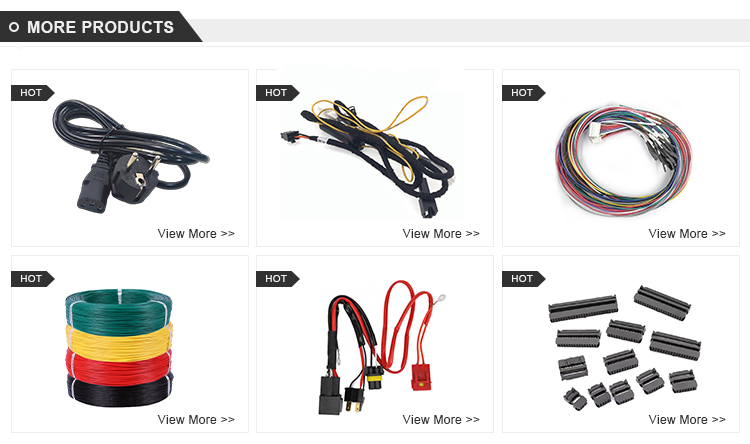

China professional automotive cable Harness assemblies manufacturer

China professional automotive cable Harness assemblies manufacturer.We provide custom high-quality automotive cable components Wire Harness and fuse safety harnesses by leveraging our status as a professional manufacturer.

Our precision-engineered solutions wiring harness are tailored to meet the specific requirements of various automotive applications, ensuring the utmost safety and reliability. With a focus on quality and customization, we offer a comprehensive range of services, including design, assembly, and testing, to deliver the best possible product for your vehicle's electrical system needs.

- Evershine

- Xiamen

- 7~15 days

- 100000pcs/month

- Information

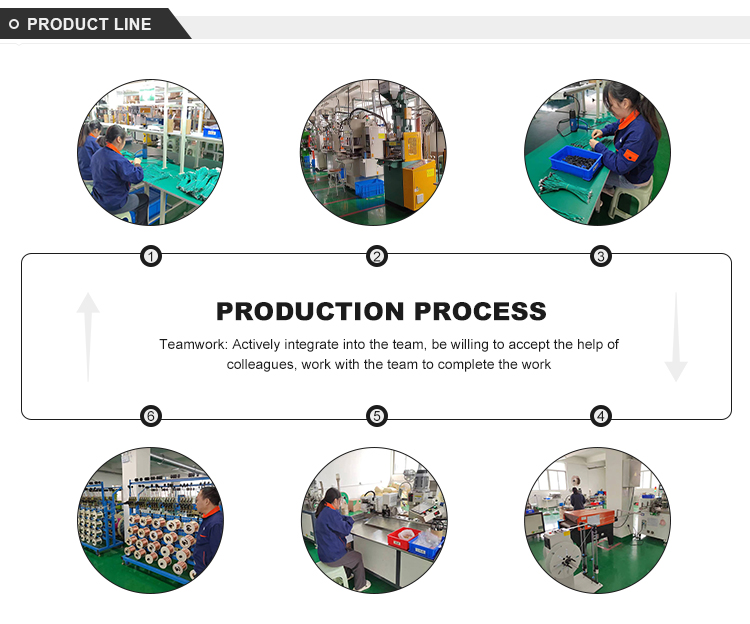

Wire harness assembly process is one of the few remaining manufacturing processes that is more efficiently done by hand, rather than automation.

This is due to the variety of processes that are involved in the assembly. These manual processes include:

Installing terminated wires in various lengths Routing wires and cables through sleeves and conduits,Taping breakouts

Conducting multiple crimps.Binding the components with tape, clamps or cable ties

ecause of the difficulty involved in automating these processes, manual production continues to be more cost-effective, especially with small batch sizes.

This is also why harness production takes longer than other types of cable assemblies. Production can take anywhere from a few days to several weeks.

The more complicated the design, the longer production time is required.

While it's possible to protect your wiring harness from the elements using electrical tape, silicone, or even heat shrink ,

creating a custom-made waterproof wiring harness is the only way you will know for sure that it is protected.

Waterproof Automotive Electrical Connectors Electrical Wire Connectors Plug Kit multi Pin Waterproof Connectors with Ratchet Crimping Tool.

Wire Harnesses vs. Cable Assemblies

Wire harnesses are often confused with cable assemblies however, the two are quite different. The main difference is that a cable assembly normally has only two ends, whereas a wire harness contains multiple breakouts (ends) that run in many different directions with multiple terminations on each breakout.

Wire assemblies are most commonly used in the transportation industry, including automobiles, buses, trucks, and planes. Construction machinery, industrial equipment, electronics and white goods (household appliances) will also be constructed using wire harnesses.

Wire Harness Assembly Process

1.Wire Preparation. Cut the wires to the required lengths based on the design specifications.

2.Crimping or Soldering. ...

3.Terminal Assembly. ...

4.Harness Routing and Bundling. ...

5.Testing and Inspection. ...

6.Protective Covering. ...

7.Labeling and Marking. ...

8.Final Quality Check and Packaging.

Our Advantages:

1. One-stop supply.

2. Leadtime is short: within 3~10days after products details confirmed.

3. High quality with price policy: We service many top customers . These customers strictly require in

products quality and company management system.All our products quality is same level.

Price Policy:

We supply good price not only to end customer,but also same to trade company.