connectors

engine wire harness

wire harness kit

wire harness for car

car stereo wire harness

harness wire for car stereo

Metra wire harness

radio wire harness

trailer hitch wire harness

wire harness clips

wire harness radio

3-wire camshaft position sensor wiring harness

5-wire blower motor harness connector

ls wire harness

painless performance wire harness

wire harness manufacturing

custom wire harness

melted caused by fire wire harness