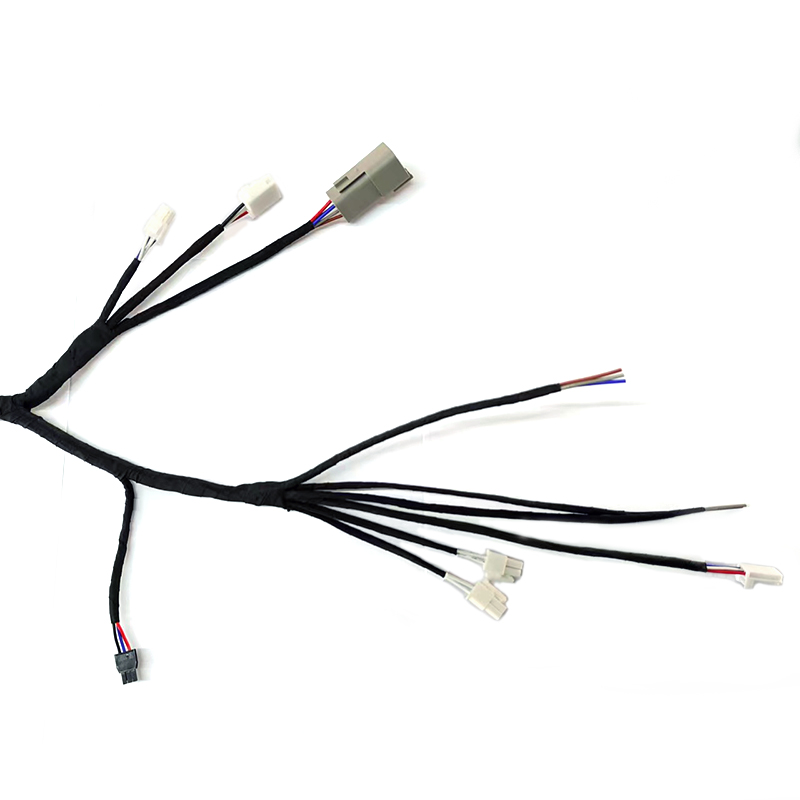

Custom Male to Female Connector Vehicle Wiring Harness

Custom Male to Female Connector Vehicle Wiring Harness.Our custom 24V automotive spot light wiring harness is a tailored cable assembly specifically designed for vehicle lighting enhancement. This high-quality harness ensures a secure and efficient electrical connection for your spot lights, providing superior illumination for various driving conditions. Engineered for reliability and ease of installation, our harnesses are the perfect choice for upgrading your vehicle's lighting system.

- Evershine

- Xiamen

- 7~15 days

- 100000pcs/month

- Information

Q1:How to Choose the Right Vehicle Wiring Harness Manufacturer in China?

Choosing the right vehicle wiring harness manufacturer in China involves considering several key factors. Ensure the supplier has verified certifications like ISO for quality assurance. Look for extensive industry experience and the ability to provide custom solutions tailored to your vehicle needs. Evaluate their manufacturing capacity, lead times, and pricing to ensure reliability and cost-effectiveness. Additionally, check their reputation through reviews or references. Visiting their factory if possible can also provide insight into their production capabilities. Selecting a reputable and experienced manufacturer ensures high-quality wiring harnesses and smooth supply chain operations.

Q2:Trends in USB Cable Manufacturing in 2025

In 2025, USB cable manufacturing is trending towards faster data transfer speeds, increased durability, and enhanced compatibility. Manufacturers are adopting advanced materials and innovative designs to support higher power delivery and multi-device connectivity. There is a growing focus on eco-friendly production processes and sustainable materials to meet environmental standards. Additionally, wireless and magnetic USB cables are gaining popularity, offering more convenience and reducing wear and tear. Overall, the industry is progressing towards smarter, more efficient, and environmentally responsible solutions to meet the evolving demands of consumers and technology.

Q3:Innovations and Trends in Vehicle Wiring Harness Technology

In recent years, vehicle wiring harness technology has seen significant innovations, including the integration of lightweight materials to improve fuel efficiency. Modular designs enable easier installation and maintenance, while smart wiring systems enhance data transmission and vehicle connectivity. Additionally, advances in electromagnetic interference (EMI) shielding improve signal integrity. The adoption of flexible and expandable wiring solutions supports the trend toward electric and autonomous vehicles. Overall, these innovations improve vehicle safety, performance, and efficiency, driving the industry toward smarter and more versatile wiring harness systems for the future.

Q4:Cost Optimization Strategies for Vehicle Wiring Harness Manufacturing

Cost optimization in vehicle wiring harness manufacturing focuses on improving efficiency and reducing waste. Strategies include adopting automated assembly processes to lower labor costs and enhance precision. Using standardized components and modular designs helps streamline production and inventory management. Sourcing materials from reliable suppliers at competitive prices also plays a key role. Additionally, implementing lean manufacturing principles minimizes defects and rework. By balancing quality with cost-effective practices, manufacturers can deliver reliable wiring harnesses while maintaining profitability in a competitive market.

Q5:Certifications and Standards to Expect from a USB Cable Manufacturer

When choosing a USB cable manufacturer, expect certifications like ISO 9001 for quality management and RoHS compliance to ensure environmentally safe materials. USB-IF certification guarantees adherence to USB standards for performance and compatibility. Additionally, CE and FCC marks indicate compliance with safety and electromagnetic interference regulations. These certifications ensure the cables meet global quality, safety, and environmental standards, providing reliable and durable products. Verifying these credentials helps buyers select reputable manufacturers committed to high standards and customer satisfaction.

Q6:Future Developments in Vehicle Wiring Harness Design and Manufacturing

Future developments in vehicle wiring harness design focus on lightweight, flexible materials to enhance fuel efficiency and accommodate compact vehicle architectures. Advanced manufacturing techniques like 3D printing and automation will increase precision and reduce production time. Integration of smart sensors and real-time diagnostics will improve maintenance and safety. Additionally, designs will support the growing demand for electric and autonomous vehicles, emphasizing higher data transmission speeds and robust connectivity. These innovations will drive smarter, more efficient, and sustainable wiring harness solutions for the automotive industry’s evolving needs.

Q7:How to Ensure Reliability and Durability in Vehicle Wiring Harnesses

Ensuring reliability and durability in vehicle wiring harnesses involves using high-quality materials resistant to heat, moisture, and vibration. Proper insulation and shielding protect against electrical interference and corrosion. Rigorous testing, including thermal cycling and mechanical stress tests, verifies performance under harsh conditions. Additionally, precise assembly techniques and secure connectors prevent failures. Regular quality control throughout manufacturing ensures consistent standards. These measures collectively enhance the lifespan and safety of wiring harnesses, supporting vehicle reliability and reducing maintenance costs.

Q8:Why Are Wire Harnesses Assembled Manually?

Wire harness assembly process is one of the few remaining manufacturing processes that is more efficiently done by hand, rather than automation.

This is due to the variety of processes that are involved in the assembly. These manual processes include:Installing terminated wires in various lengths Routing wires and cables through sleeves and conduits,Taping breakouts Conducting multiple crimps.Binding the components with tape, clamps or cable ties because of the difficulty involved in automating these processes, manual production continues to be more cost-effective, especially with small batch sizes.

This is also why harness production takes longer than other types of cable assemblies. Production can take anywhere from a few days to several weeks.

The more complicated the design, the longer production time is required.While it's possible to protect your wiring harness from the elements using electrical tape, silicone, or even heat shrink ,creating a custom-made waterproof wiring harness is the only way you will know for sure that it is protected.

Waterproof Automotive Electrical Connectors Electrical Wire Connectors Plug Kit multi Pin Waterproof Connectors with Ratchet Crimping Tool.

Q9:What is a waterproof wire harness?

Waterproof Automotive Electrical Connectors Electrical Wire Connectors Plug Kit multi Pin Waterproof Connectors with Ratchet Crimping Tool.

While it's possible to protect your wiring harness from the elements using electrical tape, silicone, or even heat shrink , creating a custom-made waterproof wiring harness is the only way you will know for sure that it is protected.

Q10:How to make a waterproof wire harness ?

Use Liquid Electrical Tape

Use self-Fusing Silicone Tape

Adhesive lined heat shrink tube.

Heat gun.

Q11:Can you reuse waterproof wire connectors?

You would not reuse waterproof wire connectors. Typical installation for the grease tube is to push the decoder and solenoid wire into the wire nut, twist it, insert the wire nut all the way into the tube, and lock the lid into place. Note: Turn off power before installing or removing waterproof wire connectors.